Special-shaped tube steel skeleton automatic variable diameter seam welding machine

A steel frame and special-shaped tube technology, which is applied in the field of automatic variable-diameter roll welding machine for special-shaped tube steel frame, can solve problems such as complex structure, high cost, and sprocket damage, so as to reduce manufacturing costs, ensure welding quality, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

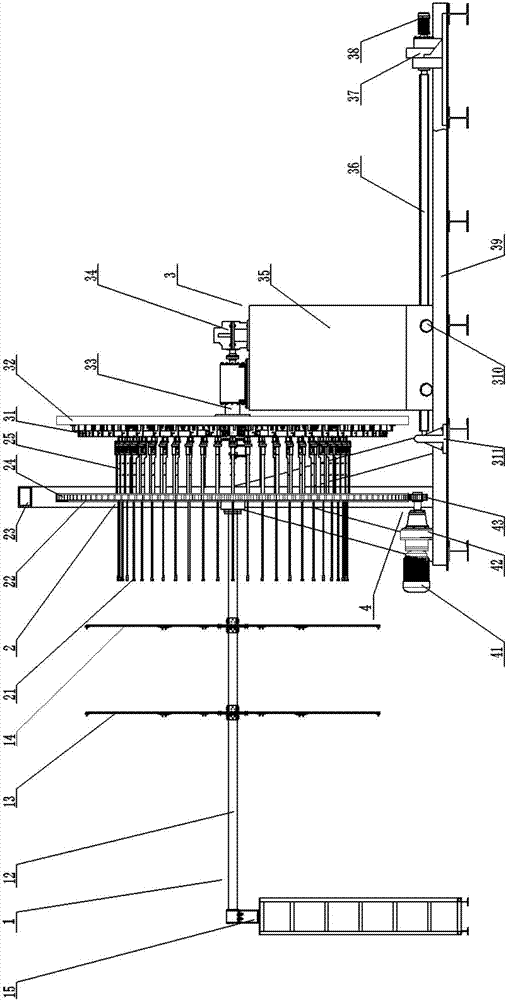

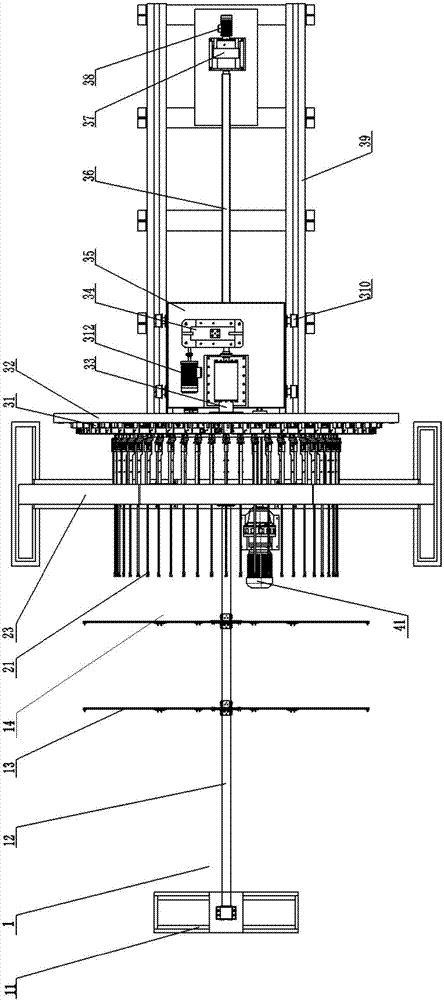

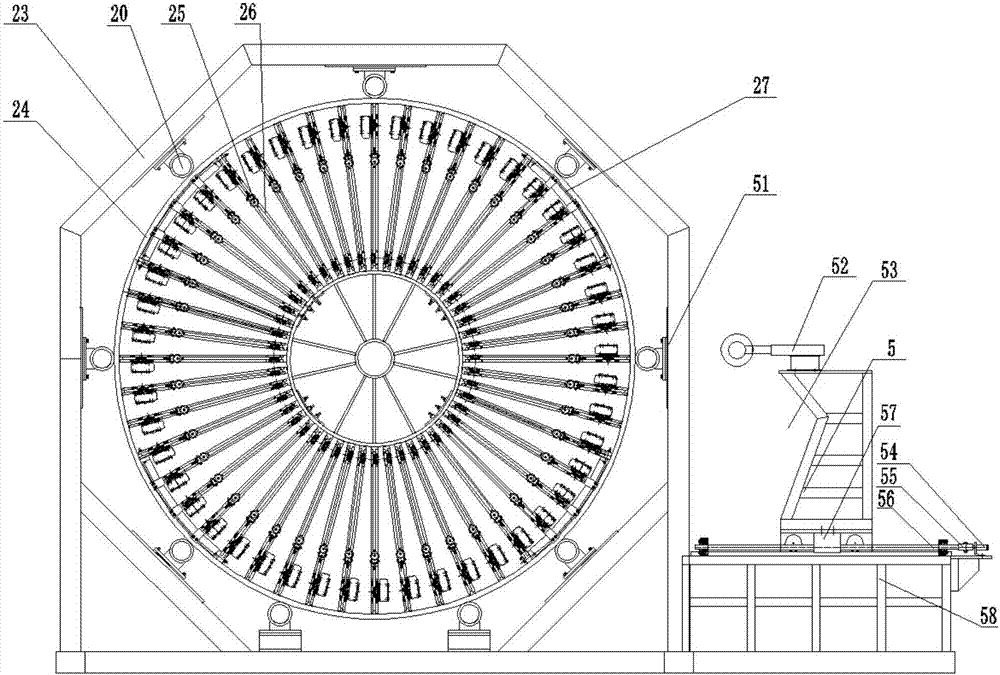

[0038] Such as figure 1 , 2 As shown, the automatic variable-diameter roll welding machine for special-shaped steel bar skeletons of the present invention includes a support mechanism 1 , a diameter-reducing mechanism 2 , a traction mechanism 3 , a driving mechanism 4 and a welding mechanism 5 . The support mechanism 1 is used to support the weight of the longitudinal reinforcement, the variable diameter mechanism 2 is used to change the relative position of the welding seat 25 relative to the center of the main face plate 24, so that the longitudinal reinforcement 324 forms the required steel skeleton cross-sectional shape, and the traction mechanism 3 is used to drag The moving reinforcement skeleton moves longitudinally and realizes the synchronous rotation of its traction faceplate 32 and the main faceplate 24 of the variable diameter mechanism 2. The driving mechanism 4 is used to drive the main faceplate 24 of the variable diameter mechanism 2 to rotate at a constant spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com