Novel automatic production line

An automated production line, a new type of technology, applied in chemical instruments and methods, chemical/physical processes, material granulation and coating, etc., can solve problems such as low production efficiency, uneven particle size, easy damage to equipment, etc., and achieve production efficiency High, less impurities, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

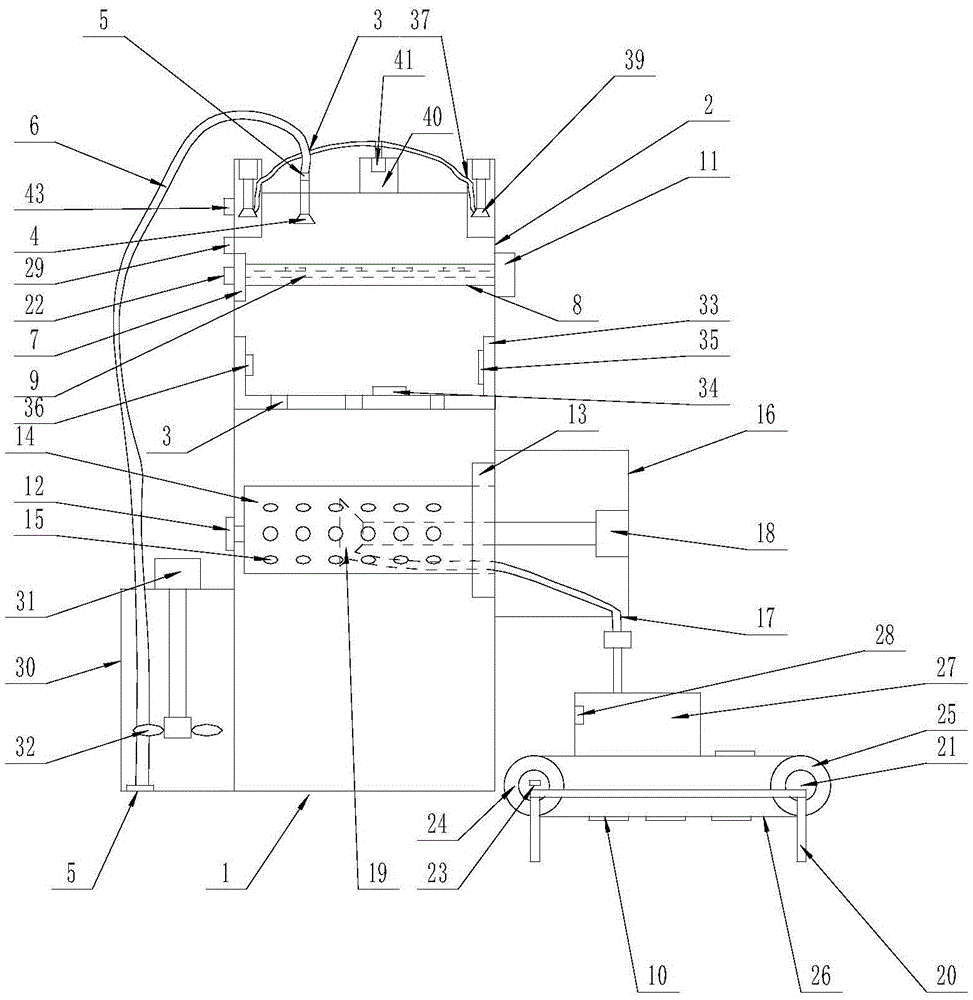

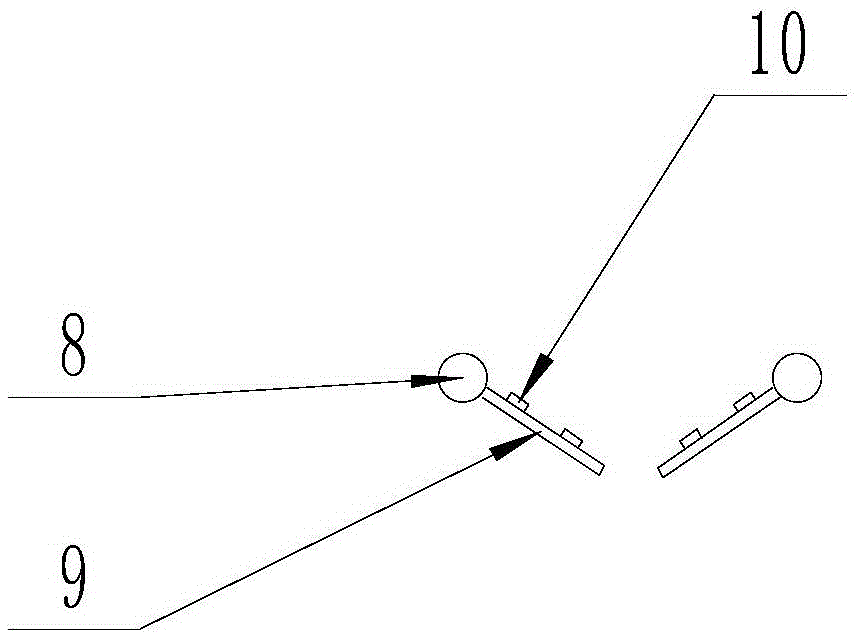

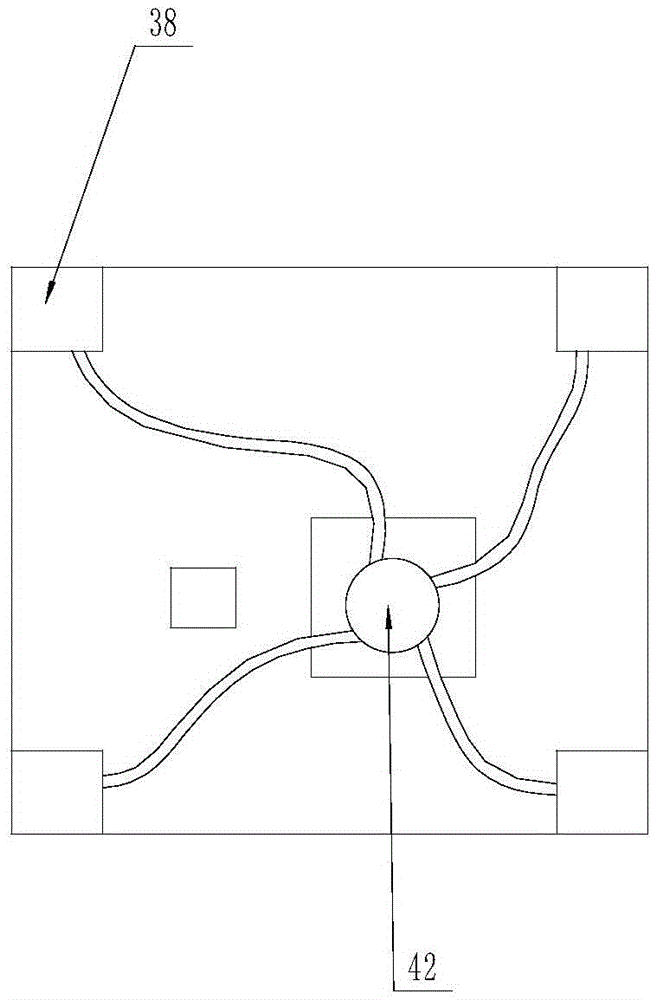

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 Shown, a kind of novel automatic production line comprises frame (1), and described frame (1) is fixedly installed on the ground, and the frame side of described frame (1) is provided with feeding mechanism, and described frame ( 1) A pharmaceutical mechanism is fixedly embedded inside, and the pharmaceutical mechanism consists of a pharmaceutical box (2) fixedly embedded in the frame (1), a round hole (3) opened at the center of the pharmaceutical box (2), The pharmaceutical granule nozzle (4) fixedly embedded in the round hole (3), the connection pipe (6) that is fixedly connected to the suction pump (5) at one end and connected to the pharmaceutical granule nozzle (4) at the other end, is located in the pharmaceutical box Two sets of bearings A (7) on two opposite surfaces of the body (2), rotating shafts A (8) inserted in the corresponding set of bearings A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap