Frame sealant, liquid crystal panel, liquid crystal display and preparation method

A technology of liquid crystal panel and frame sealant, which is applied in bonding methods, instruments, adhesives, etc., can solve the problems that glass fibers and gold ball particles cannot be uniformly dispersed, the display effect of liquid crystal panel is affected, and the support force of frame sealant is different. Achieve the effect of preventing the penetration of small molecules, avoiding the puncture phenomenon of liquid crystal molecules, and avoiding gap defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

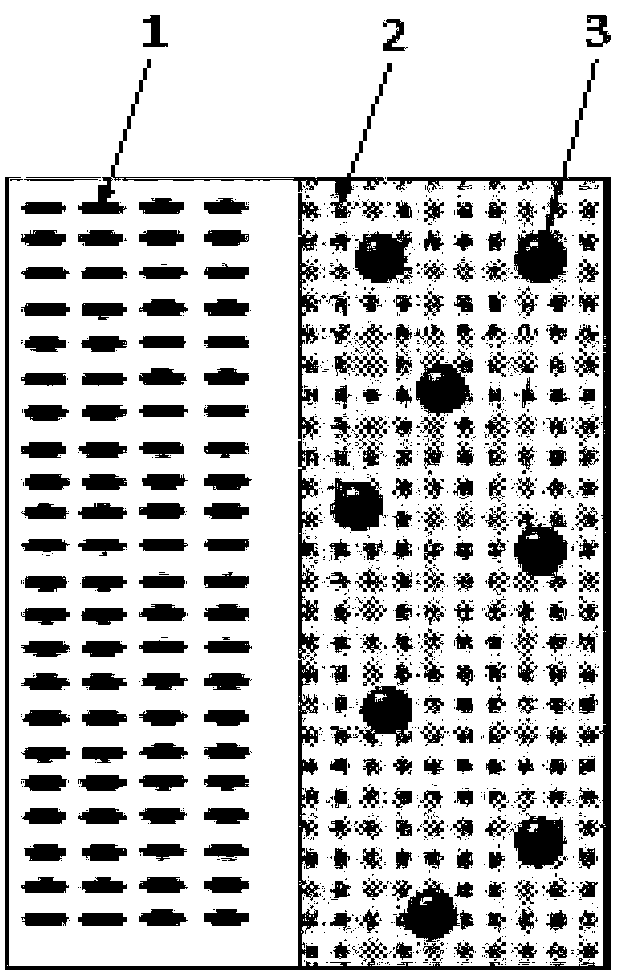

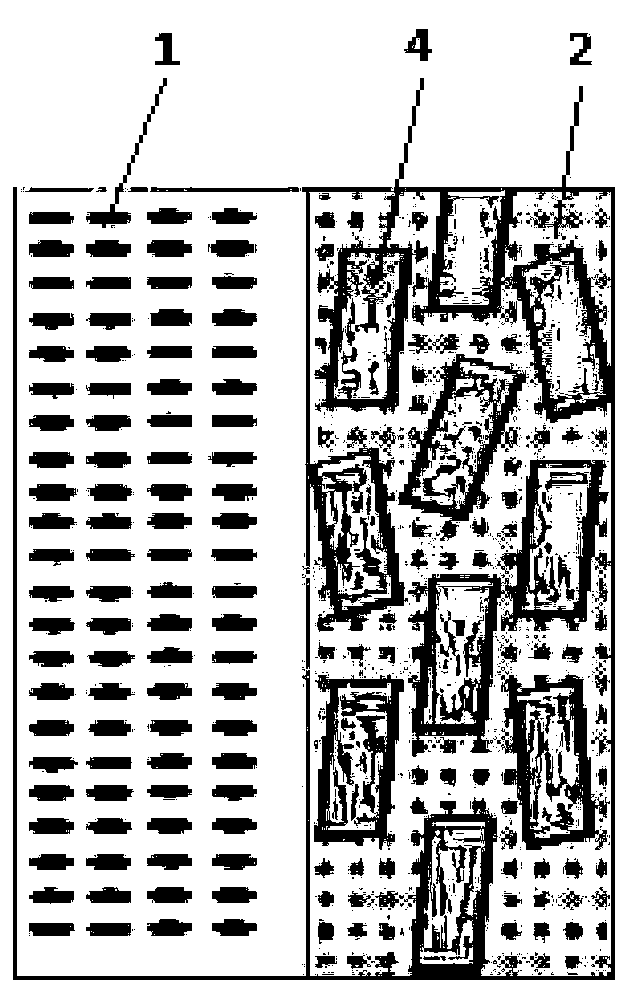

[0061] In a fourth aspect, an embodiment of the present invention provides a method for preparing a liquid crystal panel, the method comprising the following steps:

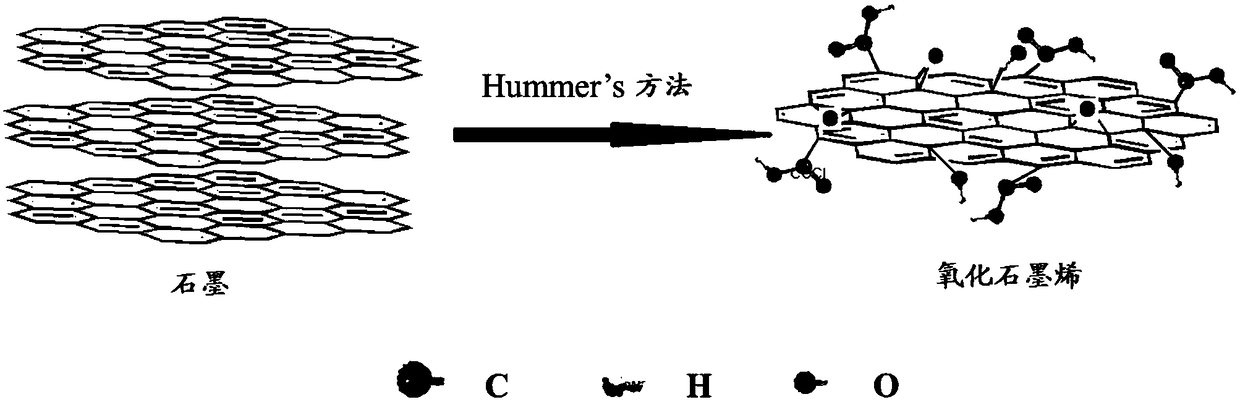

[0062] Step 1, uniformly mixing the frame sealing glue matrix and graphene oxide to obtain a mixture;

[0063] Step 2, the mixture is subjected to defoaming treatment under light-proof conditions;

[0064] Step 3, coating the degassed mixture obtained in step 2 on the frame of the color filter substrate;

[0065] In step 4, the array substrate dripped with liquid crystal and the color filter substrate obtained in step 3 are boxed together, and the liquid crystal panel is obtained after ultraviolet polymerization and thermal polymerization.

[0066] In this preparation method, the sealant used to bond the array substrate and the color filter substrate is a sealant containing graphene oxide. Graphene oxide not only has good support and conductivity, but also has good barrier properties, and It has good compatibil...

Embodiment 1

[0078] This embodiment provides a frame sealant, which includes the following components in mass fraction:

[0079] Graphene oxide, 2%;

[0080] Epoxy acrylic resin, 25%;

[0081] Acrylics, 48%;

[0082] Diaminodiphenylmethane, 15%;

[0083] Acetophenone, 0.5%;

[0084] Organic filler, 5%;

[0085] Vinyltriethoxysilane, 4.5%.

[0086] In this embodiment, the sheet size of graphene oxide is 6 microns, and the sheet thickness is about 1 nm.

[0087] It should be noted that those skilled in the art can understand that the size of the graphene oxide sheet that is made is not an absolute concept, but can be understood as a range, for example, the sheet of graphene oxide prepared by the above method is mostly ( At least half of it) can be controlled in the range of about 6 microns.

Embodiment 2

[0089] This embodiment provides a frame sealant, which includes the following components in mass fraction:

[0090] Graphene oxide, 10%;

[0091] Epoxy acrylic resin, 30%;

[0092] Acrylic resin, 35%;

[0093] Diaminodiphenylmethane, 15%;

[0094] Acetophenone, 0.5%;

[0095] Organic filler, 5%;

[0096] Vinyltriethoxysilane, 4.5%.

[0097] In this embodiment, the sheet size of graphene oxide is 7 microns, and the sheet thickness is about 1 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com