Color-changing indicating device and transparent ink

A color change indicator, transparent ink technology, applied in ink, material analysis by observing the impact on chemical indicators, household appliances, etc., can solve problems such as failure, non-neutrality, and deviation of the indication effect of the indicator device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

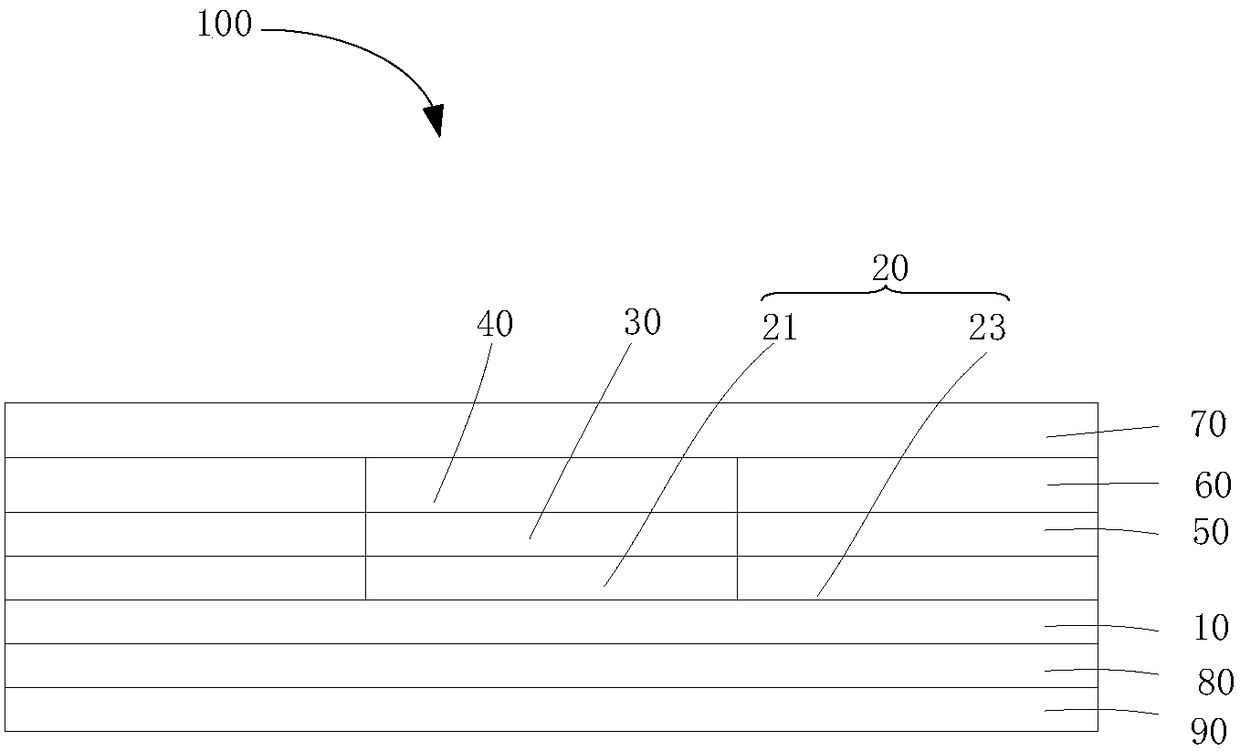

[0063] The structure of the color change indicating device of embodiment 1 is as follows figure 1 As shown, it includes a base layer 10 , an indicator layer 20 , a protective layer 30 , an isolation layer 40 , a release layer 50 , a first adhesive layer 60 , a barrier layer 70 , a second adhesive layer 80 and a release layer 90 .

[0064] Wherein, the material of the base layer 10 is PET, and the thickness is 0.1mm; the material of the indicating layer 20, the protective layer 30, and the isolation layer 40 is polyvinyl butyral, and the thickness is 0.1mm; the material of the release layer 50 is silicone oil, The thickness is 0.005 mm; the material of the first adhesive layer 60 is acrylic resin, and the thickness is 0.05 mm; the material of the barrier layer 70 is PVC, and the thickness is 0.15 mm; the material of the second adhesive layer 80 is acrylic resin, and the thickness is 0.1 mm. mm; the material of the peeling layer 90 is cellophane with a thickness of 0.15mm.

[0...

Embodiment 2

[0070] The structure of the color change indicating device of embodiment 2 is as follows figure 1 As shown, it includes a base layer 10 , an indicator layer 20 , a protective layer 30 , an isolation layer 40 , a release layer 50 , a first adhesive layer 60 , a barrier layer 70 , a second adhesive layer 80 and a release layer 90 .

[0071] Among them, the material of the base layer 10 is PVC with a thickness of 0.15 mm; the material of the indicating layer 20, the protective layer 30 and the isolation layer 40 is hydroxyethyl cellulose with a thickness of 0.08 mm; the material of the release layer 50 is polyvinyl alcohol , with a thickness of 0.05mm; the material of the first adhesive layer 60 is polyurethane, with a thickness of 0.1mm; the material of the barrier layer 70 is PET, with a thickness of 0.1mm; the material of the second adhesive layer 80 is polyurethane, with a thickness of 0.08mm ; The material of the release layer 90 is release paper with a thickness of 0.10 mm....

Embodiment 3

[0077] The structure of the color change indicating device of embodiment 3 is as follows figure 1 As shown, it includes a base layer 10 , an indicator layer 20 , a protective layer 30 , an isolation layer 40 , a release layer 50 , a first adhesive layer 60 , a barrier layer 70 , a second adhesive layer 80 and a release layer 90 .

[0078] Wherein, the base layer 10 is made of PET with a thickness of 0.2 mm; the material of the indicating layer 20, the protective layer 30 and the isolation layer 40 is hydroxypropyl cellulose with a thickness of 0.05 mm; the material of the release layer 50 is emulsified paraffin, The thickness is 0.05mm; the material of the first adhesive layer 60 is acrylic resin, and the thickness is 0.05mm; the material of the barrier layer 70 is PET, and the thickness is 0.07mm; the material of the second adhesive layer 80 is polyurethane, and the thickness is 0.03mm ; The material of the release layer 90 is paper coated with silicone oil, with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com