Alkali-free glass fiber woven roving stitch-bonded compound felt

An alkali-free glass fiber and stitch-bonded composite mat technology is applied in the field of composite mats, which can solve the problems of limiting the application of alkali-free glass fiber fabrics, large strength loss, small relative elongation, and electrical insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

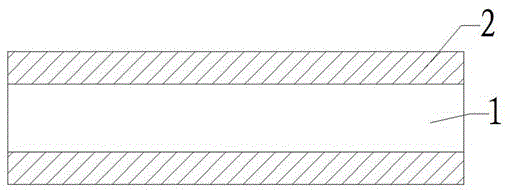

[0014] see figure 1 , the embodiment of the present invention comprises: a kind of non-alkali glass fiber check cloth stitch-bonded composite felt, comprises non-alkali glass fiber check cloth layer 1, and described non-alkali glass fiber check cloth layer 1 is stitched with flame-retardant Layer 2, the flame-retardant layer 2 provides flame-retardant ability for the non-alkali glass fiber grid layer 1, so that the non-alkali glass fiber grid cloth stitching composite mat overcomes the non-alkali glass fiber fabric. Defects in applications such as high temperature, fire prevention, and flame retardancy.

[0015] The non-alkali glass fiber grid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com