Flame-retardant high-weather-resistance polysulfide sealant and preparation method thereof

A polysulfide sealant, high weather resistance technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as potential safety hazards, flammable raw materials, and reduced sealant strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

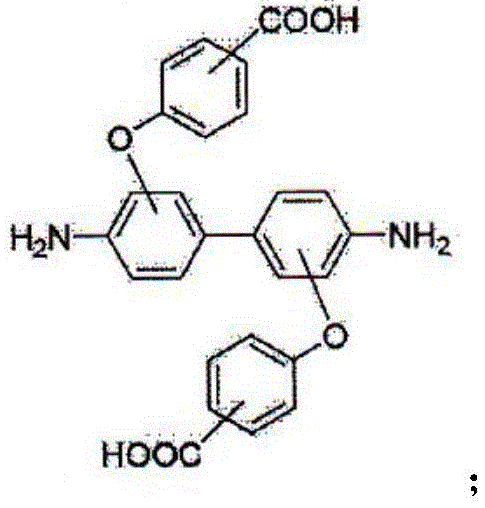

[0044] In one embodiment, the preparation method of the silane modified hyperbranched polyimide comprises:

[0045] (1) Preparation of amino-terminated hyperbranched polyimide

[0046]In a dry three-necked flask, sequentially add 1 mmol of triamine, 1 to 1.3 mmol of dianhydride, 2 mmol of benzoic acid, 0.5 to 3 mL of isoquinoline and 10 to 500 mL of a good organic solvent; , heat up to 100-160°C for 1-4 hours, then heat up to 180-220°C for 2-20 hours; after the reaction, cool down to room temperature and pour the reaction solution into methanol to precipitate a large amount of solid; After repeated washing, filter with suction and dry the collected solid in a vacuum oven at 30-80°C for 2-10 hours to obtain amino-terminated hyperbranched polyimide;

[0047] (2) Preparation of silane-modified hyperbranched polyimide

[0048] Add 10 parts by weight of the above-mentioned amino-terminated hyperbranched polyimide, 1-30 parts by weight of epoxy silane coupling agent KH-5600 and an...

Embodiment 1

[0119] Component A: Add A1100 parts by weight, B110 parts by weight, C120 parts by weight, D15 parts by weight, E12 parts by weight and F11 parts by weight into a vacuum-tight mixer and mix thoroughly for 30 minutes;

[0120] Component B: Add G1100 parts by weight, H12 parts by weight, I110 parts by weight, B12 parts by weight, F12 parts by weight, J12 parts by weight and K12 parts by weight into the vacuum sealed mixer, and mix thoroughly for 30 minutes;

[0121] Ratio A:B=10:1, mix evenly; when using, mix A and B components in proportion, apply within 2 hours, and completely cure within 5 hours at room temperature.

Embodiment 2

[0123] Component A: Add A1100 parts by weight, B130 parts by weight, C130 parts by weight, D115 parts by weight, E110 parts by weight and F110 parts by weight into a vacuum-tight mixer, and mix thoroughly for 30 minutes;

[0124] Component B: Add 100 parts by weight of Gl, 10 parts by weight of Hl, 140 parts by weight of I, 110 parts by weight, F110 parts by weight, J110 parts by weight and K110 parts by weight into a vacuum-tight mixer, and mix thoroughly for 30 minutes;

[0125] Ratio A:B=10:1, mix evenly; when using, mix A and B components in proportion, apply within 2 hours, and completely cure within 5 hours at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com