Laser forming machine

A forming machine and laser technology, applied in the field of additive manufacturing, can solve the problems of increased section size of forming cylinder, inconvenient operation, high forming surface height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

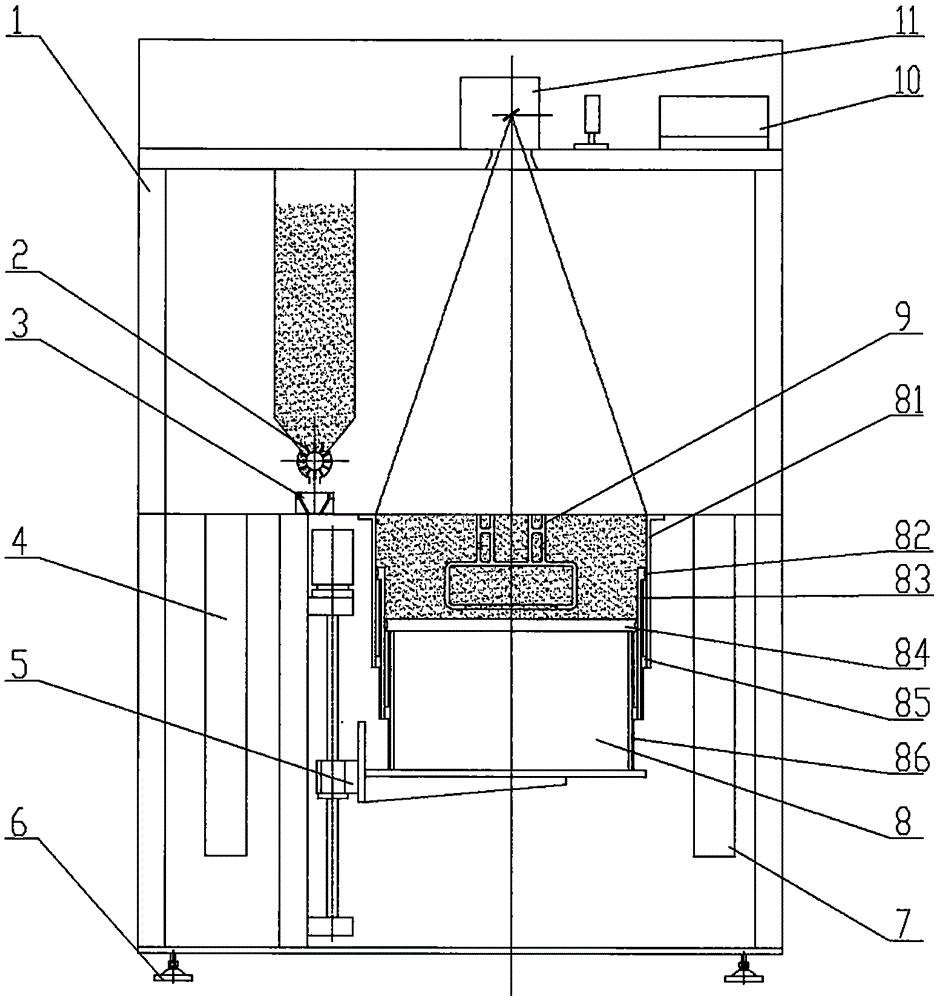

[0019] refer to figure 1 Shown, this embodiment is a two-section telescopic cylinder form. The outermost telescopic cylinder 81 is fixed to the worktable and the frame, and the upper end between the outermost telescopic cylinder 81 and the innermost telescopic cylinder 83 is sealed by a seal 82, and the lower end is guided by a cylinder moving guide device 85, and the piston is guided by the piston. The motion drive system drives the innermost telescopic cylinder 83 to move up and down, which not only ensures the reliable sealing of the forming cylinder, but also, under the same height of the working table, the piston stroke can be lengthened compared with the usual single cylinder, so that Parts with larger dimensions in the height direction can be processed.

[0020] What has been described above are only preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle and core idea of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com