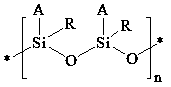

A kind of aminosiloxane series decarburization solvent and preparation method thereof

An aminosiloxane and decarburization technology, applied in separation methods, chemical instruments and methods, reagents, etc., can solve the problems of high regeneration energy consumption, harsh conditions, easy volatility, etc., and achieve low desorption energy, mild reaction conditions, Low volatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

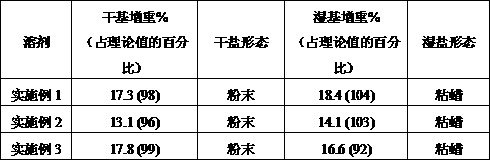

Embodiment 1

[0026] Add 68.4 g of allylamine and 0.78 g of catalyst (3000 ppm) into a 250 mL three-necked flask with a condensing reflux tube, mix and stir evenly, then add 600 g of low-hydrogen silicone oil (hydrogen content 0.20%), and turn on the heating equipment at the same time, The temperature was controlled at 50-60 °C, reacted for 2 h, and then added dropwise 0.33 g of catalyst. After the dropwise addition, the temperature was raised to 100 °C, kept for 2 h, and finally brought to a low boil.

Embodiment 2

[0028] Add 68.4 g of allylamine and 0.52 g of catalyst (1000 ppm) into a 250 mL three-necked flask with a condensing reflux tube, mix and stir evenly, then add 80.4 g of hydrogen-containing double caps, and turn on the heating equipment at the same time, and control the temperature at 50-60 ℃, reacted for 2 h, then added 0.22 g of catalyst dropwise, raised the temperature to 100 °C after the dropwise addition, kept the temperature for 2 h, and finally pumped to a low boil.

Embodiment 3

[0030] Add 68.4 g of allylamine and 0.54 g of catalyst (1000 ppm) into a 250 mL three-necked flask with a condensing reflux tube, mix and stir evenly, then add 85.7 g of hydrogen-containing rings, and turn on the heating equipment at the same time, and control the temperature at 50~60 °C , reacted for 2 h, and then added 0.23 g of catalyst dropwise. After the dropwise addition, the temperature was raised to 100 ° C, kept for 2 h, and finally pumped to a low boil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com