Copper strip flexible connector and forming production line thereof

A soft connection and production line technology, applied in the direction of connection, contact parts, conductors, etc., can solve the problems of increased process steps, acid reflux, residual plating solution, etc., and achieve the effect of simple process, low cost and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

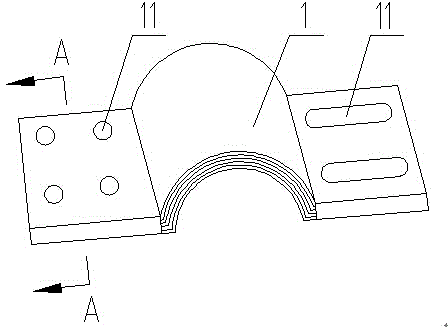

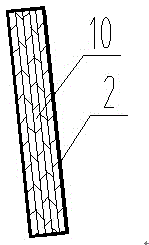

[0031] Embodiment one: see figure 1 As shown, a copper strip flexible connection is formed by stacking multiple pieces of red copper foils with a thickness of 0.05 to 0.3 mm. The multiple pieces of the copper foil 10 at both ends of the copper strip flexible connection 1 are pressure-welded together. The outside of the two ends of the flexible connection of the copper strip that is pressure-welded is coated with a silver-plated layer 2, see figure 2 .

[0032] Both ends of the flexible copper strip connection 1 are processed with a plurality of bolt connection holes 11 .

[0033] In this embodiment, the bolt connection hole 11 at one end of the flexible copper strip connection 1 is a waist-shaped hole. Through the design of the waist-shaped hole, the installation position of the copper tape flexible connection end and the bending degree of the copper tape flexible connection can be adjusted according to the distance between the parts to be connected.

[0034] Embodiment 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap