Composite side window glass

A kind of window glass and composite technology, applied in the direction of glass/slag layered products, transparent/reflective heating devices, layered products, etc., can solve the problems that cannot meet the safety requirements, achieve excellent mechanical properties and prolong service life , the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of a composite side window glass and its preparation method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Mode, structure, feature and effect thereof are as follows in detail. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

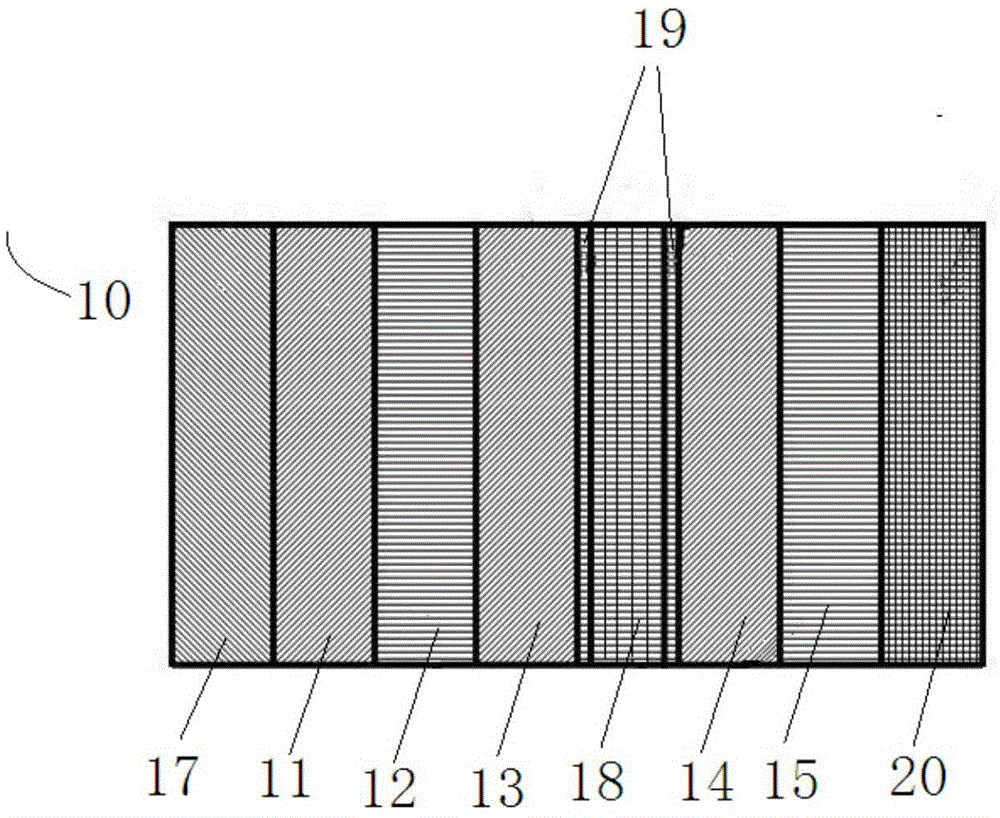

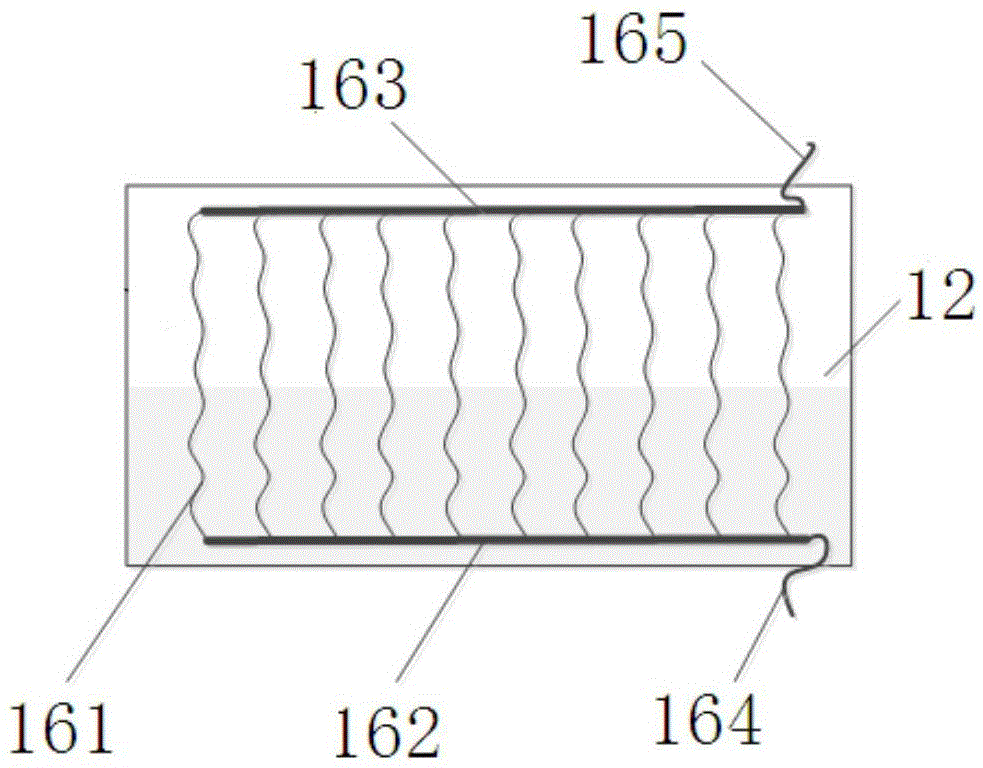

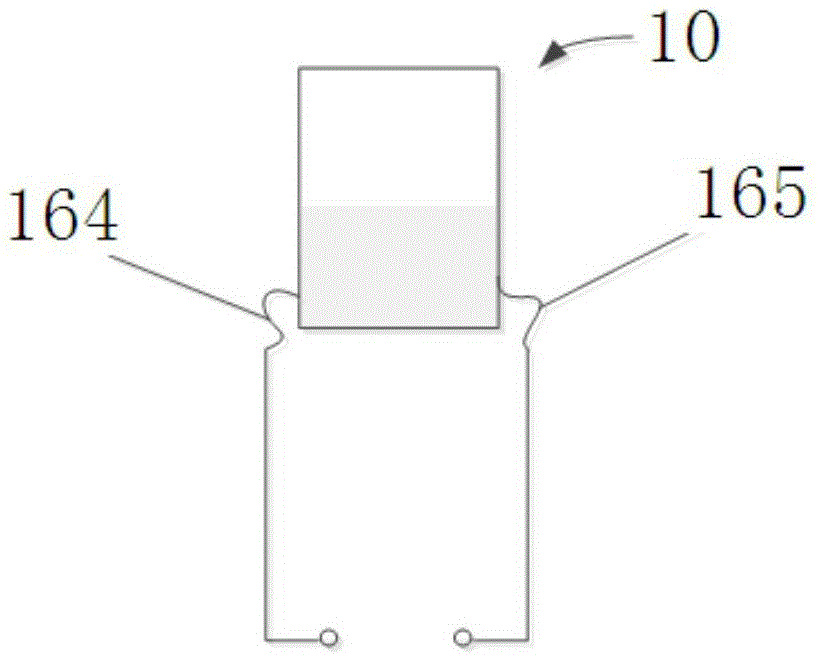

[0038] like figure 1As shown, an embodiment of the present invention proposes a side window glass, which is applied to high-speed locomotives, especially high-speed locomotives with a speed exceeding 380 km / h. The side window glass 10 includes: a first glass layer 11 , a first film layer 12 , a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com