Textile drying machinery

A mechanical and textile technology, applied in the field of textile drying machinery, can solve the problems of affecting the drying effect of textiles, waste of resources, and uneven temperature of the drying box, so as to improve the drying effect, reduce energy consumption, and improve drying efficiency. The effect of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

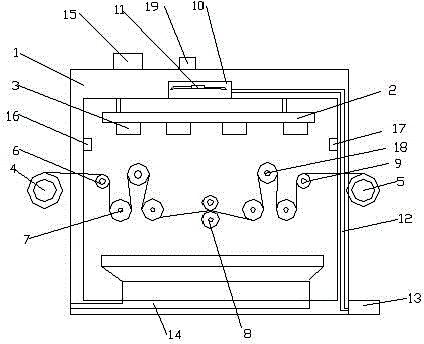

[0019] like figure 1 As shown, a textile drying machine of the present invention includes a drying box 1, a slide rail 2 is provided on the top of the drying box 1, and a plurality of dryers 3 are arranged on the slide rail 2, in order to ensure The temperature distribution inside the drying box is even, which improves the drying quality and efficiency, and the dryer 3 is designed to slide freely on the slide rail 2 . The front and rear sides of the drying cabinet 1 are respectively provided with an unwinding mechanism 4 and a winding roller 5. In the drying cabinet 1, a front guide roller 6, a heating Roller group 7, pressure roller group 8 and rear guide roller 9, the top of described drying cabinet 1 is provided with collection window 10, is provided with fan 11 in collection window 10, and described collection window 10 is connected with insulation pipe 12, so The bottom of the heat preservation pipe 12 is connected with a water collecting tank 13 , and the side of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com