Processing method for printing circuit board semi-PTH groove

A technology for printed circuit boards and processing methods, applied in the directions of printed circuits, printed circuit manufacturing, and the formation of electrical connection of printed components, can solve problems such as labor costs, poor adhesion between copper plating and the inner wall of the tank, and product scrapping, etc. Improve product quality, eliminate copper peeling, and eliminate the effect of copper coiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

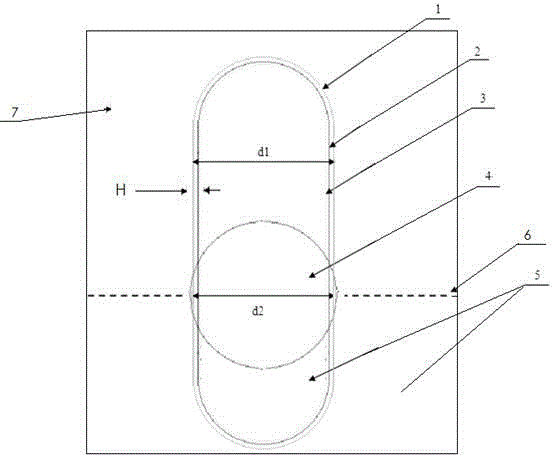

[0015] Embodiment, with reference to accompanying drawing, a kind of processing method of printed wiring board half PTH groove is characterized in that taking the following steps:

[0016] a. Determine the position of the half PTH slot on the circuit board 7, and design a cutting line 6 at the end of the half slot according to the size of the half PTH slot on the board, and form a slot by continuous drilling with a drill needle or milling with a milling cutter. A slot with width d1;

[0017] b. Copper plating is carried out on the inner wall of the tank, the thickness of the copper layer in the copper plating area 2 is H, H=0.018~0.075mm;

[0018] c. Tin-plate the PTH tank, and coat a layer of tin-plated protective film 3 on the outside of the copper layer in the copper-plated area 2. The thickness of the tin layer is adjusted according to the width of the slot hole and the thickness of copper plating, which is between 0.08 and 0.20mm ;

[0019] d. Find the center O of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com