A floating net vortex elimination method used before the water inlet

A water inlet and floating net technology, applied in the field of floating net vortex elimination, can solve the problems of difficult to predict the vertical axis vortex phenomenon of the water inlet, unable to guarantee effective control and elimination, large amount of engineering, etc., to achieve strong practical scope and use value, Conducive to popularization and application, the effect of small amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

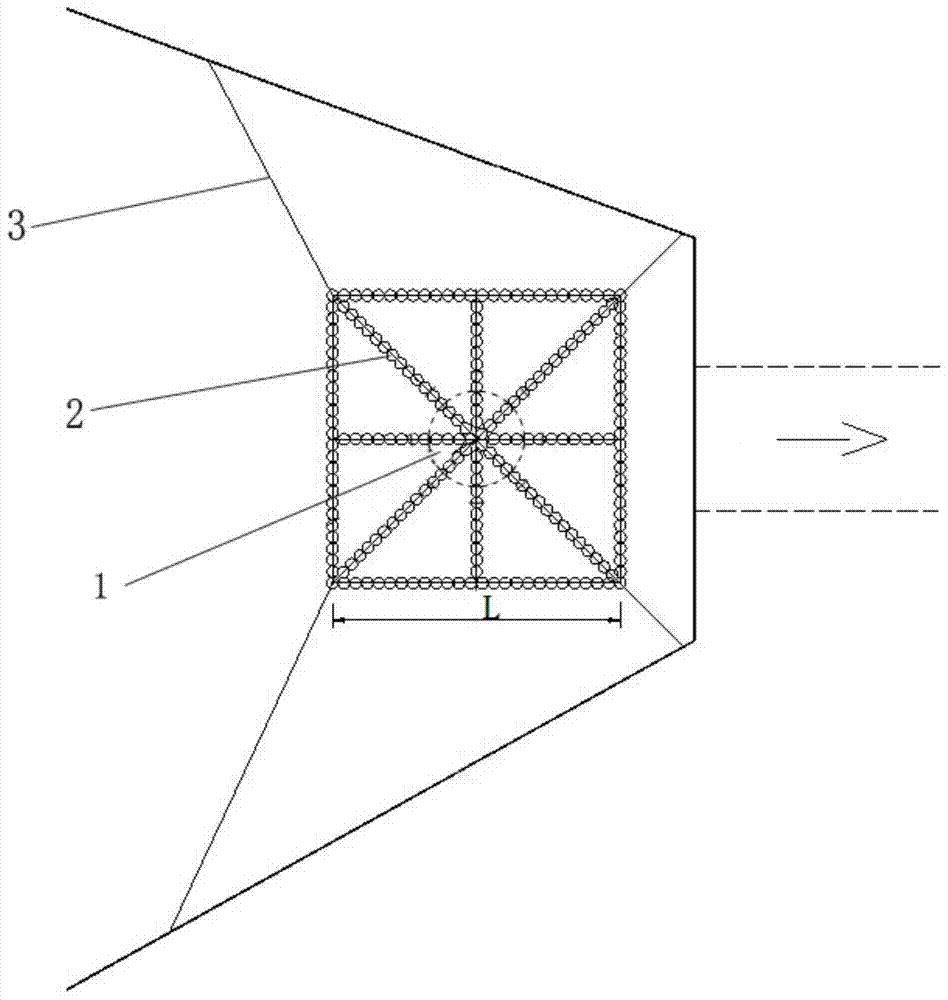

[0024] figure 2 It is a schematic diagram of the structure of the floating net of the present invention, which is a "meter"-shaped net structure, with pull ropes on the edge, and the inside and frame materials of the floating net 2 are connected by swimming lane lines.

[0025] This embodiment adopts this floating net vortex elimination method, which is intended to be used in the water inlet of a diversion tunnel in a certain project. The water inlet section of the diversion tunnel used is a city gate type with a width of 2.80m and a height of 3.60m, wherein: the height of the straight wall 2.80m, 0.80m sag height, 857.50m elevation of the water inlet floor; followed by a 262.45m long city gate tunnel with a diameter of 2.80m×3.60m (width×height).

[0026] A kind of vortex elimination method for the floating net before the water inlet described in this embodiment, the specific steps are as follows:

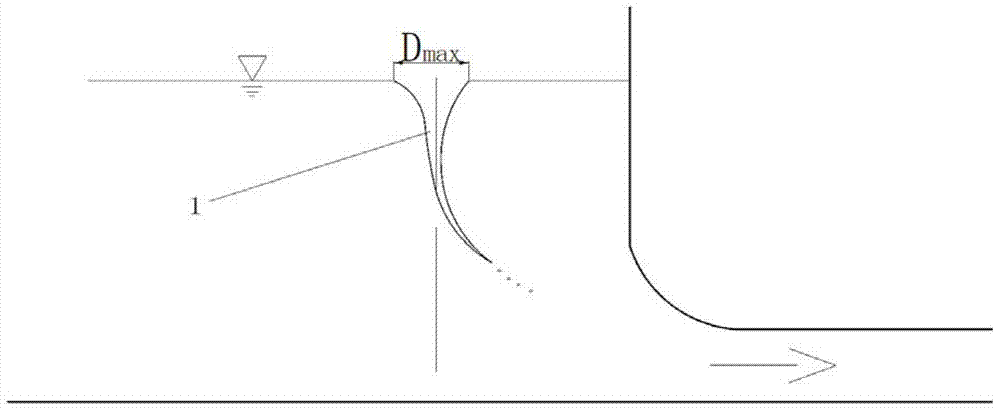

[0027] (1) The outdoor model test observation shows that when the water lev...

Embodiment 2

[0033] Another embodiment of the present invention is to replace the "meter" font floating net 2 with a regular hexagonal floating net, by the formula L=(3.0~5.0)D 涡max It can be calculated that the value range of the side length L of the floating net is 9.0cm~15.0cm, and the side length L=9.0cm of the floating net is taken in the present embodiment, wherein D 涡max is the maximum diameter of the vertical axis vortex, other operating steps and experimental conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com