A wind power slip ring brush assembly integral forming device

A slip ring brush, integral molding technology, applied in the direction of motor generator connector, brush manufacturing, etc., can solve the problems of high molding cost and low efficiency, and achieve the effect of low molding cost, convenient replacement and diversified functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

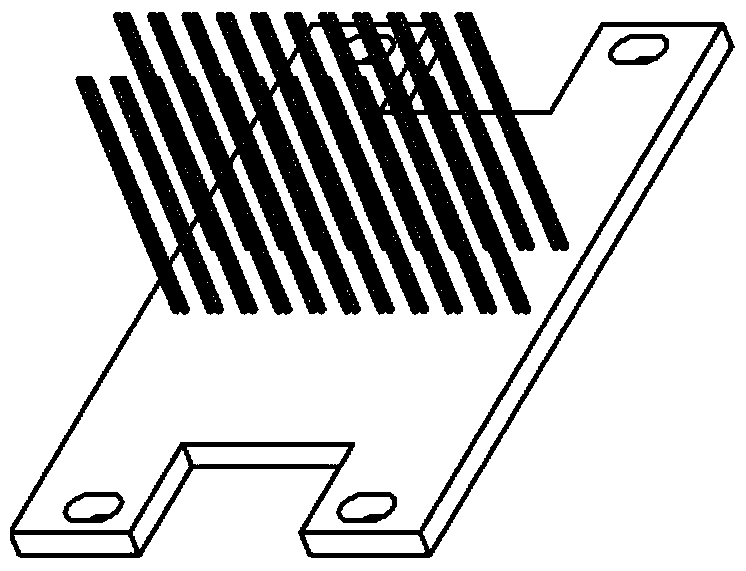

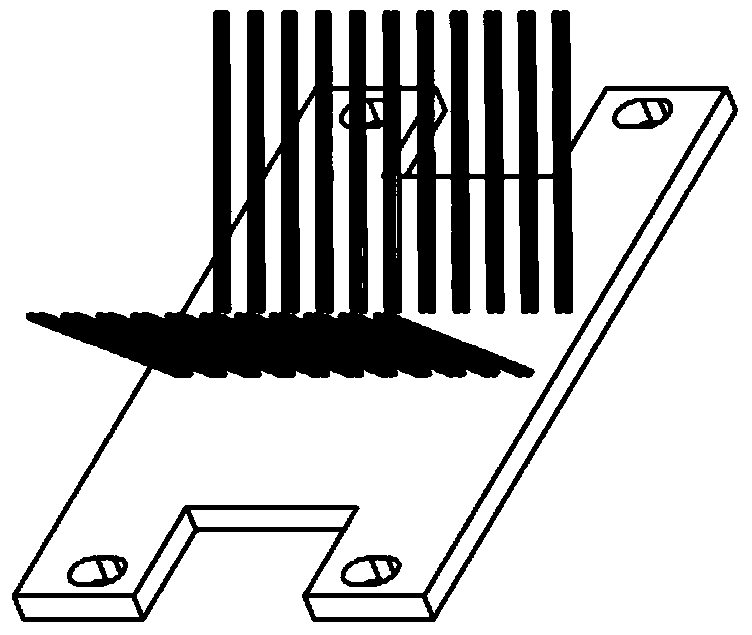

[0022] The brush assembly 10 to be produced is as figure 1 As shown, the U-shaped brushes are installed on the brush holder one by one, the extension of the brush arms is the same, and the brush arms are in a parallel and symmetrical structure, and the installed brush assembly 10 is placed on the forming device work location. The final brush assembly 10 is to be processed as figure 2 In the structure shown, the parallel brush arms on both sides are symmetrically arranged at an angle of 80°, and the bending positions of the brushes are consistent.

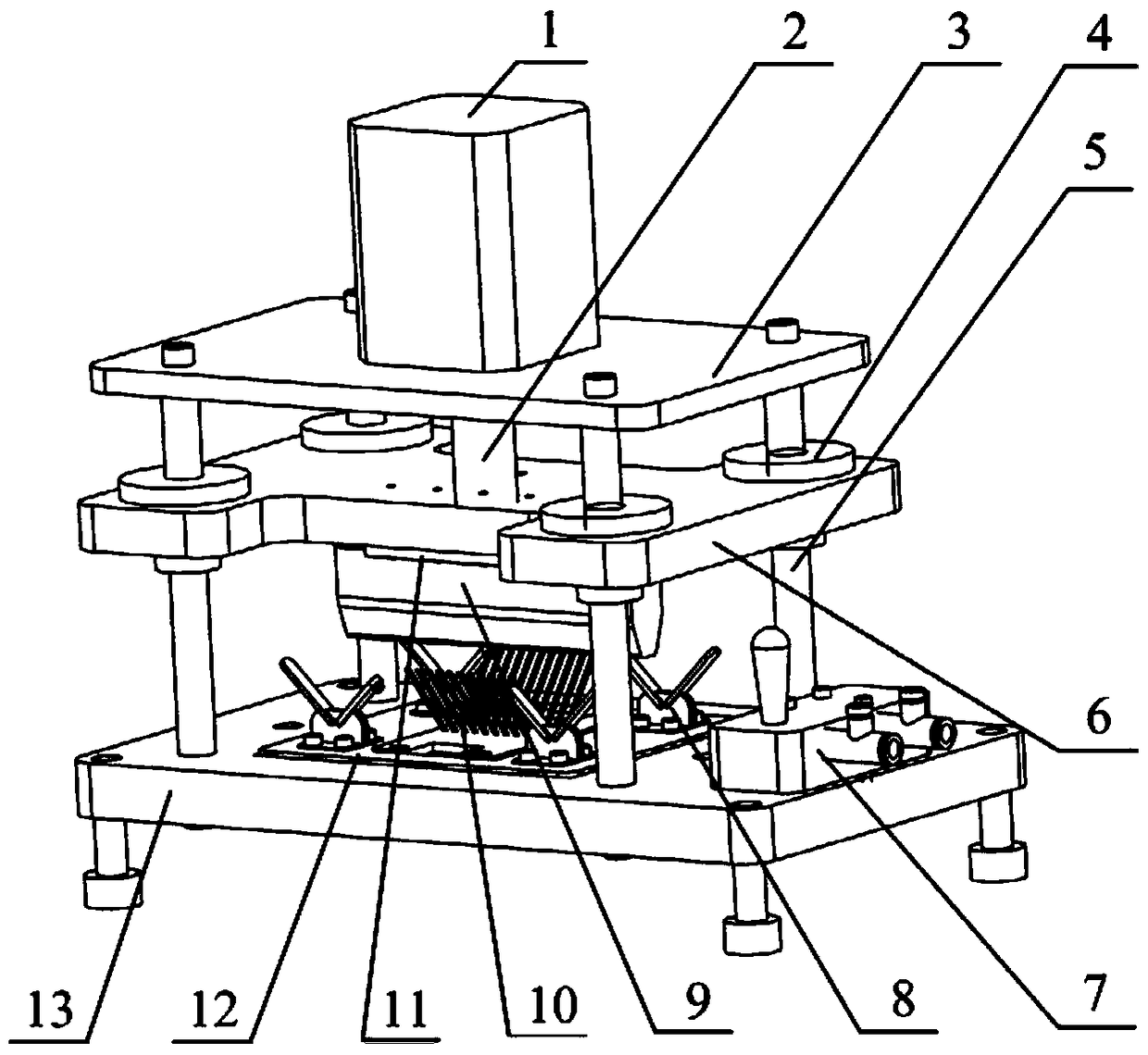

[0023] A wind power slip ring brush assembly integral forming device, such as image 3 , Figure 4 , Figure 5 As shown, it includes: cylinder 1, buffer sleeve 2, top plate 3, linear bearing 4, bearing slide rail 5, stamping plate 6, cylinder manual valve 7, brush assembly quick lock wrench 8, die 9, brush assembly 10, die Locking structure 11 , brush assembly adapter plate 12 , base 13 . The cylinder 1 is installed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com