A method and system for calibrating and detecting the hook position of a vertical shaft drilling rig

A detection system and detection method technology, applied in the direction of using mechanical devices, mechanical measuring devices, measuring devices, etc., can solve problems such as slippage uncertainty, accuracy cannot be guaranteed, complex structure, etc., to avoid potential risks, simple structure, Suitable for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with drawings and embodiments.

[0029] The invention provides a method for calibrating and detecting the hook position of a vertical shaft drilling rig, which includes the following steps:

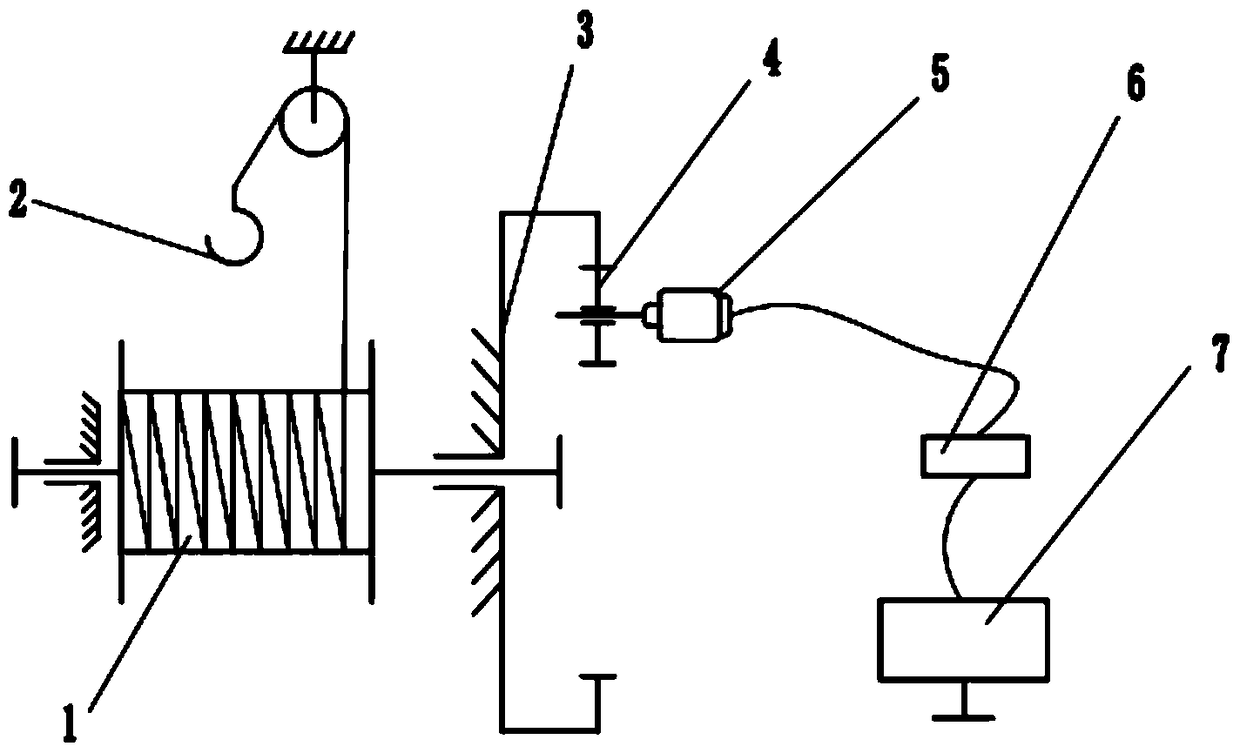

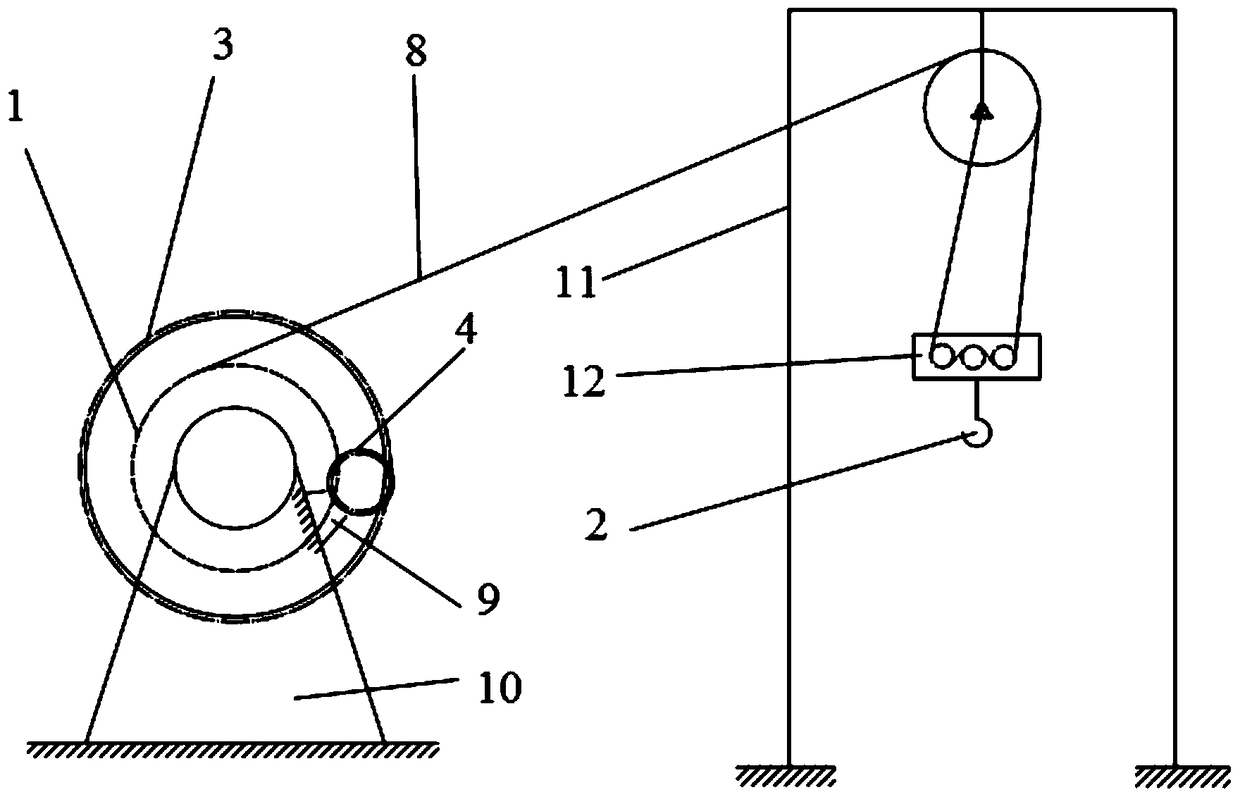

[0030] (1) Formulate the transmission gear that cooperates with the internal gear on one side of the drawworks of the vertical shaft drilling rig, and mesh the transmission gear with the internal gear on the one side of the drawworks through the gear fixing frame, so that the transmission gear and the internal gear on the one side of the drawworks have the same angular velocity;

[0031] (2) Connect the encoder to the transmission gear through the transmission shaft, and connect the encoder to the processing unit through the cable;

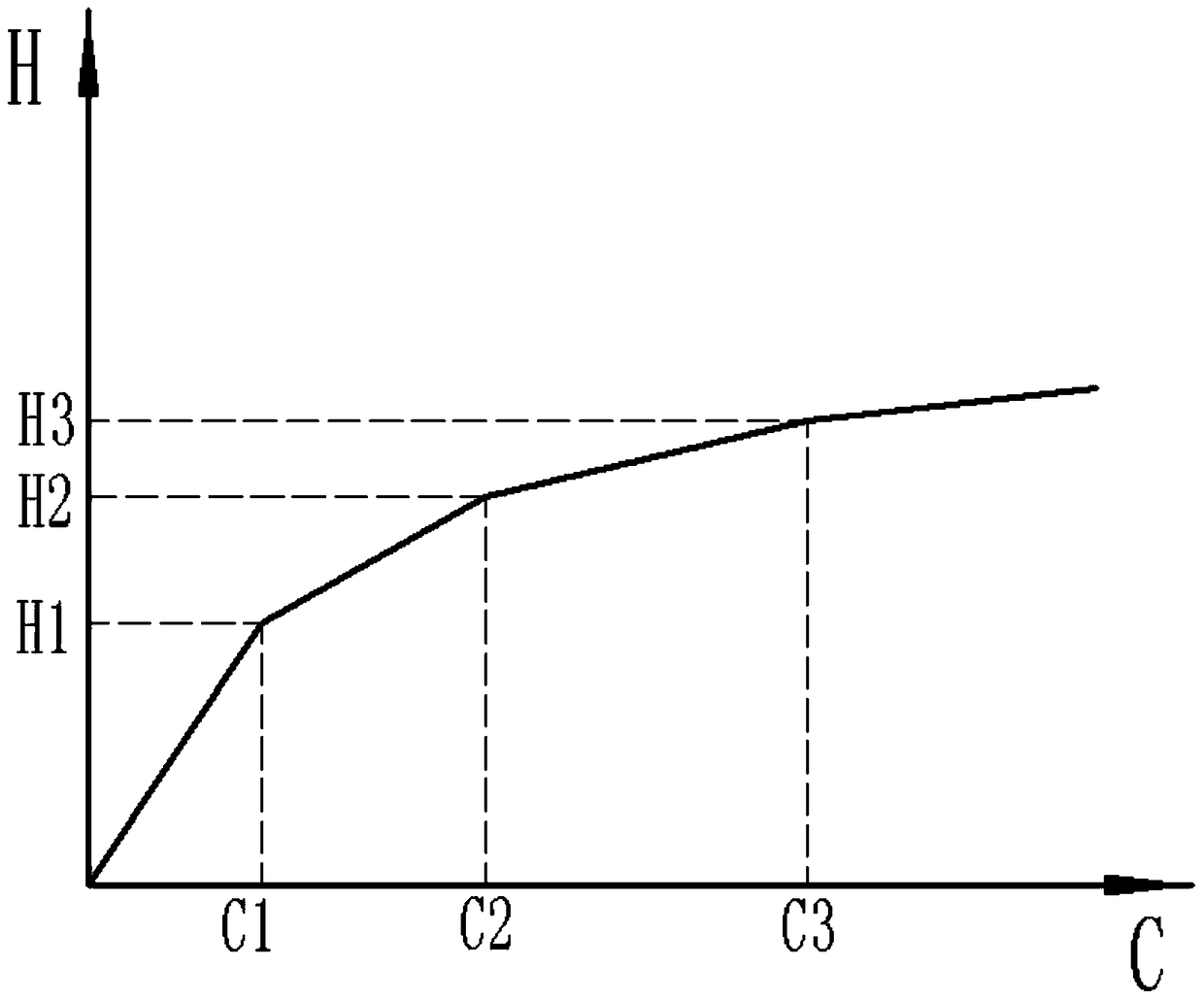

[0032] (3) Lower the hook to the zero position of the abutment, and record the current value C of the absolute encoder 0 , marking the current height H 0 is 0.00m;

[0033] (4) Lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com