Modular automatic water retaining device

An automatic blocking and modular technology, used in door/window protection devices, flood control panels, roads, etc., can solve the problems of troublesome transportation of automatic water blocking devices, difficult construction and installation, and increased construction costs, saving processing and The effect of construction period, transportation cost saving and maintenance cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

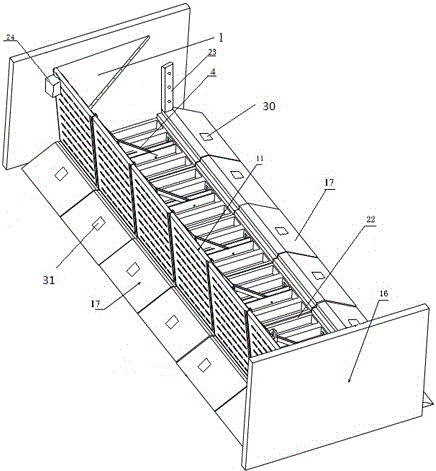

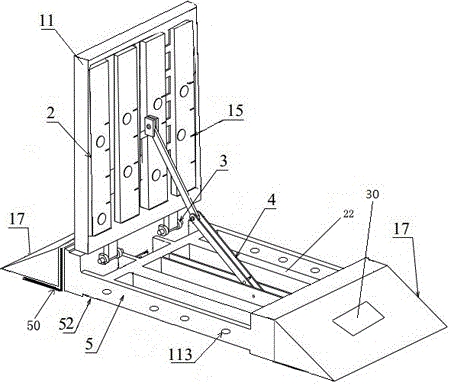

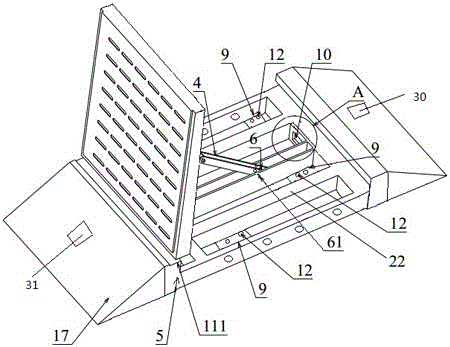

[0062] Such as figure 1 The modular automatic water retaining device shown is used to be fixed on the slope of the garage entrance and exit. The modular automatic water retaining device includes several automatic water retaining units arranged side by side. The automatic water retaining unit includes a base 5 And the panel 11, the base 5 is provided with more than two water storage chambers that run through the base up and down. The preferred number of water storage chambers in this embodiment is four, but it is not limited to only four. The water storage chambers are separated by beams 22 Separated, one end of the panel 11 is rotated on the base 5 through the hinge 3, and the panel 11 rotates to open and close the water storage chamber. The surface of the panel 11 that is used to cover the base 5 is provided with several floating plates 2, such as figure 2 , image 3 with Figure 4 As shown, on the base 5, the end that is different from the rotational connection between th...

Embodiment 2

[0082] The difference between this embodiment and Embodiment 1 is that the buffer slope 17 and the base 5 are an integrated mechanism, there is no second water inlet and second water outlet, but only the first water inlet and the first water outlet, and the first water inlet runs through the The gentle slope on the side where it is located, and the first water outlet runs through the buffer slope on the side where it is located.

Embodiment 3

[0084] Such as Figure 19 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment does not include buffer slopes 17 arranged on both sides of the base 5, and the rest of the structure is the same as Embodiment 1. When the height of the automatic water retaining device of the present invention is not When the automobile chassis and tires are damaged, the buffer slope 17 may not be provided. Generally when the height of the automatic water retaining device in the present application is less than four to five centimeters, the buffer slope 17 does not need to be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com