High-voltage integrated control system for electric car

A high-voltage integration and control system technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve problems such as increasing the length of the cooling system pipeline, difficulty in space layout, and increasing pipeline loss, and achieves a high level of improvement. Heat dissipation efficiency, cost reduction, effect of reducing connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

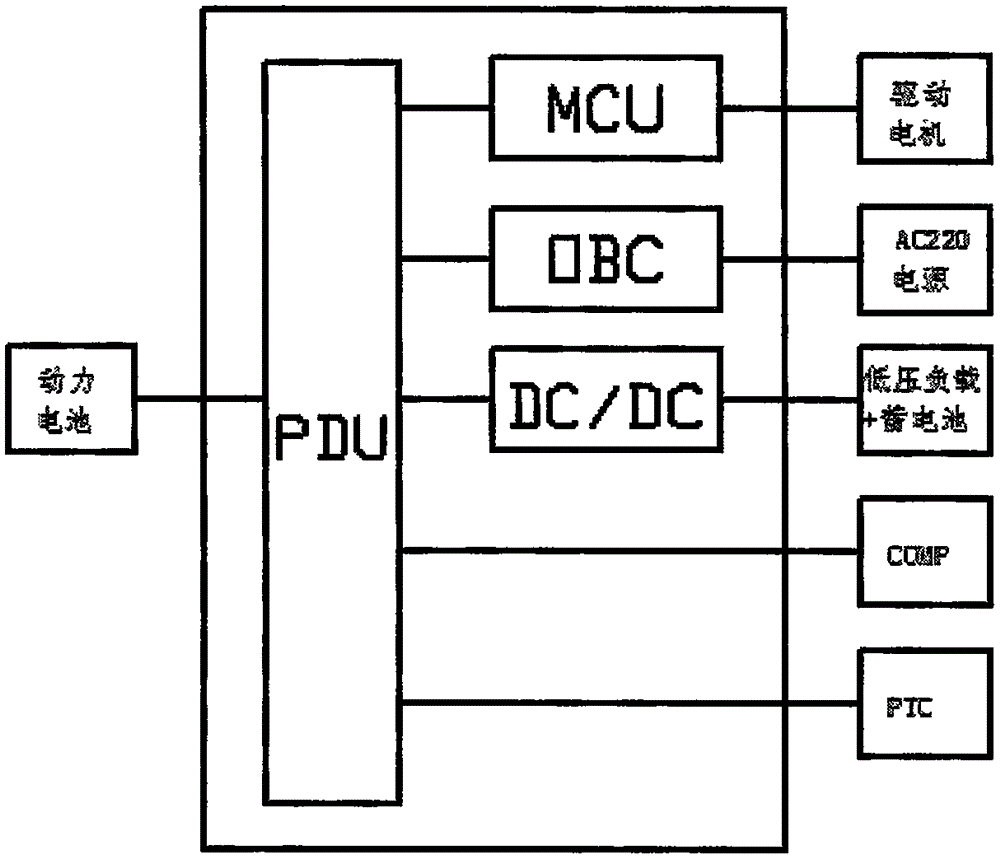

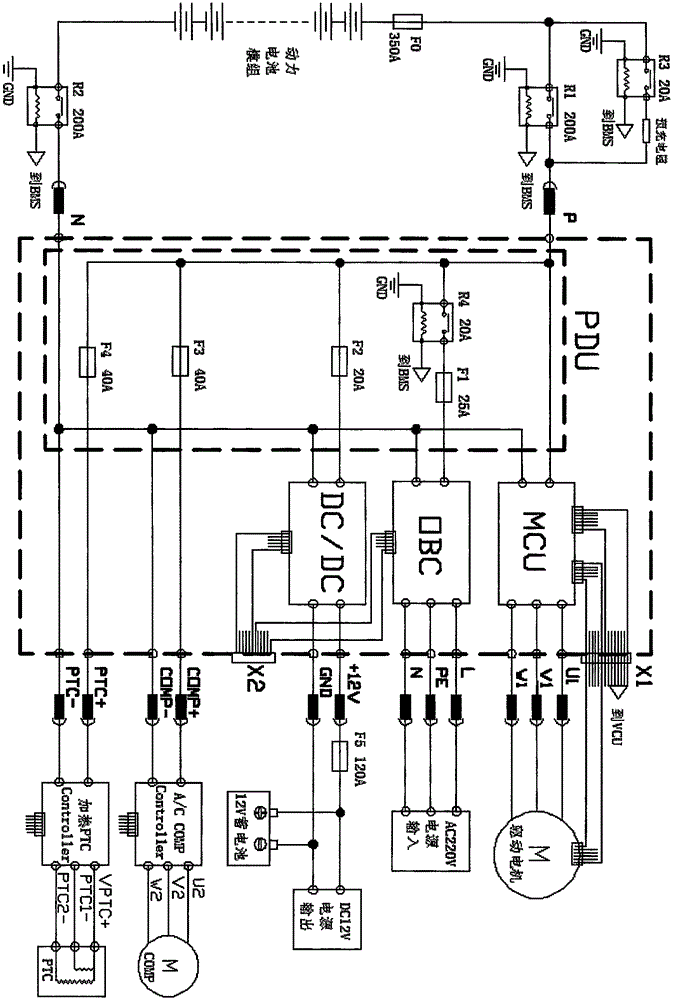

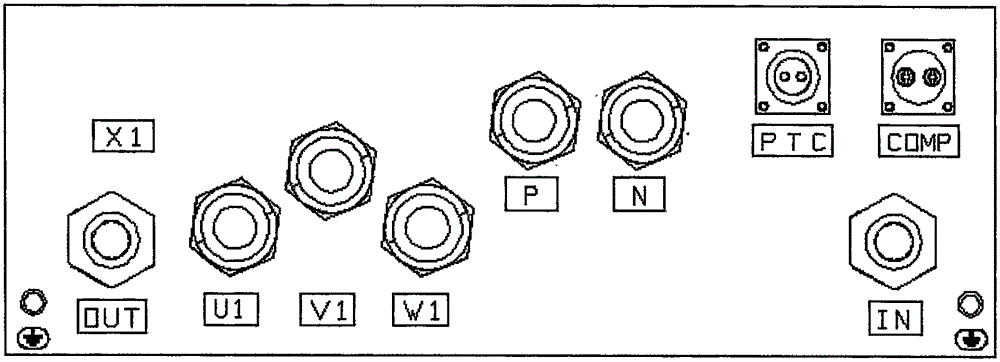

[0025] Such as Figure 1-4 As shown, the electric vehicle high-voltage integrated control system of this embodiment includes: a high-voltage power distribution unit, a drive motor controller, an on-board charger and a DC step-down converter; it is characterized in that: the high-voltage power distribution unit is respectively connected to the A drive motor controller, an on-board charger, and a DC step-down converter, the high-voltage power distribution unit, the drive motor controller, an on-board charger, and a DC step-down converter are integrated in a box with a radiator; and the box The outer surface of the body is provided with an X1 communication interface connected to the drive motor controller, and an X2 communication interface connected to the vehicle charger, DC step-down converter and high-voltage power distribution unit. The drive motor controller is connected to the high-voltage drive motor through a three-phase AC power line, the vehicle charger is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com