Polarizing plate and liquid crystal display device

A technology for polarizers and polarizers, applied in the fields of polarizers and liquid crystal display devices, can solve the problems of reduced display quality, uneven display, light leakage, etc., and achieve the effect of suppressing uneven display and excellent display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

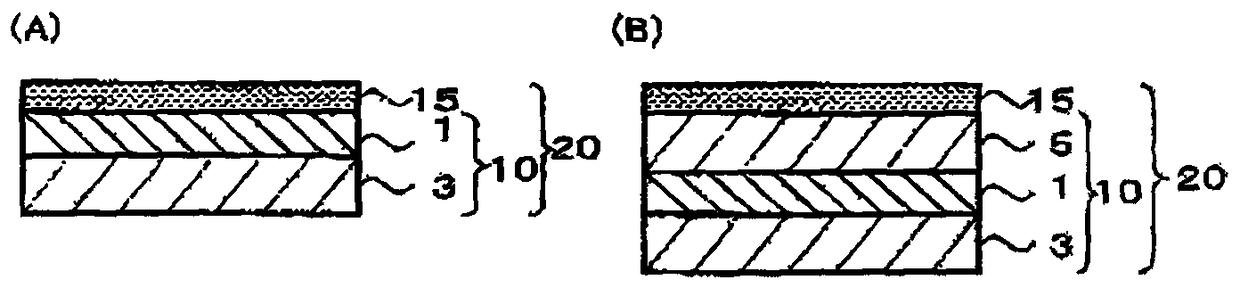

Image

Examples

Embodiment 1

[0109] (production of polarizer)

[0110]A polyvinyl alcohol film with a thickness of 20 μm (the average degree of polymerization is about 2400, and the degree of saponification is 99.9 mol%) is uniaxially stretched 5 times by dry stretching, and then, while maintaining the stretched state, the film is heated at 60°C. After immersing for 1 minute in pure water of iodine / potassium iodide / water with a weight ratio of iodine / potassium iodide / water of 0.05 / 5 / 100 in an aqueous solution at 28° C. for 60 seconds. Thereafter, it was immersed in an aqueous solution having a weight ratio of potassium iodide / boric acid / water of 8.5 / 8.5 / 100 at 72° C. for 300 seconds. Next, it was washed with pure water at 26° C. for 20 seconds, and then dried at 65° C. to obtain an absorption-type polarizing film having a thickness of 7 μm in which iodine was adsorbed and oriented on the polyvinyl alcohol film.

[0111] Next, a water-based adhesive (which is obtained by dissolving 3 parts of carboxy-modi...

Embodiment 2

[0114] On the triacetyl cellulose film (first protective film) of the polarizing plate obtained in Example 1, a commercially available acrylic adhesive sheet with an adhesive layer thickness of 5 μm was laminated, and the A reflective polarizing film with a thickness of 26 μm (trade name “Advanced Polarized Film, Version 3 (APF-V3)” purchased from 3M Company) was used as the first protective film. Except having used the said laminated body as a polarizing plate, the water contact angle and dimensional change rate were measured similarly to Example 1, and the visual recognition test of display unevenness was performed.

Embodiment 3

[0116] A polyvinyl alcohol film with a thickness of 30 μm (average degree of polymerization is about 2400, saponification degree is 99.9 mol % or more) is uniaxially stretched about 5 times by dry stretching, and then under the condition of maintaining tension, the polyvinyl alcohol film is stretched at 60 After immersing in pure water at °C for 1 minute, it was immersed in an aqueous solution having a weight ratio of iodine / potassium iodide / water of 0.05 / 5 / 100 at 28°C for 60 seconds. Thereafter, it was immersed in an aqueous solution having a weight ratio of potassium iodide / boric acid / water of 8.5 / 8.5 / 100 at 72° C. for 300 seconds. Next, it was washed with pure water at 26° C. for 20 seconds, and then dried at 65° C. to obtain an absorption-type polarizing film having a thickness of 12 μm in which iodine was adsorbed and oriented on the polyvinyl alcohol film.

[0117] A triacetyl cellulose film [trade name "KC2UAW" purchased from KONICA MINOLTA Co., Ltd.] with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com