High-comfort protective garment fabric, protective garment and manufacturing method of high-comfort protective garment fabric

A technology for protective clothing and comfort, which is applied in the field of high-comfort protective clothing fabrics and protective clothing. It can solve the problems of little improvement in comfort, unstable after-burning index, unavoidable dyeing and cost of smoldering, and achieve high heat Protection value, effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

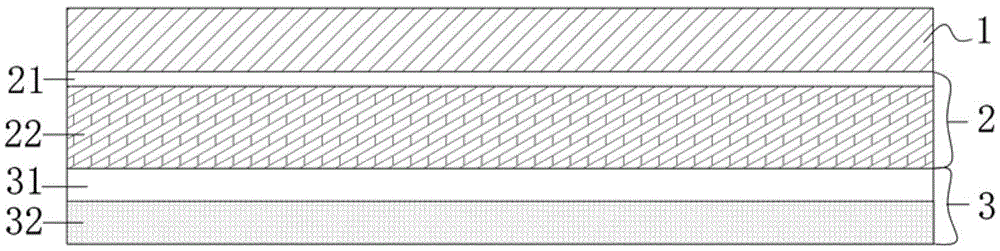

[0062] High-comfort protective clothing fabric, from the outside to the inside, includes a composite outer layer, a waterproof breathable layer and a thermal insulation comfort layer.

[0063] The outer layer has a grammage of 210g / m 2 , by the following weight percentages of fiber blended into yarns and woven by common conventional methods: 93% meta-aramid fiber, 5% para-aramid fiber, 2% antistatic fiber.

[0064] The waterproof and breathable layer has a grammage of 90g / m 2 , consists of the following raw materials in parts by weight: 70 parts of aramid spunlace nonwoven fabric and 20 parts of PTFE film.

[0065] The aramid spunlace nonwoven fabric is woven from 80wt% meta-aramid fibers and 20wt% para-aramid fibers by conventional methods (wherein wt% is mass percentage).

[0066] The PTFE membrane is a polytetrafluoroethylene membrane with a thickness of 2.5 μm, and micropores are uniformly arranged on the polytetrafluoroethylene membrane, the diameter of the micropores i...

Embodiment 2

[0071] Such as figure 1 As shown, the high-comfort protective clothing fabric, from the outside to the inside, includes a composite outer layer 1, a waterproof and breathable layer 2 and a heat-insulating and comfortable layer 3.

[0072] The outer layer 1 has a grammage of 210g / m 2 , by weaving and weaving yarns blended with the following weight percentages of fibers: 93% meta-aramid fiber, 5% para-aramid fiber, 2% antistatic fiber.

[0073] The waterproof and breathable layer 2 has a gram weight of 90g / m 2 , consists of the following raw materials in parts by weight: 70 parts of aramid spunlace nonwoven fabric and 20 parts of PTFE film.

[0074] The aramid spunlace nonwoven fabric 22 is woven from 80wt% meta-aramid fibers and 20wt% para-aramid fibers (wherein wt% is mass percentage).

[0075] The PTFE membrane 21 is a polytetrafluoroethylene membrane with a thickness of 2.5 μm, the polytetrafluoroethylene membrane is evenly provided with micropores, the diameter of the mi...

Embodiment 3

[0079] High-comfort protective clothing fabric, from the outside to the inside, includes a composite outer layer, a waterproof breathable layer and a thermal insulation comfort layer.

[0080] The outer layer has a grammage of 210g / m 2 , by weaving and weaving yarns blended with the following weight percentages of fibers: 93% meta-aramid fiber, 5% para-aramid fiber, 2% antistatic fiber.

[0081] The waterproof and breathable layer has a grammage of 90g / m 2 , consists of the following raw materials in parts by weight: 70 parts of aramid spunlace nonwoven fabric and 20 parts of PTFE film.

[0082] The aramid spunlace nonwoven fabric is woven from 80 wt% meta-aramid fibers and 20 wt% para-aramid fibers.

[0083] The PTFE membrane is a polytetrafluoroethylene membrane with a thickness of 2.5 μm, and micropores are uniformly arranged on the polytetrafluoroethylene membrane, the diameter of the micropores is 0.8 μm, and the weight is 30 g / m 2 .

[0084] The thermal insulation co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com