Test method for ion implantation machine base

An ion implanter and ion implantation technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., to achieve simple operation, accurate results, and stable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

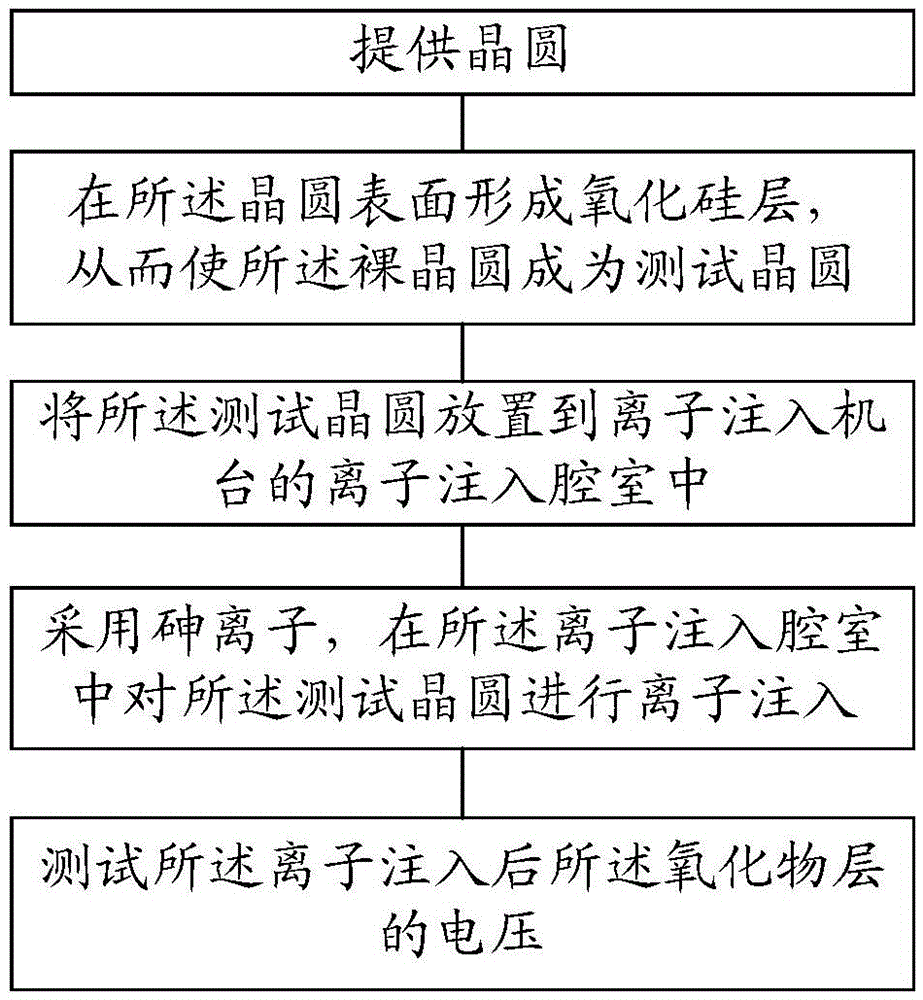

[0028] For the equipment of the ion implantation process, the abnormal conditions of the equipment will affect the growth effect of the oxide layer on the polysilicon surface. If the corresponding product is produced in a poor condition of the chamber of the machine, it will affect the growth of the subsequent oxide layer and affect the electrical characteristics of the final device. Therefore, it is very important to monitor the condition of the chamber during the ion implantation process. However, there is currently no effective method to monitor the effect of ion implantation on the thickness of the subsequently grown oxide layer on the polysilicon surface.

[0029] For this reason, the present invention provides a new test method for ion implantation equipment to directly monitor the growth and production status of the oxide layer of polysilicon after ion implantation.

[0030] In order to make the above objects, features and advantages of the present invention more compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com