A method for detecting expansion rate of oil well cement

A technology for oil well cement and detection methods, applied in the direction of material thermal expansion coefficient, etc., can solve problems such as unreasonable structural design, high material cost, production safety accidents, etc., to improve measurement accuracy and accuracy, reduce test data errors, and guarantee The effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for detecting the expansion rate of oil well cement, comprising a pulping step, a mold loading step, and a maintenance and demoulding step, and also includes an initial measurement step, an age measurement step, and an expansion rate calculation step. The pulping step refers to a stirring cup Put it on the base of the agitator, mix the slurry with a water-cement ratio of 0.44, and stir evenly to obtain the slurry; the mold loading step refers to pouring the cement slurry into the test mold and mixing it evenly, and scraping off the upper part of the test mold with a scraper Excessive mud is covered with a test mold cover plate; the maintenance and demoulding step refers to putting the trial mold in the curing box, and demoulding after curing to obtain a cement test block; the initial measurement step refers to putting the mold after demoulding Mark the direction of the cement test block, and then put it into the measuring device that has been calibrated to zero,...

Embodiment 2

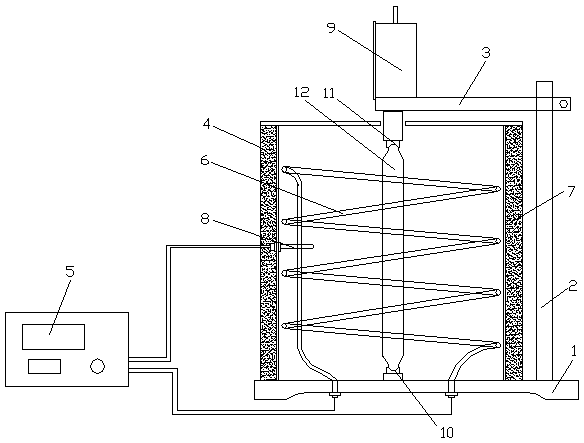

[0038] see figure 1 , a method for detecting the expansion rate of oil well cement, comprising a pulping step, a mold loading step, and a maintenance and demoulding step, and also includes an initial measurement step, an age measurement step, and an expansion rate calculation step, and the slurrying step refers to stirring The cup is placed on the base of the agitator, and the slurry is mixed with a water-cement ratio of 0.44, and the slurry is evenly stirred; the mold loading step refers to pouring the cement slurry into the test mold and mixing it evenly, and scraping off the test mold with a scraper. The excessive mud on the upper part is covered with a test mold cover plate; the curing and demoulding step refers to putting the trial mold in the curing box, and demoulding after curing to obtain a cement test block; the initial measurement step refers to putting the demoulding The direction of the final cement test block is marked, and then placed in the measuring device tha...

Embodiment 3

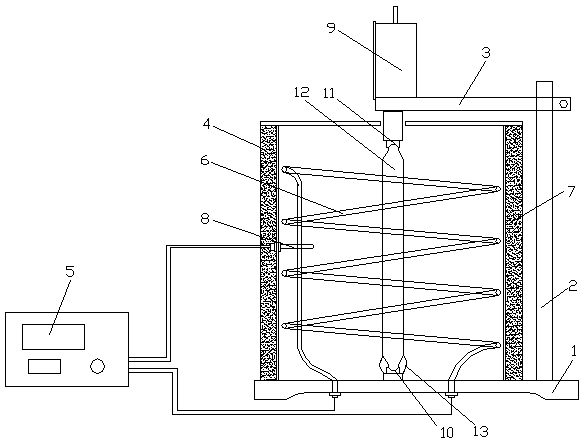

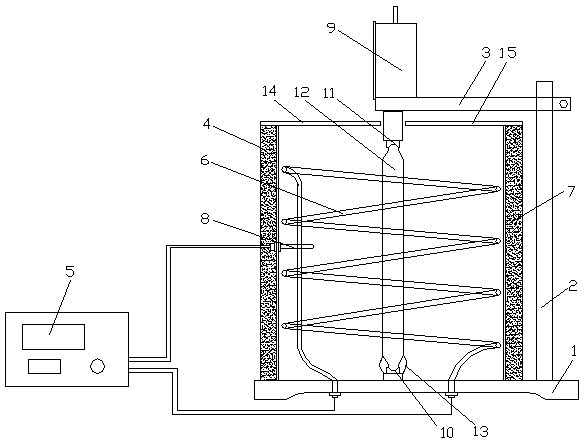

[0046] see figure 2 , a method for detecting the expansion rate of oil well cement, comprising a pulping step, a mold loading step, and a maintenance and demoulding step, and also includes an initial measurement step, an age measurement step, and an expansion rate calculation step, and the slurrying step refers to stirring The cup is placed on the base of the agitator, and the slurry is mixed with a water-cement ratio of 0.44, and the slurry is evenly stirred; the mold loading step refers to pouring the cement slurry into the test mold and mixing it evenly, and scraping off the test mold with a scraper. The excessive mud on the upper part is covered with a test mold cover plate; the curing and demoulding step refers to putting the trial mold in the curing box, and demoulding after curing to obtain a cement test block; the initial measurement step refers to putting the demoulding The direction of the final cement test block is marked, and then placed in the measuring device th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com