Integrated modularized LED lamp body

A technology of LED lamps and integrated modules, which is applied to semiconductor devices of light-emitting elements, lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as scattered connection and layout design, insufficient compact structure, and inconvenient maintenance and replacement. Achieve the effects of avoiding repeated disassembly and assembly, improving maintenance and assembly efficiency, and facilitating replacement and maintenance inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

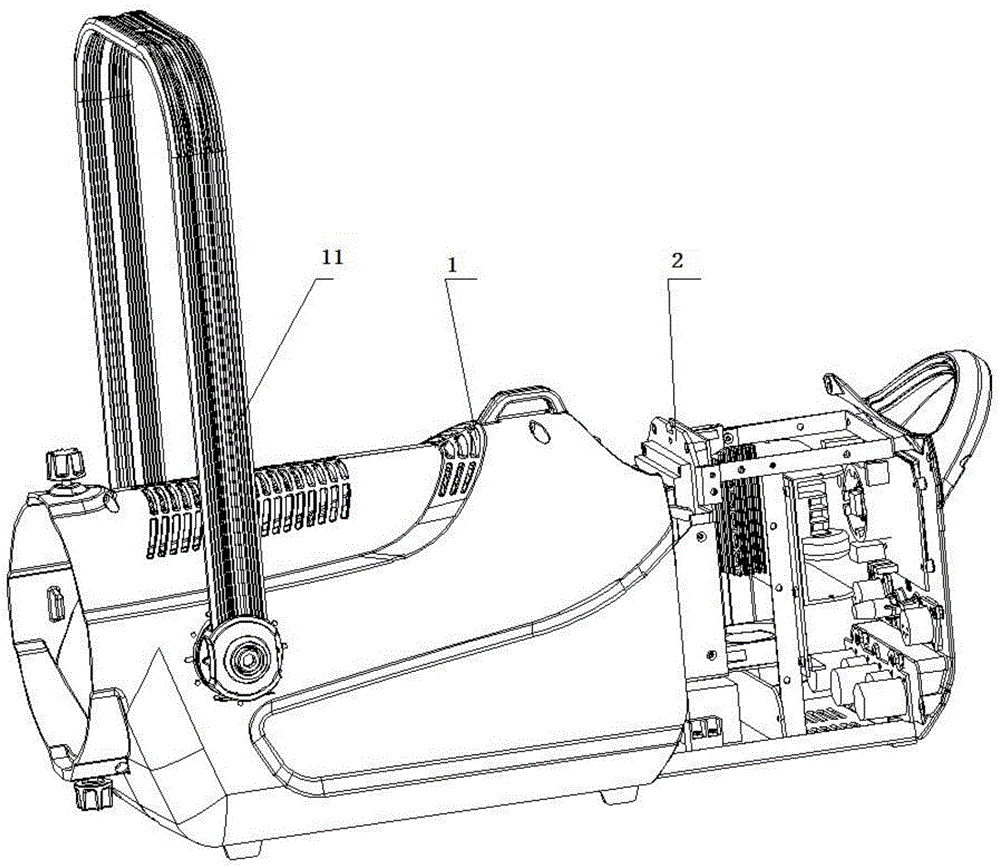

[0088] Such as Figure 1-5 As shown, this embodiment is an integrated modular LED lamp body, including:

[0089] Lamp body shell 1, lamp body module 2;

[0090] The lamp body housing 1 is composed of symmetrical left and right housings fixed symmetrically by screws. The lamp body housing 1 also includes a lamp body handle 11, and the lamp body handle 11 is fixedly connected with the lamp body housing 1 by screws.

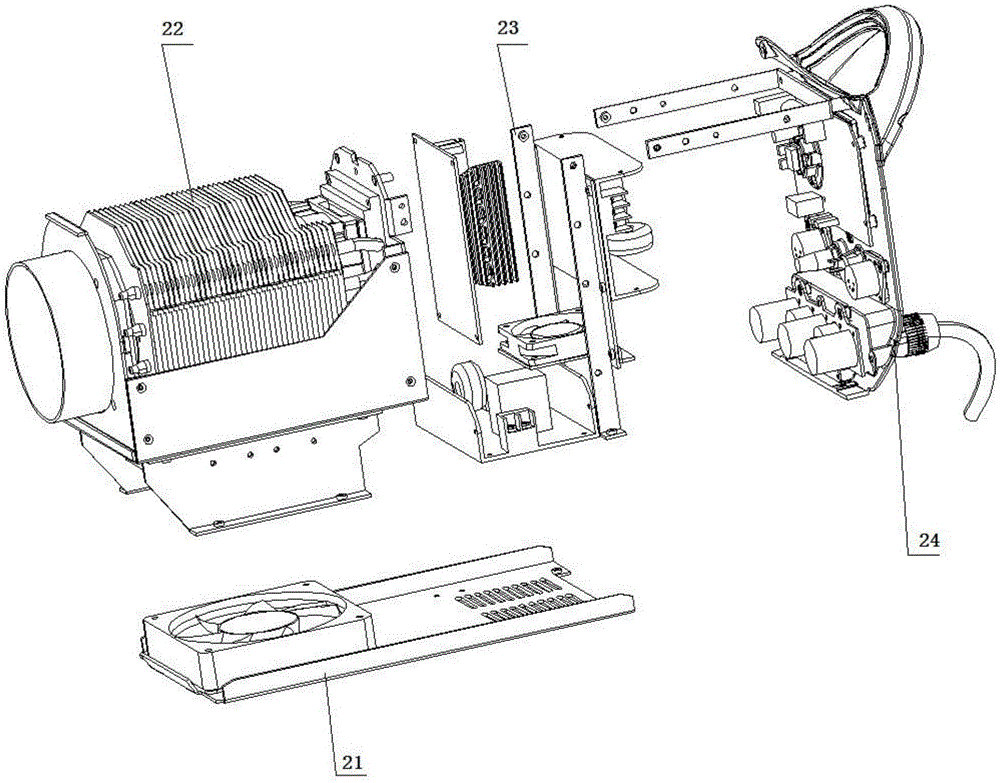

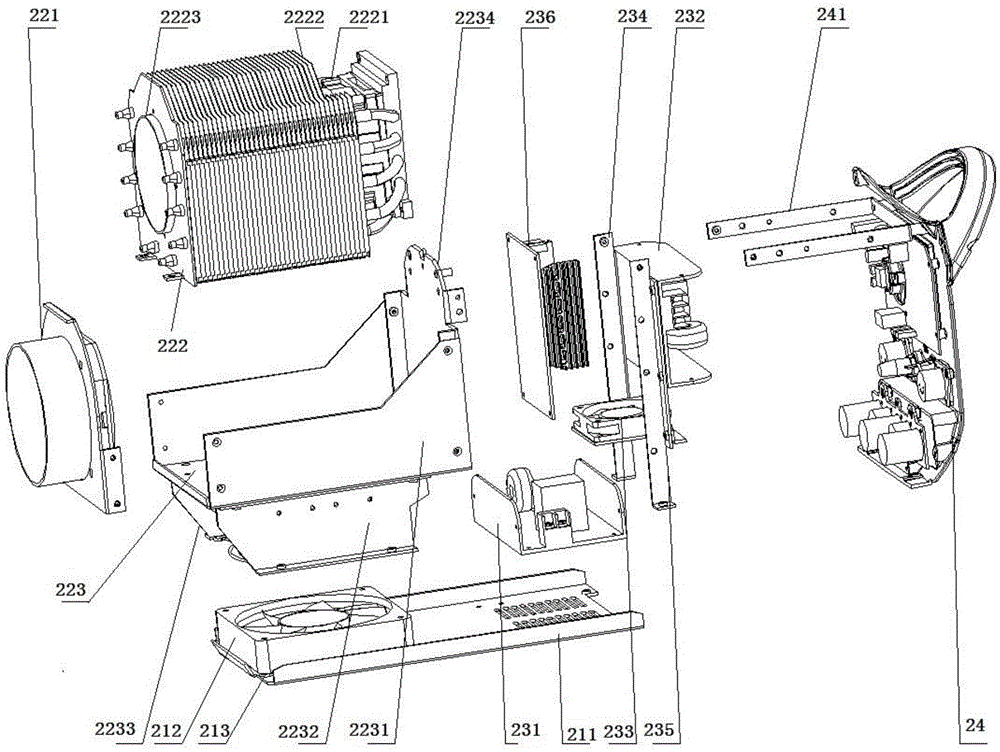

[0091] The lamp body module 2 includes a bottom substrate module 21; and a heat dissipation module 22, a power supply and drive combined heat dissipation module 23, and a mainboard module 24 installed on the bottom substrate module 21 sequentially from front to back;

[0092] The heat dissipation module 22 , the combined power supply and drive heat dissipation module 23 and the motherboard module 24 are connected in sequence.

[0093] The base plate module 21 includes a base plate 211, a fan one 212 and a fan spacer 213. A plurality of fixing holes are opened on t...

Embodiment 2

[0121] Such as Figure 6-7 As shown, the difference between this embodiment and embodiment 1 is that

[0122] The bracket module 223 also includes a wind deflector 2235 arranged above the fan one 212. The wind deflector 2235 includes two symmetrically arranged wind deflectors one 22351 and two wind deflectors 22352. The first wind deflector 22351 and the two wind deflectors The wind plate two 22352 is connected with the radiator support plate II2232 and the radiator support plate III2233 as a whole and is fixed below the radiator support plate I2231.

[0123] The air deflector 2235 has the following effects: 1) to prevent air leakage; 2) the wind blown by the fan-212 to the heat pipe radiator 2222 can be mixed evenly and blown to the air duct of the heat pipe radiator 2222; 3) the wind generated by the fan-212 passes through the air guide After the wind plate 2235, the uniform wind speed can reduce the noise.

[0124] Since the fan 1 212 is set under the heat dissipation mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com