Construction method of large-scale cast-in-place thin-walled high piers integrally formed with rigid skeleton reinforcement cage

A rigid skeleton, integral forming technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of large investment in steel, high cost, and low precision of high pier main bars, achieve the overall verticality accuracy, reduce steel The effect of investment and accurate rebar position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this embodiment, the steel structure welding process, bolt connection construction process, formwork setting process, and concrete pouring construction process will not be repeated in this implementation, and the embodiments of the structure related to the present invention will be focused on.

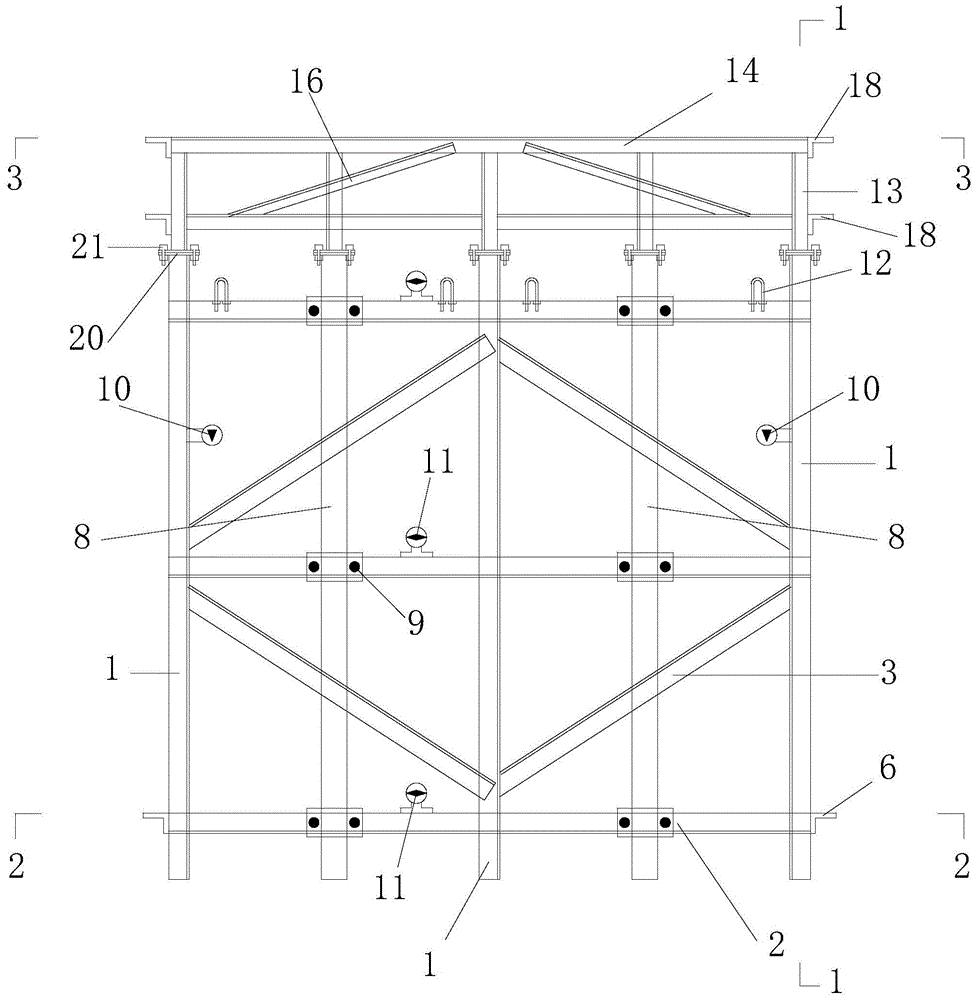

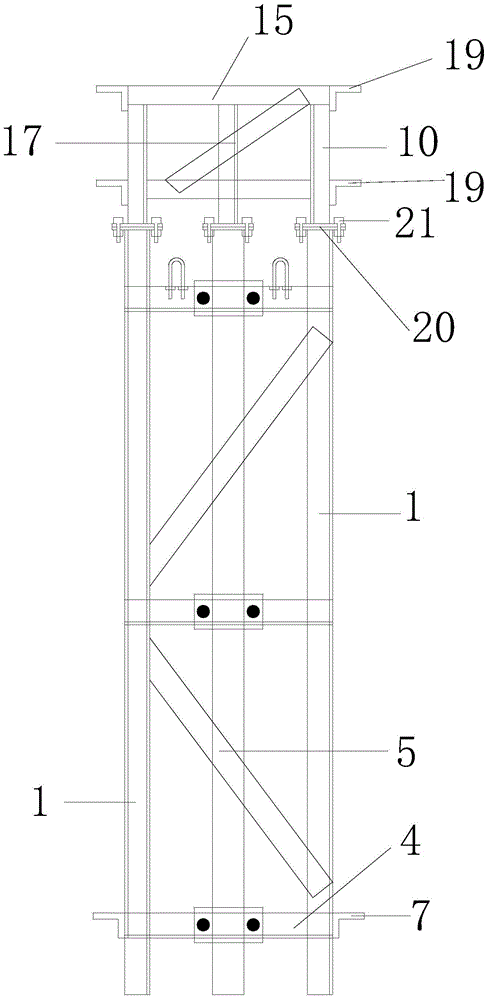

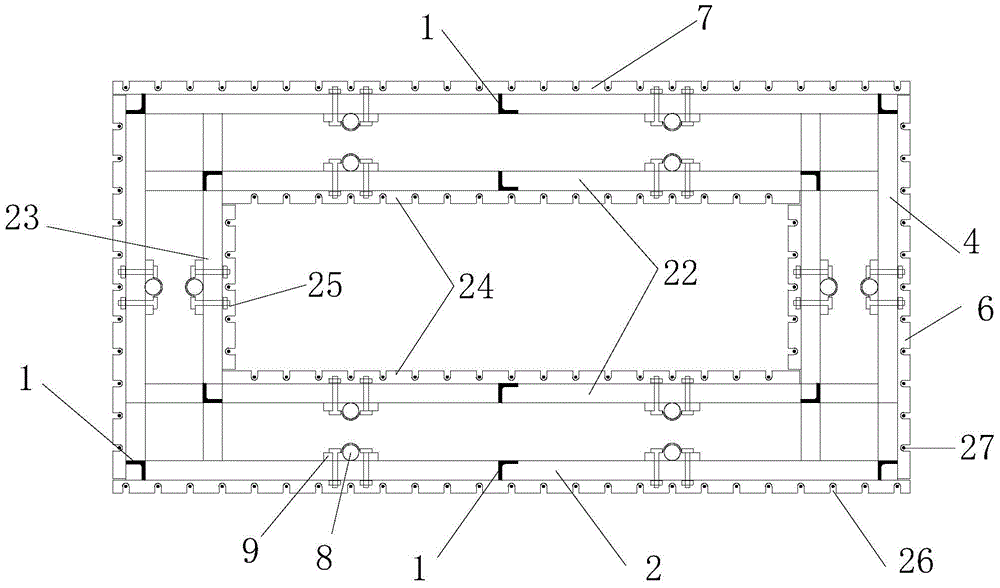

[0034] figure 1 It is a structural schematic diagram of a large-scale cast-in-place thin-walled high pier integrally formed by a rigid skeleton reinforcement cage of the present invention. refer to figure 1 As shown, the large-scale cast-in-place thin-walled high pier structure of the present invention as a whole with a stiffened frame reinforcement cage mainly includes: a stiffened frame vertical bar 1; a stiffened frame outer horizontal bar A2; a stiffened frame shear brace A3; a stiffened frame Horizontal bar B4 on the outer layer of the skeleton; B5 stiff frame shear brace; A6 outer positioning angle steel; B7 outer positioning angle steel; 8 steel pipes; 9 fasteners; 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com