Fine denier sewing thread purpose terylene industrial yarn and processing equipment thereof

A technology of polyester industrial yarn and processing equipment, applied in the field of fiber processing, can solve the problems of inability to spin, insufficient stretch of civilian yarn, low breaking strength, etc., and achieve the effect of ensuring uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

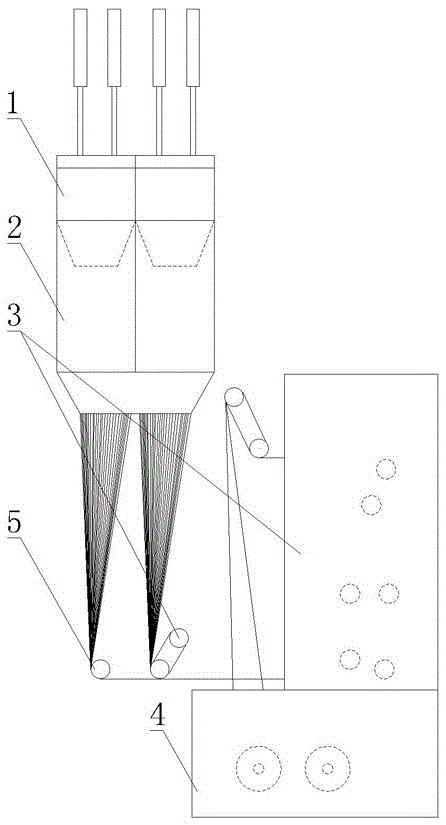

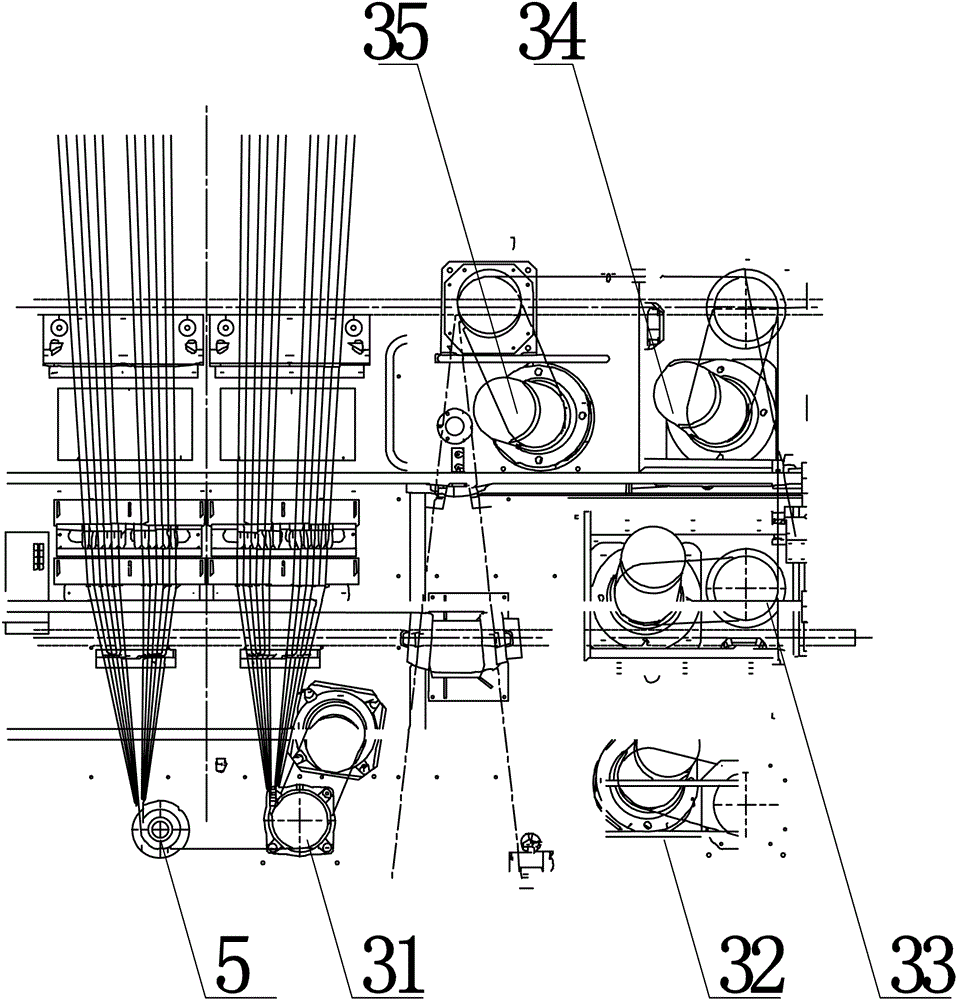

[0034] A kind of processing equipment of polyester industrial yarn for fine denier sewing thread in this embodiment, combined with figure 1 , from top to bottom is composed of spinning box 1, post heater, spinning tunnel 2, drafting heat setting mechanism 3 and winding mechanism 4, and the drafting heat setting mechanism adopts five pairs of rollers. figure 2 , the first pair of rollers 31 is a cold roller, the second pair of rollers 32 and the third pair of rollers 33 are medium temperature rollers, the fourth pair of rollers 34 is a secondary high temperature roller; the fifth pair of rollers 35 is a high temperature roller.

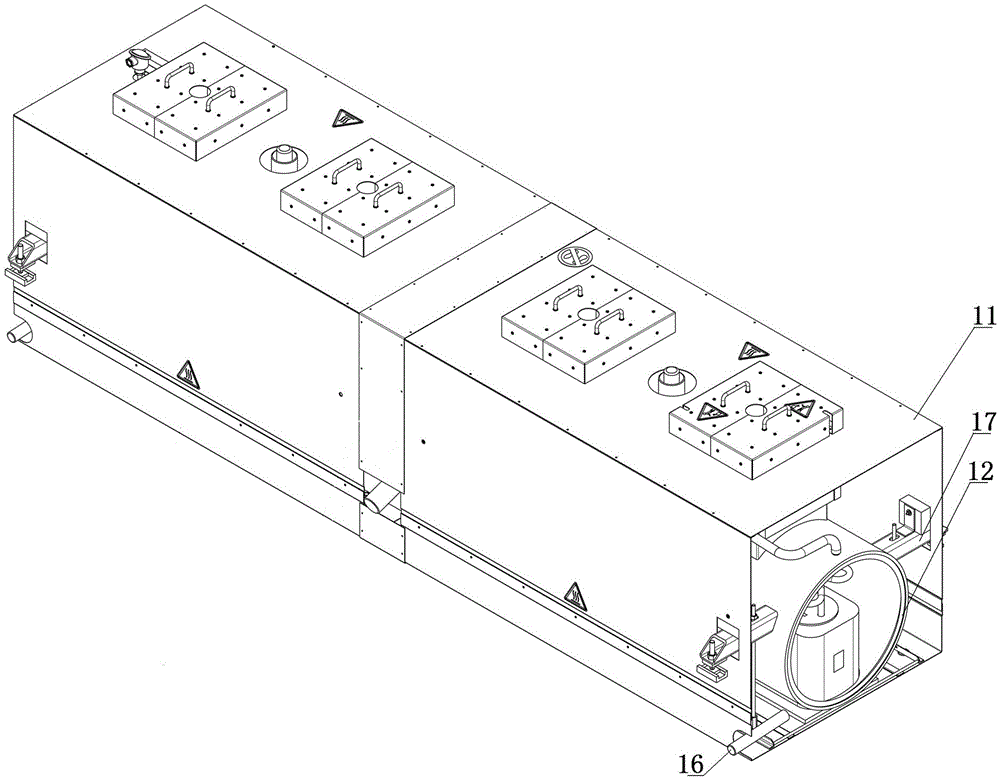

[0035] combine Figure 3-6 , the spinning box 1 is composed of an outer box 11, an inner cylinder 12, a metering pump, a melt pipe 13, a melt distribution pipe 18 and a spinning assembly 14, the outer box 11 is set on the inner cylinder 12, and the To keep the inner cylinder warm, the outer box 11 is composed of an upper cover 111, (left and right) s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com