A kind of active rust layer rust transfer agent for power transmission and transformation equipment and its preparation method and application

A technology of power transmission and transformation equipment and rust transfer agent, which is applied in the coating process of metal materials, etc., can solve the problems of difficult to meet the requirements, serious damage to the iron matrix, and harsh service conditions, so as to improve the quality of surface treatment and reduce the cost of surface treatment. Difficulty and the effect of improving the corrosion resistance life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

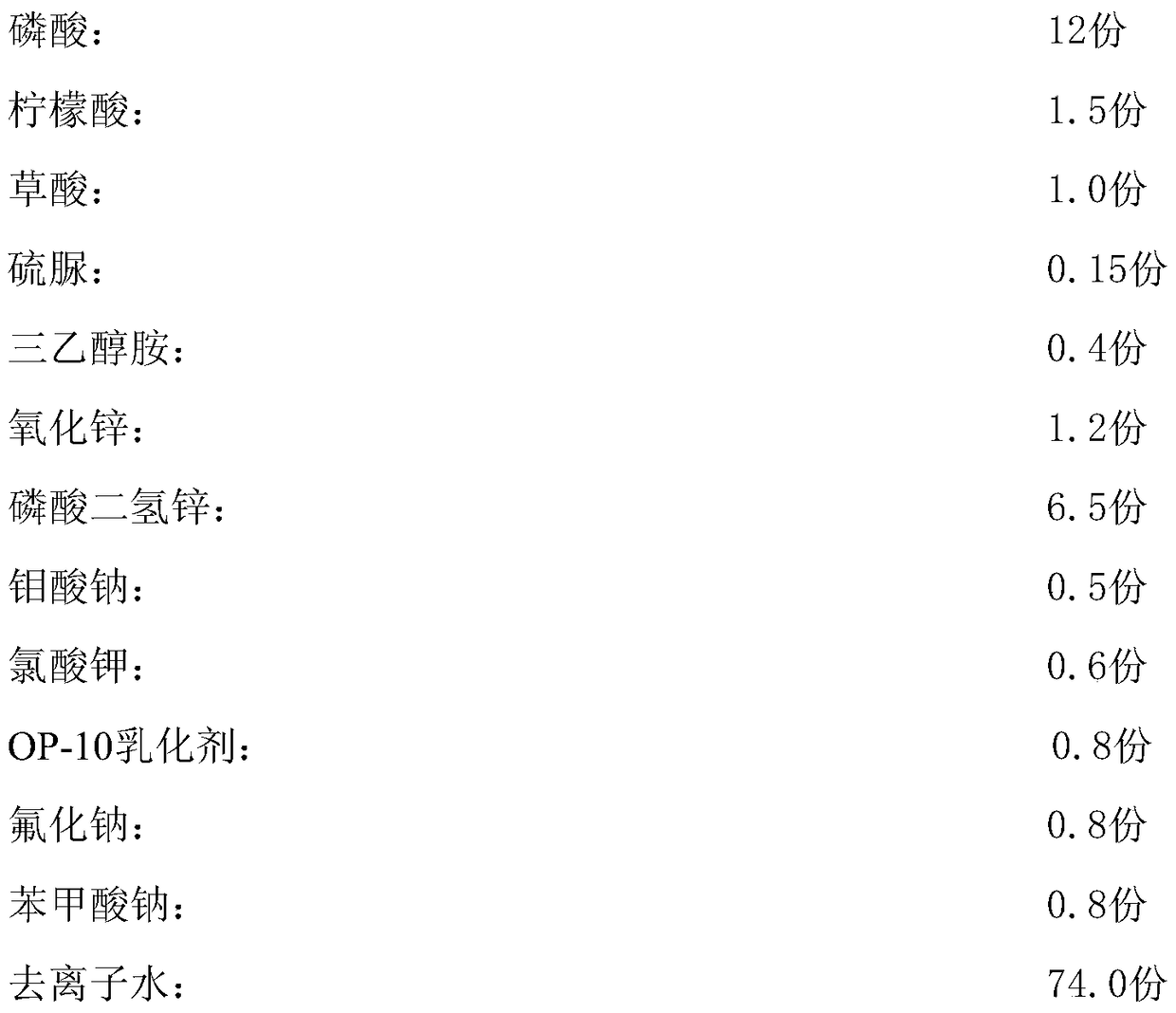

[0056] 1. Prepare the materials according to the following mass ratio, and the chemical reagents are all analytically pure:

[0057]

[0058] 2. Product preparation:

[0059] Step 1. Mix 12 parts of phosphoric acid with 12 parts of deionized water, wait to be cooled, and set aside.

[0060] Step 2. Put 62 parts of deionized water into a beaker, and use SWFS-400 laboratory high-speed disperser to stir. The stirring speed is set to 600r / min. Under the stirring state, the zinc dihydrogen phosphate and zinc oxide are proportioned. , Potassium chlorate, sodium molybdate, sodium fluoride, sodium benzoate, citric acid, oxalic acid, thiourea, triethanolamine, OP-10 were added in sequence, stirred for 30 minutes, then added the phosphoric acid prepared in step 1, and continue to stir for 30 minutes. The product is obtained when the solution is transparent and free of impurities.

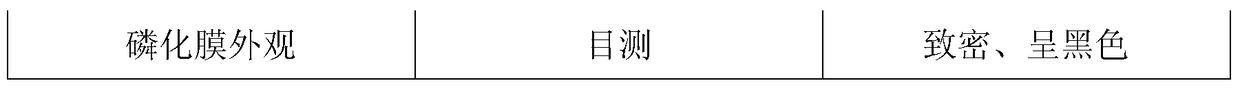

[0061] 3. Performance test:

[0062] Perform performance tests on the prepared products, and the data is as follow...

Embodiment 2

[0074] Phosphoric acid: 15 parts

[0075] Deionized water: 71 parts

[0076] Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com