Novel horizontal h-shaped pump gate device

A gate device, a new type of technology, is applied to pump devices, water supply devices, components of pumping devices for elastic fluids, etc. It can solve the problems of not having the function of self-flowing water, unfavorable unit equipment, unfavorable unit bearings, etc., to achieve Favorable ventilation and heat dissipation, operation and maintenance, improvement of water pump efficiency, and good energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

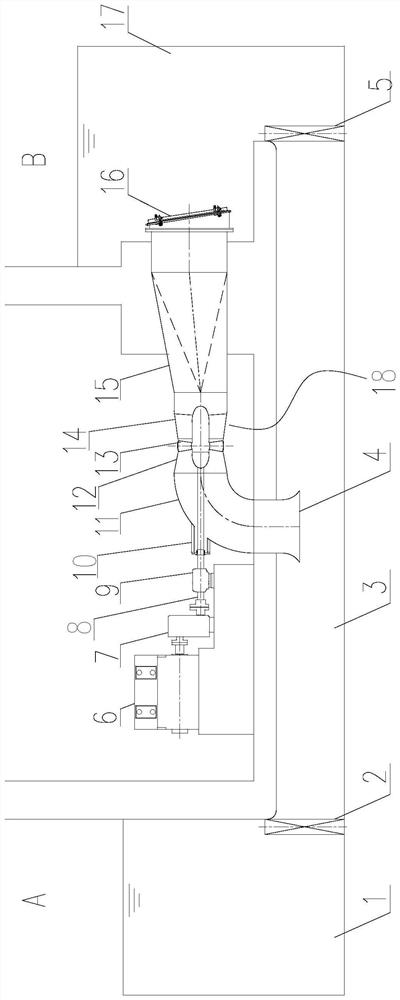

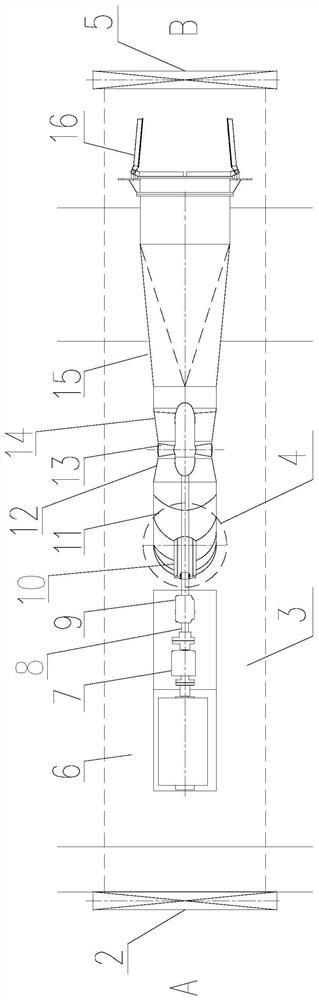

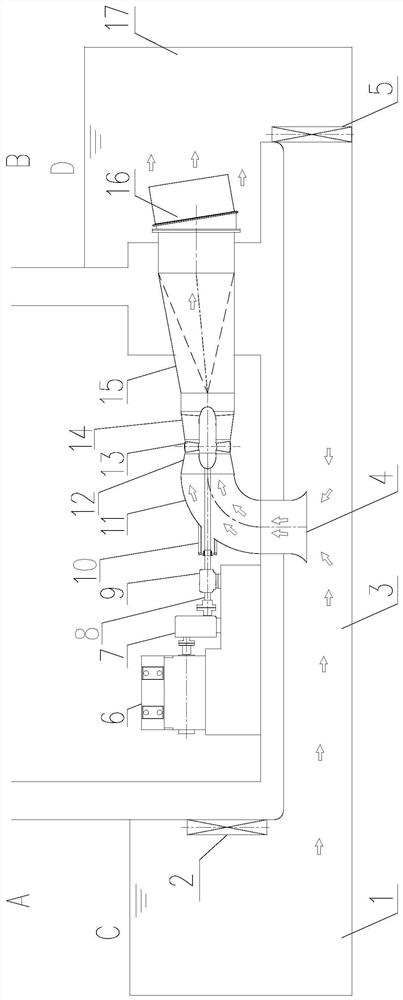

[0091] The new horizontal h-type pump gate device in this embodiment consists of a horizontal front shaft extension pump unit 18, a water suction trumpet pipe 4, a 90-degree elbow pipe 11, a diffuser pipe outlet flow channel 15, a lower water flow channel 3, a flap door 16 and Composed of working gate 5, horizontal front shaft extension pump unit 18 includes guide vane body 14, impeller chamber 12, impeller 13, pump shaft 8, packing seal 10, bearing box 9, gear reduction box 7 and asynchronous motor 6, and impeller 13 is arranged Between the guide vane body 14 and the packing seal 10, the pump shaft passes through the packing seal 10 from the 90-degree elbow 11, and the bearing box 9 is connected with the gear reduction box 7. The trumpet pipe 4 extends into the water flow channel 3 .

[0092] The impeller diameter D is 1m, the water pump diameter D N = 1.2m, 90-degree elbow turning radius R = 1.5m, water-absorbing horn tube diameter D 1 = 1.5m, water inlet to 90 degree elbo...

Embodiment 2

[0095] The new horizontal h-type pump gate device in this embodiment is the same as in Embodiment 1; the difference is that the diameter D of the impeller is 1.30m, and the diameter of the water pump is D N =1.4m, 90-degree elbow turning radius R=1.75m, water-absorbing trumpet pipe diameter D 1 = 1.95m, water inlet to 90-degree elbow water inlet h 1 = 1.58m, the width of the lower water channel d = 4.6m, the height of the lower water channel h 2 = 1.82m; the design net head of the pump is 0.88m, the net head range is 0-2.20m, the rated speed of the water pump is 225r / min, the gear reducer reduces the transmission, and the measured flow rate is 5m 3 / s, supporting asynchronous motor power 200kW; when the water level difference on both sides is 1m, the self-flowing drainage capacity of the lower flow channel is about 52m 3 / s.

Embodiment 3

[0097]The new horizontal h-type pump gate device in this embodiment is the same as in Embodiment 1; the difference is that the diameter D of the impeller is 1.5m, and the diameter of the water pump is D N =1.7m, 90-degree elbow turning radius R=1.7m, water-absorbing trumpet pipe diameter D 1 = 2.25m, water inlet to 90-degree elbow water inlet h 1 = 1.7m, the width of the lower water channel d = 5.4m, the height of the lower water channel h 2 =2.1m; the design net head of the pump is 0.86m, the net head range is 0~1.17m, the rated speed of the water pump is 180r / min, the gear reduction box reduces the transmission, and the measured flow rate is 6.25m 3 / s, supporting asynchronous motor power 250kW.

[0098] When the water level difference on both sides is 1m, the self-flowing drainage capacity of the lower flow channel is about 72.5m 3 / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com