Tobacco redrying intelligent automatic placing device

An automatic technology for re-curing tobacco leaves, which is applied to tobacco, prepared tobacco, claw arms, etc., can solve the problems of insufficient intelligence and cannot fully satisfy the automatic swinging of re-cured tobacco leaves, so as to improve production efficiency, prevent occupational disease risks, and reduce The effect of worker labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

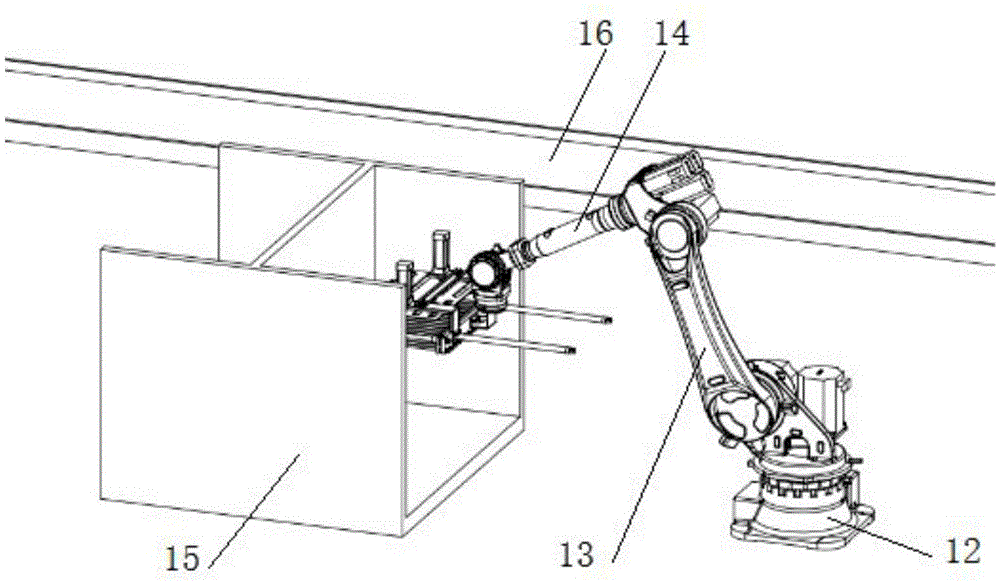

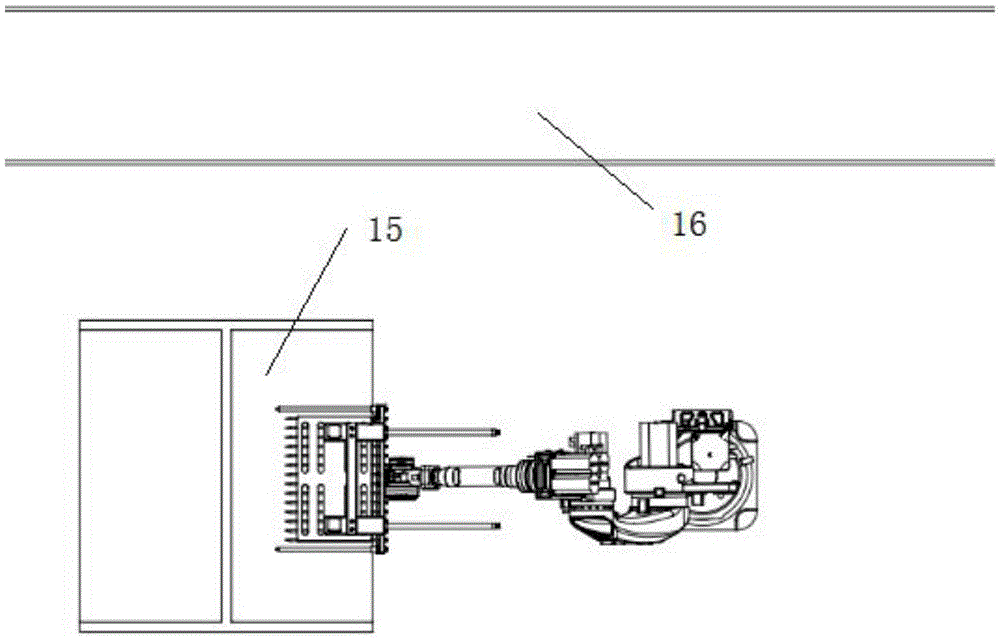

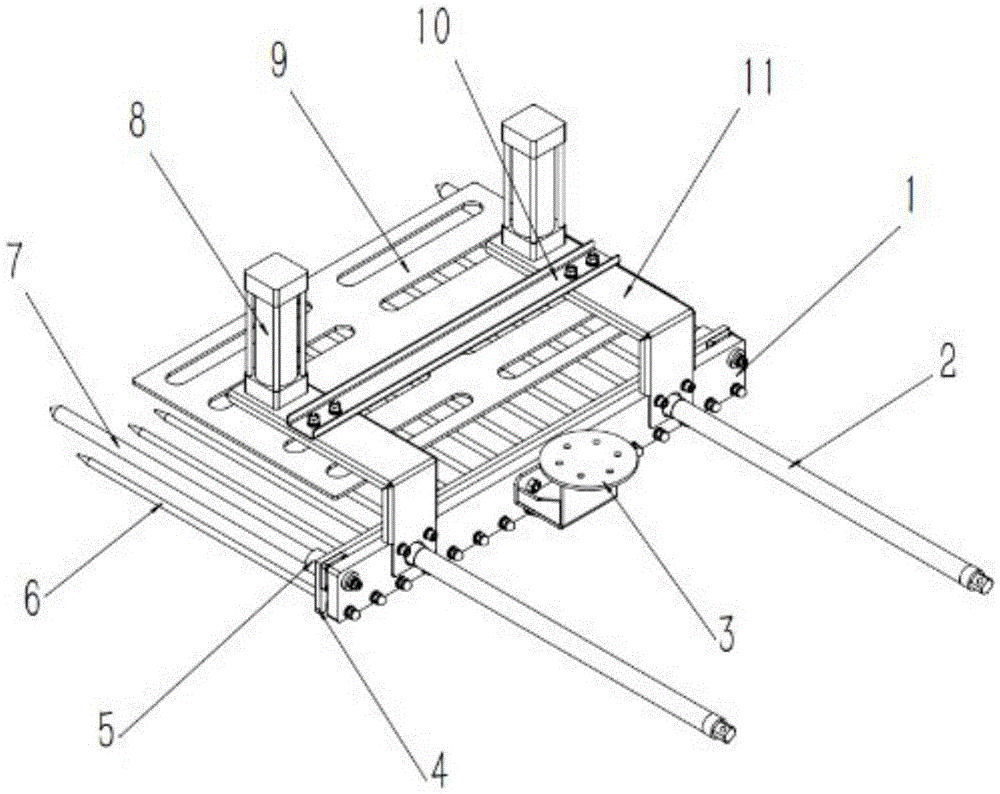

[0040]Under the initial state, the horizontal material pushing cylinder 2 and the vertical material pressing cylinder 8 are in the contracted state, and the quantitative tobacco leaf frame 15 is placed next to the device. Subsequent shoveling, start the whole set of devices, the system starts self-inspection, after the self-inspection is completed, turn on the motor, start the horizontal production line 16 at the same time, let the belt of the horizontal production line 16 start to rotate; the motor controls the robot body, rotates to the direction facing the tobacco leaf frame 15, passes through a The rotation of the primary mechanical arm 13 and the secondary mechanical arm 14 adjusts the shovel bar 6 to the set height, then the primary mechanical arm 13 rotates forward, and the secondary mechanical arm 14 rotates forward to scoop up the tobacco leaves in the tobacco leaf frame 15 , the vertical pressing cylinder 8 stretches out to compress the tobacco leaves; the first-level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com