A vertical flat die pellet machine

A granulator and flat die technology, applied in the direction of mold extrusion granulation, press, material forming press, etc., can solve the problems of insufficient granule compactness, insufficient pressure, large friction, etc., to achieve sufficient pressure and advanced The effect of fast material speed and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

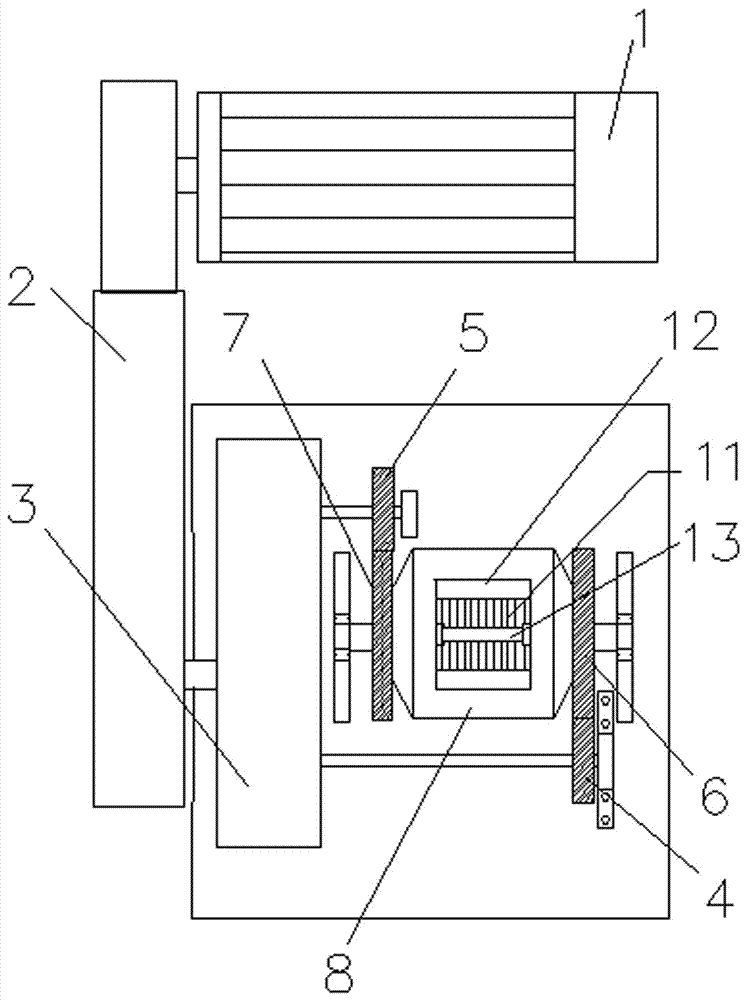

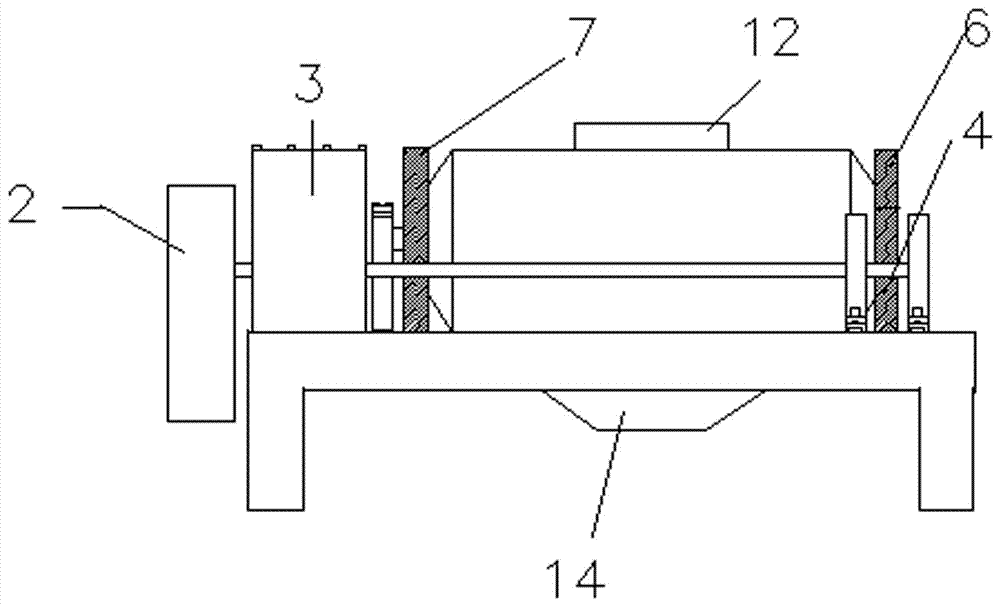

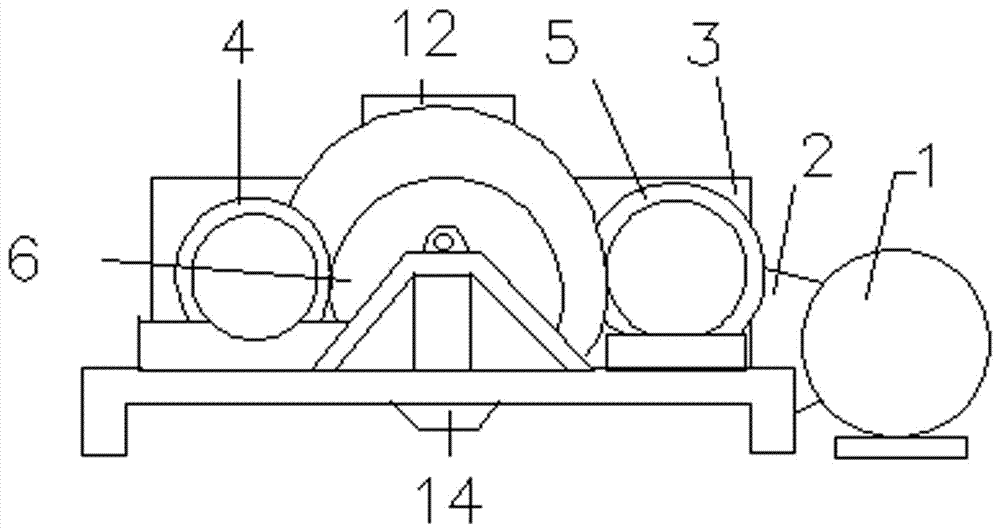

[0038] The vertical flat die granulator includes a motor 1, a motor transmission device 2, a gearbox 3, a front power gear 4, a rear power gear 5, No. 1 main transmission gear, No. 2 main transmission gear 7, and a granulation chamber 8 , No. 1 flat die 9, No. 2 flat die 10, pressure roller 11, material inlet 12, partition 13 and discharge hopper 14, each component is connected in the following manner, motor 1 is connected with motor transmission device 2, and motor transmission device 2 Connected with the gearbox 3, the front power gear 4 is connected to the gearbox 3 through the power shaft, the front power gear 4 is closely meshed with the No. 1 main drive gear 6, and the No. 1 main drive gear 6 and the No. On the main shaft, installed on both sides of the granulation chamber 8, the No. 1 main transmission gear 6 and the No. 2 main transmission gear 7 are respectively connected with the No. 1 flat die 9 and the No. 2 flat die 10, and pressure rollers 11 are respectively inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com