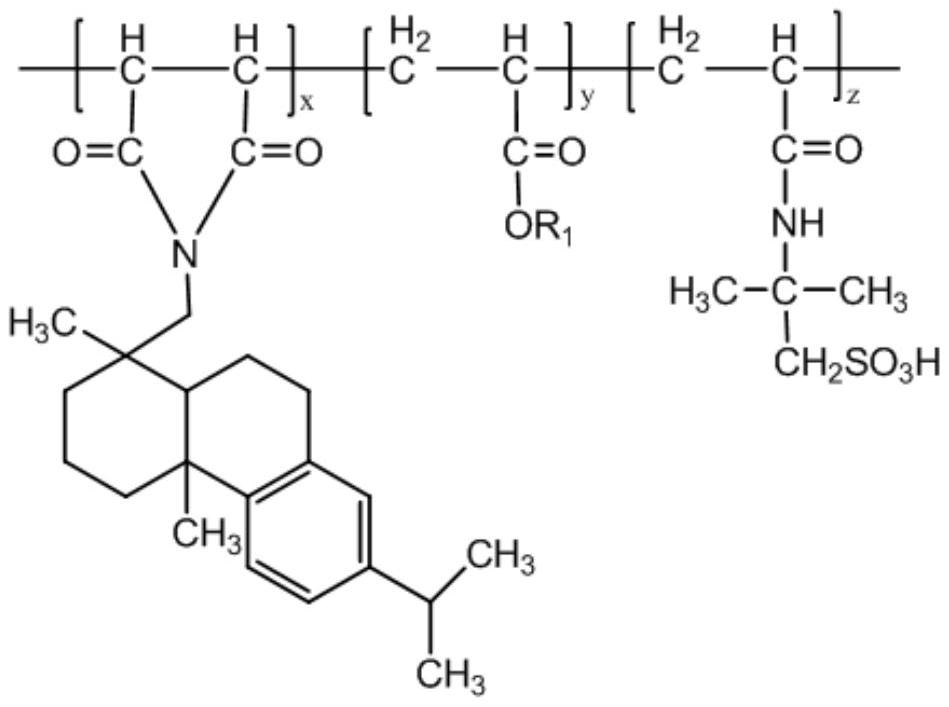

Water-soluble crude oil pour point depressant and its preparation method and application

A crude oil pour point depressant and water-soluble technology, applied in the field of water-soluble crude oil pour point depressant and its preparation, can solve the problems of high cost, complexity, difficult injection, etc., and achieve the effects of environmental friendliness, simple operation and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve 9.81g of maleic anhydride in 39.24g of acetone, put it in a reaction flask, dissolve 28.55g of rosinamine in 114.20g of petroleum ether, and slowly add it dropwise to maleic anhydride in an ice-water bath. After the addition is complete, stir and reflux at 60°C for 2 hours, filter, and recrystallize with acetone to obtain a maleic anhydride derivative;

[0030] (2) Add 36.16g of maleic anhydride derivatives, 16.23g of tetradecyl acrylate, and 51.79g of toluene obtained above into the reaction flask, and pass N 2 Protection; slowly add 0.24g of dibenzoyl peroxide dropwise, and react at a constant temperature for 5 hours at 70°C. After the reaction, cool to about 40°C; dissolve 20.72g of 2-acrylamido-2-methylpropanesulfonic acid into 20.72g of N,N-dimethylformamide, then pour it into the reaction flask, continue to dropwise add 0.49g of dibenzoyl peroxide, react at a constant temperature at 70°C for 7 hours, and add 0.58g of hydroquinone at the end of the rea...

Embodiment 2

[0034] (1) Dissolve 9.81g of maleic anhydride in 39.24g of acetone, place in a reaction flask, dissolve 22.84g of rosinamine in 91.36g of petroleum ether, and slowly add it dropwise to maleic anhydride in an ice-water bath. After completion, stir and reflux at 70°C for 2 hours, filter, and recrystallize with acetone to obtain maleic anhydride derivatives;

[0035] (2) Add 31.21g of maleic anhydride derivatives, 23.72g of hexadecyl acrylate and 56.37g of xylene obtained above into the reaction flask, and pass N 2 Protection; slowly add 0.46g of azobisisobutyronitrile dropwise, and react at a constant temperature at 80°C for 6h. After the reaction, cool to about 40°C; dissolve 20.72g of 2-acrylamido-2-methylpropanesulfonic acid into 20.72g of N,N-dimethylacetamide, then pour it into the reaction flask, continue to dropwise add 0.47g of azobisisobutyronitrile, and react at a constant temperature of 80°C for 8 hours, and add 0.77g of hydroquinone after the reaction is completed. ...

Embodiment 3

[0039] (1) Dissolve 9.81g of maleic anhydride in 39.24g of acetone, put it in a reaction flask, dissolve 28.55g of rosinamine in 114.20g of petroleum ether, and slowly add it dropwise to maleic anhydride in an ice-water bath. After completion, stir and reflux for 2 hours at 80°C, filter, and then recrystallize with acetone to obtain maleic anhydride derivatives;

[0040](2) Add 36.16g of maleic anhydride derivatives, 32.46g of tetradecyl acrylate, and 95.06g of toluene obtained above into the reaction flask, and pass N 2 Protection: Slowly add 0.62g of azobisisobutyronitrile dropwise, and react at a constant temperature at 90°C for 6h. After the reaction, cool to about 50°C; dissolve 31.05g of 2-acrylamido-2-methylpropanesulfonic acid into 37.26g of N,N-dimethylacetamide, then pour it into the reaction flask, continue to dropwise add 0.92g of azobisisobutyronitrile, react at a constant temperature of 90°C for 5 hours, and add 1.32g of hydroquinone at the end of the reaction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com