A kind of 3D ceramic clay printer and printing process

A technology of printers and clay, applied in the direction of ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of limited application range and inability to meet the needs of 3D printing products, and achieve simple adjustment, stability assurance, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

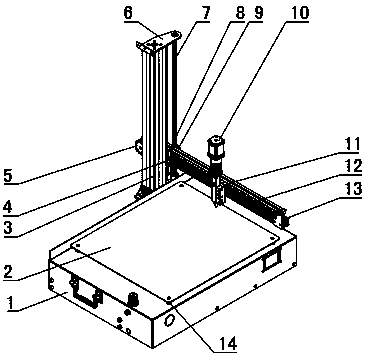

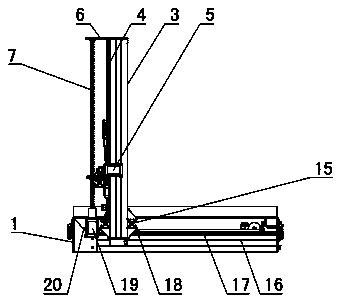

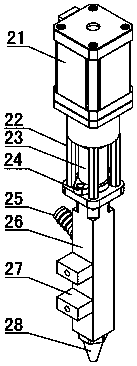

[0038] Figure 1~8 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~8 The present invention will be further described.

[0039] A 3D clay printer, comprising a storage tank 30, an extrusion head 10 connected to the storage tank 30, and a walking mechanism that drives the movement of the extrusion head 10, the upper end of the storage tank 30 is also connected with compressed air, and the compressed air will store The clay in the feed tank 30 is pressed into the extrusion head 10 and extruded by the extrusion head 10; the extrusion head 10 includes an extrusion shell 26, a screw rod 29 in the extrusion shell 26, and a nozzle 28 below the extrusion shell 26. And extrusion motor 21, the upper end of extruding housing 26 is provided with motor base, and extrusion motor 21 is arranged on the top of motor base, and the output shaft of extrusion motor 21 passes through motor base and is coaxially connected with screw rod 29; Feed pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com