Control method for electron beam welding splash of part with narrow lock bottom structure

A technology for electron beam welding and structural parts, applied in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of welding spatter, affecting the use of the engine, and difficulty in the electron beam welding process, and achieve the effect of improving the technical level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

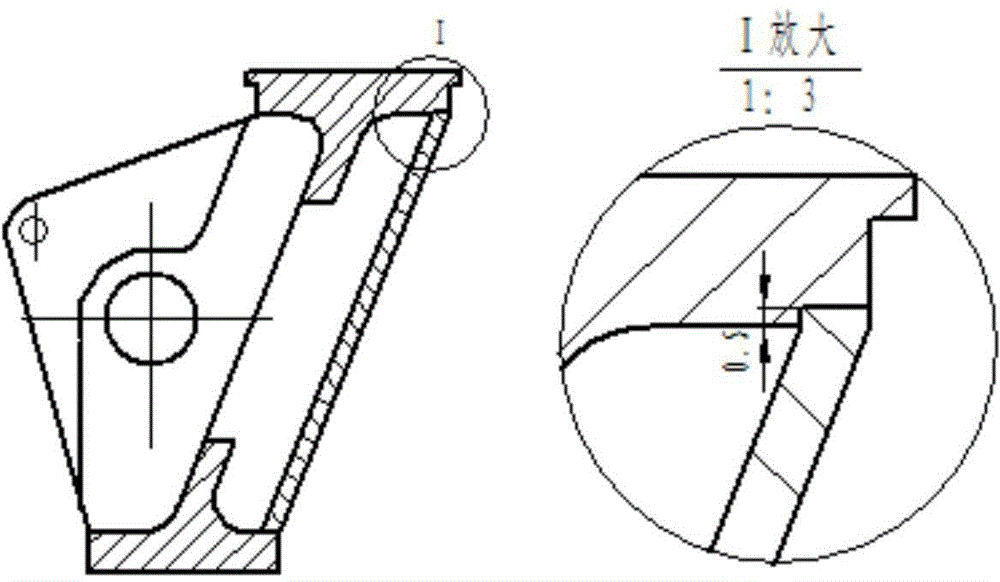

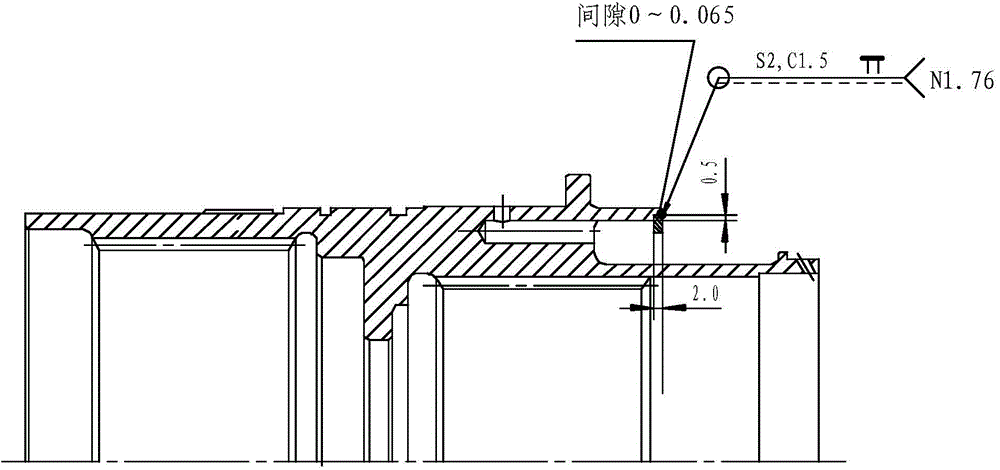

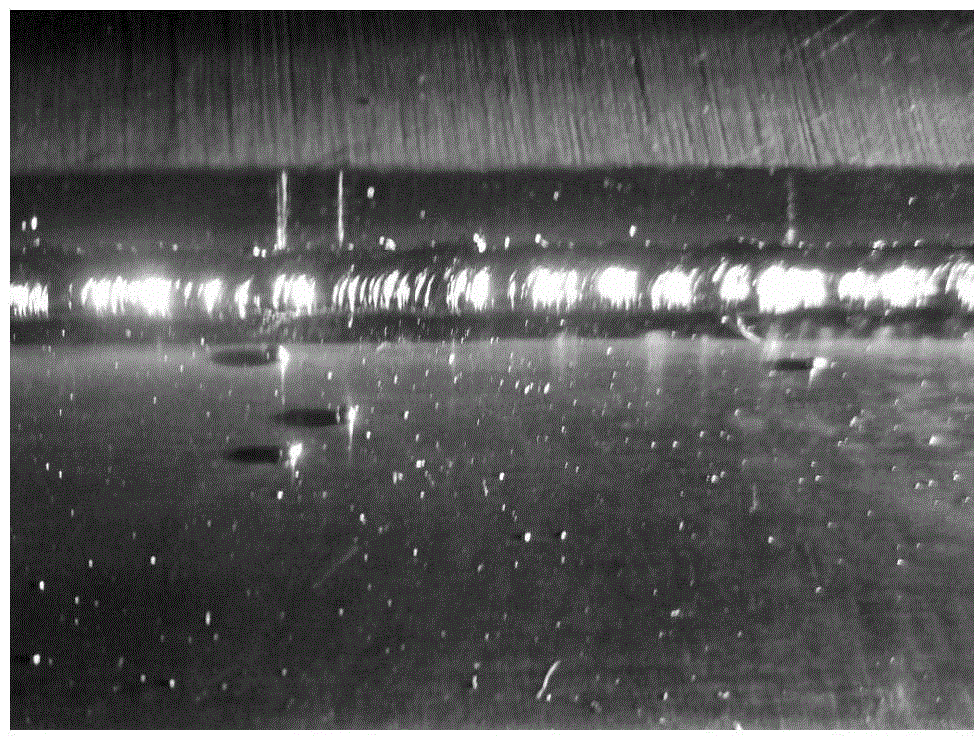

[0019] This embodiment provides a method for controlling spatter in electron beam welding of structural parts with narrow bottom lock, which is characterized in that: the method for controlling spatter in electron beam welding of structural parts with narrow bottom lock, specifically adopts a bottom lock structure with a length of 0.5mm , by adopting the welding method of low-frequency, small-amplitude triangular wave swing and low-line energy input welding mode, and sticking high-temperature resistant tape at a distance of 5mm from the weld seam, the welding can be effectively controlled while ensuring the effective penetration of the weld seam The generation of spatter and secondary weld ablation of the main body of the part, the simulated part welded with the same welding parameters has passed X-ray inspection, there is no defect, and the state of the part meets the requirements of the design drawing;

[0020] Cleaning before welding: The presence of dirt on welding parts wi...

Embodiment 2

[0026] This embodiment provides a method for controlling spatter in electron beam welding of structural parts with narrow bottom lock, which is characterized in that: the method for controlling spatter in electron beam welding of structural parts with narrow bottom lock, specifically adopts a bottom lock structure with a length of 0.5mm , by adopting the welding method of low-frequency, small-amplitude triangular wave swing and low-line energy input welding mode, and sticking high-temperature resistant tape at a distance of 5mm from the weld seam, the welding can be effectively controlled while ensuring the effective penetration of the weld seam The generation of spatter and secondary weld ablation of the main body of the part, the simulated part welded with the same welding parameters has passed X-ray inspection, there is no defect, and the state of the part meets the requirements of the design drawing;

[0027] Cleaning before welding: The presence of dirt on welding parts wi...

Embodiment 3

[0033] This embodiment provides a method for controlling spatter in electron beam welding of structural parts with narrow bottom lock, which is characterized in that: the method for controlling spatter in electron beam welding of structural parts with narrow bottom lock, specifically adopts a bottom lock structure with a length of 0.5mm , by adopting the welding method of low-frequency, small-amplitude triangular wave swing and low-line energy input welding mode, and sticking high-temperature resistant tape at a distance of 5mm from the weld seam, the welding can be effectively controlled while ensuring the effective penetration of the weld seam The generation of spatter and secondary weld ablation of the main body of the part, the simulated part welded with the same welding parameters has passed X-ray inspection, there is no defect, and the state of the part meets the requirements of the design drawing;

[0034] Cleaning before welding: The presence of dirt on welding parts wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com