Low temperature plane target and installation method thereof

A planar target and low-temperature technology, applied in low-temperature fusion reactors, greenhouse gas reduction, nuclear reactors, etc., can solve the problems of difficult processing and assembly, high precision requirements, complex design, etc., and achieve low manufacturing costs, simple overall structure, installation and operation Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

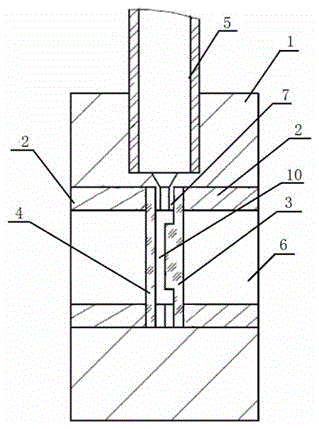

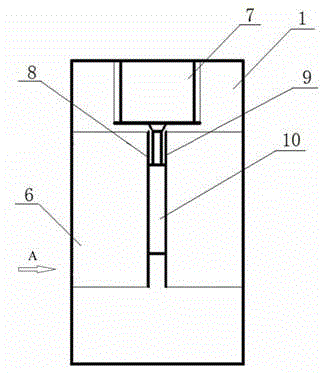

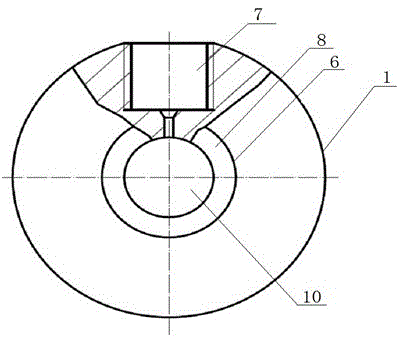

[0025] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the low-temperature planar target of this embodiment includes a target core 1, a spacer 2, a detection window 3, an incident window 4 and an air-filled tube 5. The target core 1 is provided with a circular hole 6, and the circular hole 6 is connected to the target. The core 1 is coaxially arranged, and a connecting hole 7 is arranged on the side wall of the target core 1, and the connecting hole 7 communicates with the round hole 6, and the gas-filled tube 5 is connected with the connecting hole 7, and a round hole 7 is arranged on the inner wall of the round hole 6. The annular left side wall 8 and the annular right side wall 9, the annular left side wall 8 and the annular right side wall 9 are all perpendicular to the inner wall of the circular hole, the incident window 4, the detection window 3, An accommodating cavity 10 is formed between the circular left side wall 8 and the circular right side wal...

Embodiment 2

[0032] Such as figure 1 , figure 2 , image 3 with Figure 5 As shown, the low-temperature planar target of this embodiment includes a target core 1, a spacer 2, a detection window 3, an incident window 4 and an air-filled tube 5. The target core 1 is provided with a circular hole 6, and the circular hole 6 is connected to the target. The core 1 is coaxially arranged, and a connecting hole 7 is arranged on the side wall of the target core 1, and the connecting hole 7 communicates with the round hole 6, and the gas-filled tube 5 is connected with the connecting hole 7, and a round hole 7 is arranged on the inner wall of the round hole 6. The annular left side wall 8 and the annular right side wall 9, the annular left side wall 8 and the annular right side wall 9 are all perpendicular to the inner wall of the circular hole, the incident window 4, the detection window 3, An accommodating cavity 10 is formed between the circular left side wall 8 and the circular right side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com