Deep dealkalizing method of red mud in alumina factory

A deep dealkalization and aluminum plant technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of low concentration of waste liquid, high dealkalization efficiency, high cost of alkali recovery, etc. Achieve the effects of low process energy consumption, high dealkalization efficiency, and low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

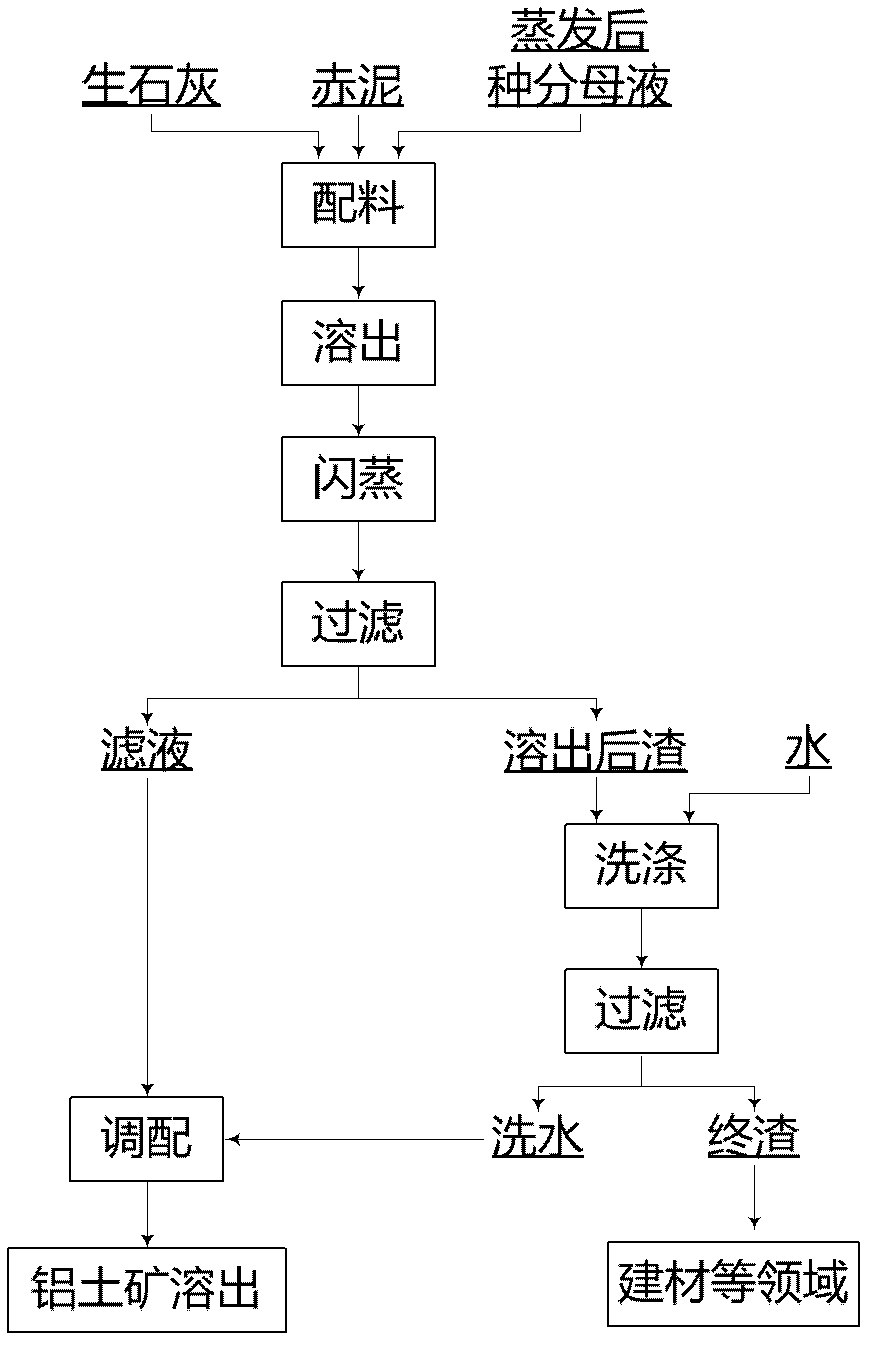

Method used

Image

Examples

Embodiment 1

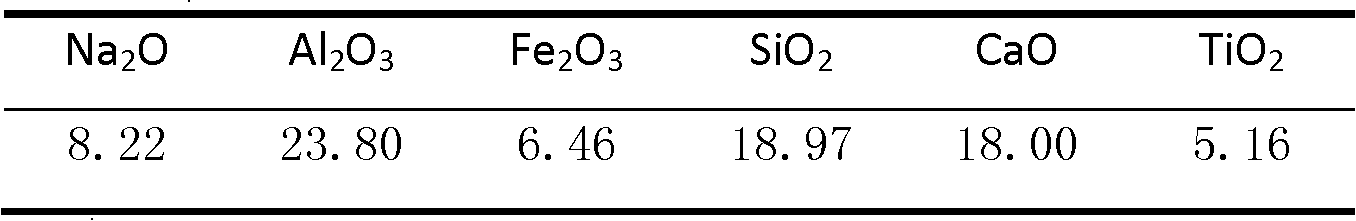

[0019] Taking the red mud of an alumina plant in Henan as an example, the mass percentage (%) of the chemical composition of the red mud in the plant is as follows:

[0020]

[0021] Mix the red mud with the evaporated mother liquor with an alkali concentration of 200g / L, add quicklime so that the total calcium-silicon ratio of the slurry is 3, raise the temperature to 300°C, and react for 1.5 hours, and the liquid-solid ratio is 6. The slurry was naturally cooled to 110°C, then separated by filtration and washed. After the filter residue was dried and analyzed, the mass percent content of sodium oxide was 0.31%.

Embodiment 2

[0023] Mix the red mud of the alumina plant in Example 1 with the evaporated seed liquor with an alkali concentration of 300g / L, add quicklime according to the slurry Ca / Si ratio of 3, raise the temperature to 200°C, and react for 1.5 hours, with a liquid-solid ratio of 10. After the reaction, the slurry was naturally cooled to 110° C., filtered, washed, and the filter cake was dried. After analysis, the percentage content of sodium oxide in the final slag was 1.51%.

Embodiment 3

[0025] Mix the red mud of the alumina plant in Example 1 with the mother liquor with an alkali concentration of 260g / L, add quicklime according to the slurry Ca / Si ratio of 2, raise the temperature to 300°C, and react for 0.5 hours, with a liquid-solid ratio of 3. After the reaction, the slurry is pumped into the flash tank, flashed to 115°C, and then pumped into the filter for filtration. The obtained slag phase was fully washed and filtered. After the filter residue was dried, its sodium oxide percentage was analyzed to be 0.89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com