Method for Improving the Distribution of Catalytic Cracking Products by Utilizing Heavy Carbon Nine

A catalytic cracking and product technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of waste of resources, pollution, production scale limitation, etc., and achieve the effect of increasing efficiency, avoiding environmental pollution, and increasing diesel yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

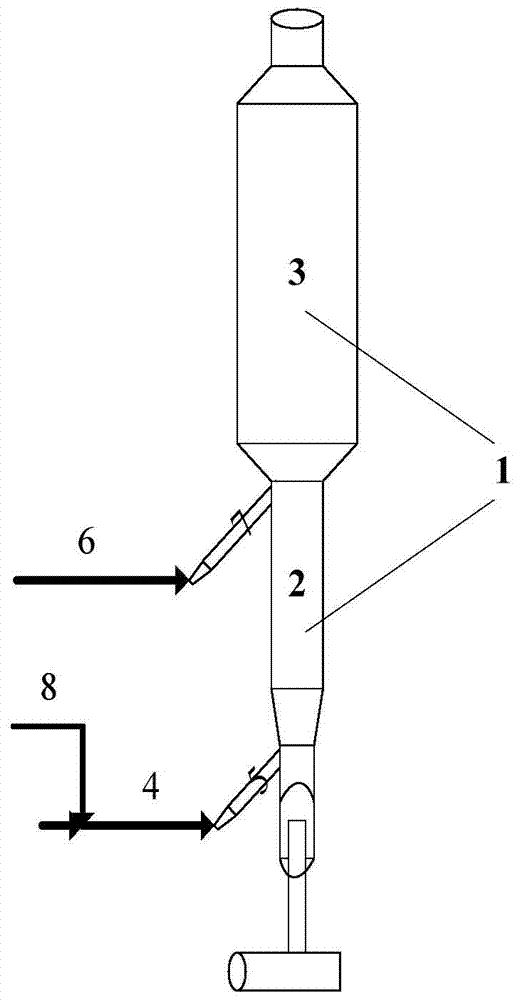

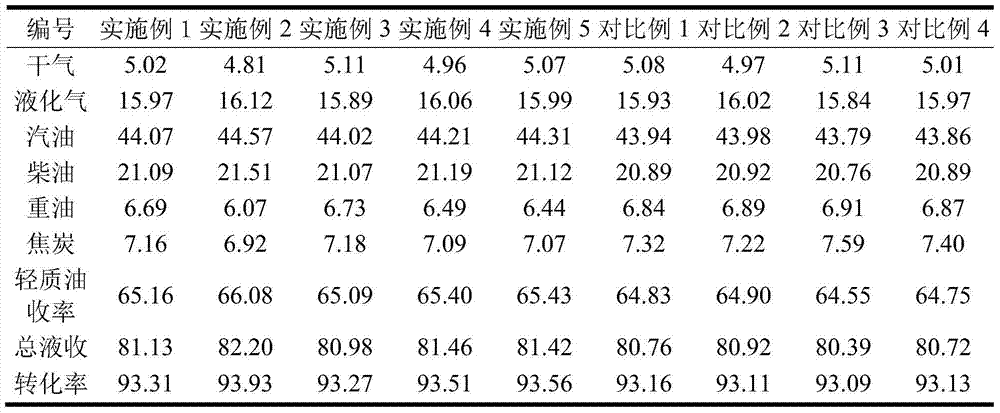

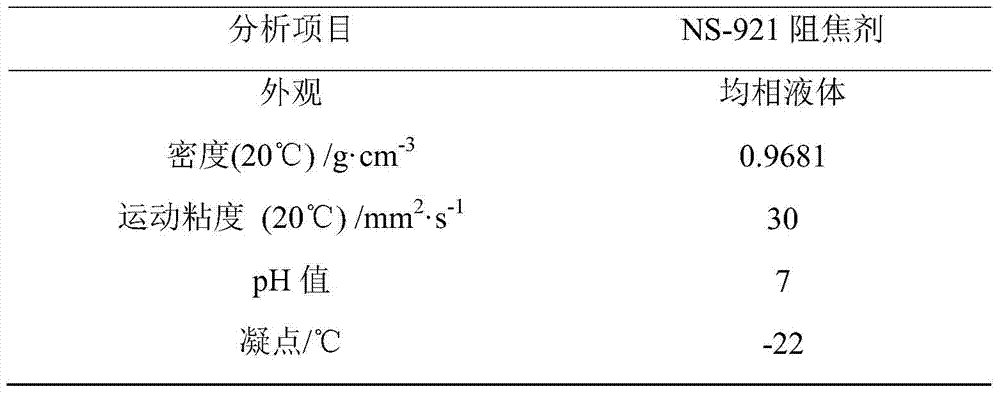

[0027] Use heavy carbon nine as quenching oil to control the catalytic cracking reaction in the riser, heavy carbon nine is injected into riser reactor 1 through quenching oil pipeline 6 and quenching oil nozzle 7, and injection temperature is 40 ℃, and injection pressure is 0.4Mpa, The injection rate is 2wt% of the raw material oil feed rate, and the coking inhibitor NS-921 is mixed with the raw material oil from the pipeline 4 through the pipeline 8 and enters the reactor 1 through the raw material oil nozzle 5 simultaneously, and the addition amount of the coking inhibitor is 100ug / g.

Embodiment 2

[0029] Use heavy carbon nine as quenching oil to control the catalytic cracking reaction in the riser, heavy carbon nine is injected into the riser reactor 1 through the quenching oil pipeline 6 and quenching oil nozzle 7, the injection temperature is 40 ℃, and the injection pressure is 0.4Mpa , the injection rate is 5wt% of the raw material oil feed rate, while the coking inhibitor NS-921 is mixed with the raw material oil from the pipeline 4 through the pipeline 8 and enters the reactor 1 through the raw material oil nozzle 5, and the addition amount of the coking inhibitor is 100ug / g.

Embodiment 3

[0031] Use heavy carbon nine as quenching oil to control the catalytic cracking reaction in the riser, heavy carbon nine is injected into the riser reactor 1 through the quenching oil pipeline 6 and quenching oil nozzle 7, the injection temperature is 40 ℃, and the injection pressure is 0.4Mpa , the injection rate is 10wt% of the raw material oil feed rate, and the coking inhibitor NS-921 is mixed with the raw material oil from the pipeline 4 through the pipeline 8 and enters the reactor 1 through the raw material oil nozzle 5 simultaneously, and the addition amount of the coking inhibitor is 100ug / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com