Module splicing structure

A connection structure and module connection technology, which is applied in the direction of connection components, thin plate connections, dovetail connections, etc., can solve the problems of complicated structural components, unfavorable factory processing, and heavy installation and disassembly workload, and achieve flexible and diverse structural combinations , easy factory processing, less resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

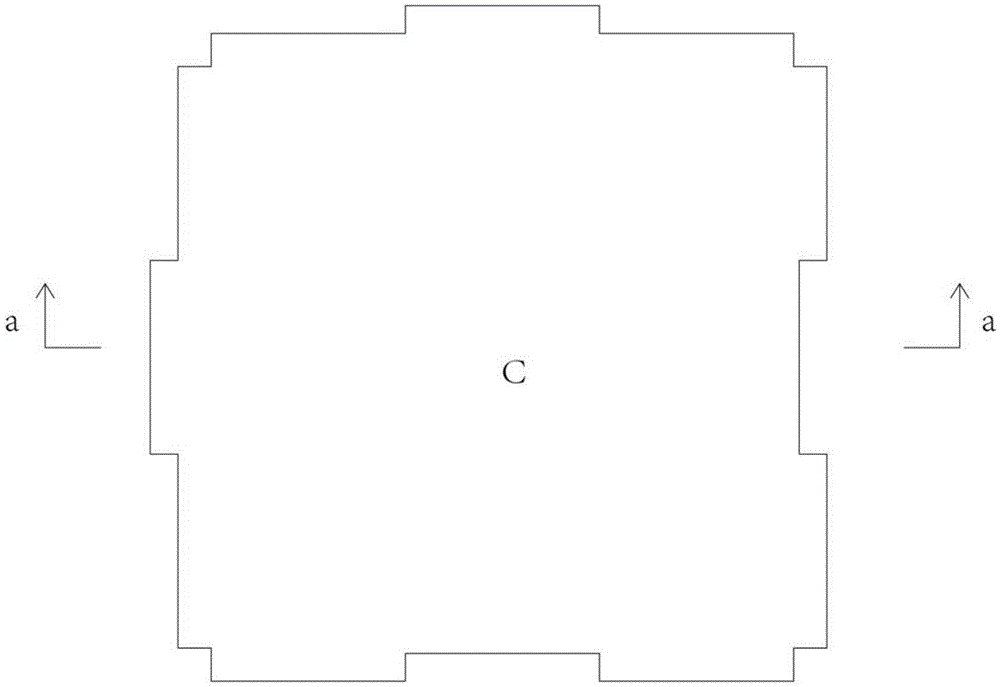

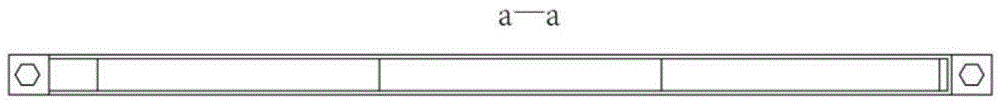

[0186]A modular splicing structure. The structure includes a splicing module C, a connecting member A, a reinforcing accessory B, and functional accessories D, E, and G. It is characterized in that: the splicing module C is three-dimensional and has a basic shape (note: the basic shape is the shape of the splicing module body or the shape after the convex, concave, and convex-concave connection structures are removed when the splicing module is provided with a convex, concave, and convex-concave connection structure ) is a component having a triangle, square, rectangle, rhombus, parallelogram, trapezoid, pentagon, hexagon, heptagon, octagon, nonagonal closed curved maximum surface projection shape. The connecting structures of these splicing modules C are provided with holes, and these holes have the following characteristics: the outline is a three-dimensional or curved three-dimensional prism or truss. The cross-sectional shape is triangle, square, rectangle, rhombus, paral...

Embodiment 2

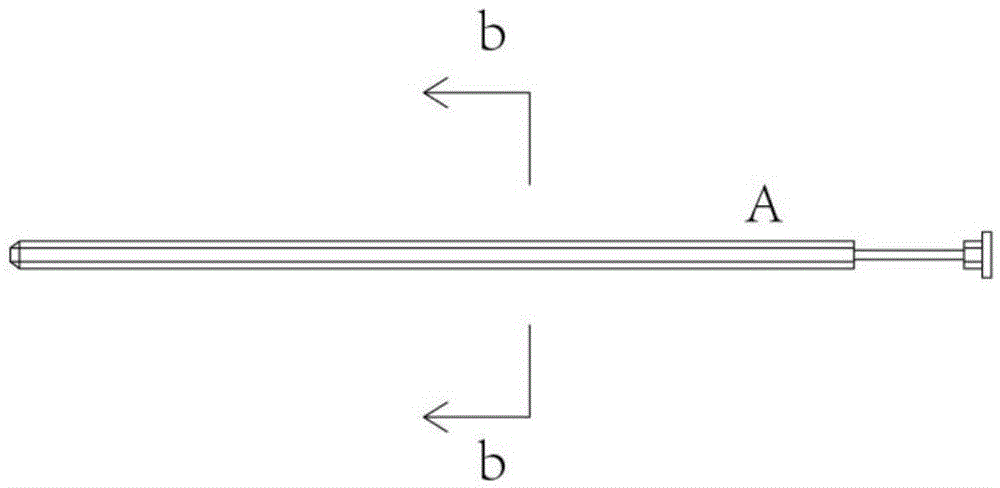

[0209] A modular splicing structure. The structure includes a splicing module C and a connecting member A. It is characterized in that: the splicing module C is three-dimensional and has a basic shape (note: the basic shape is the shape of the splicing module body or the shape after the convex, concave, and convex-concave connection structures are removed when the splicing module is provided with a convex, concave, and convex-concave connection structure ) is a component with a square or rectangular maximum surface projection shape. These splicing modules C are provided with holes, and these holes have the following characteristics: the outline is a plane three-dimensional or curved three-dimensional prism. The cross-sectional shape is triangle, square, rectangle, rhombus, parallelogram, trapezoid, star, pentagon, hexagon, heptagon, octagon, nonagon, closed curve.

[0210] The connection member A has the following characteristics: the outline is a plane solid or a curved sol...

Embodiment 3

[0217] A modular splicing structure. The structure includes a splicing module C and a connecting member A. It is characterized in that: the splicing module C is three-dimensional and has a basic shape (note: the basic shape is the shape of the splicing module body or the shape after the convex, concave, and convex-concave connection structures are removed when the splicing module is provided with a convex, concave, and convex-concave connection structure ) is a component with a square or rectangular maximum surface projection shape. The four corners or the back of these splicing modules C are provided with grooves, and these grooves have the following characteristics: the outline is cuboid, cube, quadrangular prism or hexagonal prism, octagonal prism, and the cross-sectional shape is rectangular, square, parallelogram, trapezoidal or wedge-shaped, T-shaped .

[0218] The connecting member A has the following characteristics: the outline is a cuboid, cube, quadrangular prism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com