Two-dimensional thermal wind speed and direction sensor based on ceramic package and its manufacturing method

A technology of wind speed and direction, ceramic packaging, applied in the direction of using thermal variables to measure fluid velocity, instruments, measuring devices, etc., can solve the problems of high power consumption, poor device consistency, low thermal response, etc., to ensure the processing accuracy and Consistency, ensuring symmetry and consistency, reducing the effect of lateral heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

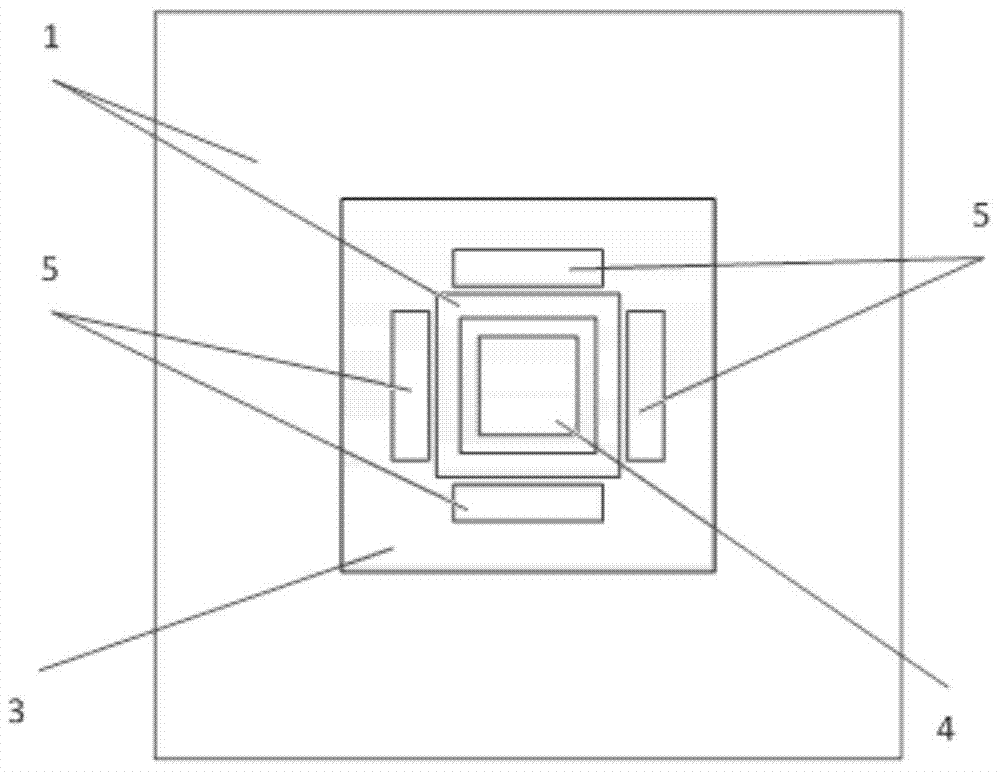

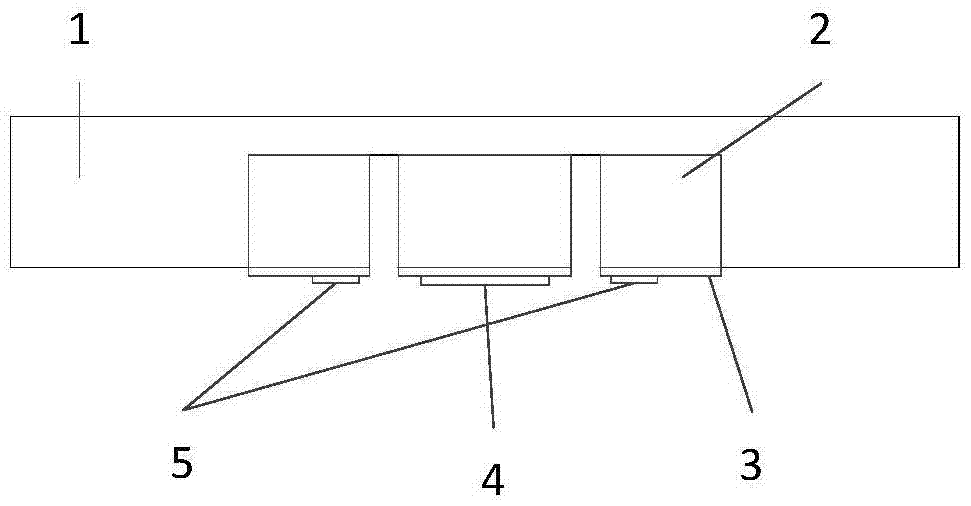

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The two-dimensional thermal wind speed and direction sensor based on ceramic packaging provided by the present invention uses a low-temperature co-fired ceramic process to manufacture a ceramic-silicon substrate, and embeds a silicon material layer into the ceramic, which significantly reduces the thickness of the packaged ceramic on the silicon sensor chip. , which reduces the lateral heat conduction of the sensor; at the same time, the heating and temperature measuring elements are set on the silicon material layer to ensure the consistency of the manufacturing of the heating and temperature measuring elements; in addition, there is a heat insulation groove between the heating and temperature measuring elements , which further reduces the lateral heat conduction between the heating element and the temperature measuring element, and reduces the power consumption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com