Bitumen composition particles and preparation method thereof

A technology of asphalt composition and granules, which is applied in the field of high softening point asphalt composition granules and its preparation, can solve the problems of no organic whole, difficult dispersion of water-based drilling fluid, coalescence, etc., and achieves increased deformability, Increase the use range of viscoelasticity and reduce the effect of high temperature and high pressure filter loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

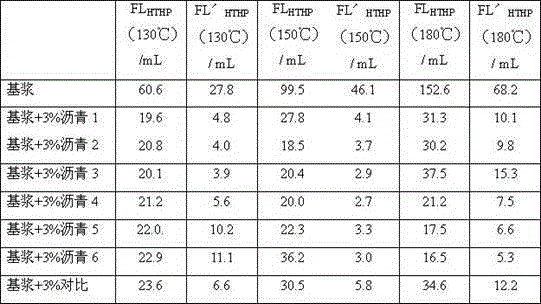

Examples

Embodiment 1

[0033] Take 100 g of oxidized pitch whose softening point is 146.5° C., and heat it to a molten state. Take 75 g of waste tire rubber powder with a particle size of 100 mesh, and preheat it at 100° C. for 40 minutes. Put the melted high softening point asphalt in the watering can, evenly spray the high softening point asphalt on the preheated rubber powder particles, and stir while spraying. After spraying, it was left to stand at 135° C. for 30 minutes, and then cooled to room temperature. Then place it in a freezer to freeze (freezing temperature -35°C, freezing time: 12 hours). After taking it out, put it into a vibrating sieve, use an 80-mesh standard sieve as the bottom of the sieve, vibrate and pulverize it for 20 seconds, and get the modified high softening point asphalt particles under the sieve. Another 80g of styrene-butadiene latex (solid content 40%) was placed in a watering can, and the latex was evenly sprayed onto the asphalt particles obtained in the above te...

Embodiment 2

[0035]Take 100g of deasphalt with a softening point of 157.2°C and heat it to a molten state. Take 46g of waste tire rubber powder with a particle size of 120 mesh, preheat at 105°C for 30 minutes, and add 7.2g of hydrotalcite. Put the melted high softening point asphalt in the watering can, evenly spray the high softening point asphalt on the preheated rubber powder particles, and stir while spraying. After spraying, it was left to stand at 155° C. for 40 minutes, and cooled to room temperature. Then place it in a freezer for freezing (freezing temperature -25°C, and freezing time for 14 hours). After taking it out, put it into a vibrating sieve, use a 100-mesh standard sieve as the bottom of the sieve, vibrate and pulverize it for 35 seconds, and get the modified high softening point asphalt particles under the sieve. Another 72g of neoprene latex (solid content 30%) was placed in a watering can, and the latex was evenly sprayed onto the asphalt particles obtained in the a...

Embodiment 3

[0037] Take 100g of natural asphalt with a softening point of 138.8°C and heat it to a molten state. Take 52 g of waste tire rubber powder with a particle size of 100 mesh, and preheat it at 95° C. for 45 minutes. Put the melted high softening point asphalt in the watering can, evenly spray the high softening point asphalt on the preheated rubber powder particles, and stir while spraying. After spraying, it was left to stand at 125° C. for 55 minutes, and cooled to room temperature. Then place it in a freezer to freeze (freezing temperature -40°C, and freezing time is 10 hours). After taking it out, put it into a vibrating sieve, use an 80-mesh standard sieve as the bottom of the sieve, vibrate and pulverize it for 30 seconds, and get the modified high softening point asphalt particles under the sieve. Another 96g of nitrile latex (30% solid content) was placed in a watering can, and the latex was evenly sprayed onto the asphalt particles obtained in the above test, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com