Semi-prefabricated concrete column module

A concrete block and concrete technology, which is applied to columns, piers, pillars, etc., can solve problems such as difficult quality assurance, hidden safety hazards, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following embodiments.

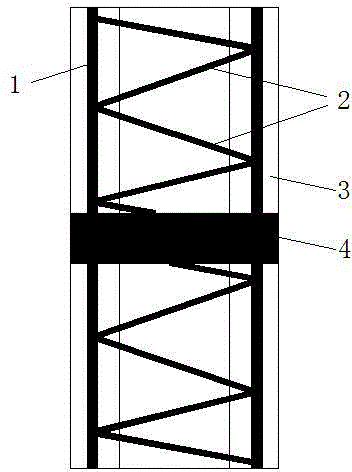

[0013] First, according to the specific design scheme of the columns in the structure, determine the required height and section size of the columns. Then determine the number of modules that need to be divided, and also get the cross-sectional size of each module.

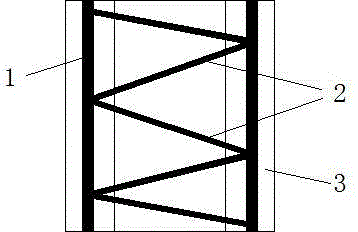

[0014] Prefabricate according to the determined module section size and height: first support the formwork, then fix the position of the required longitudinal reinforcement 1, then bind and fix the spiral reinforcement 2 on the outside of each longitudinal reinforcement 1, and then pour concrete 3. After the concrete 3 is hardened, the formwork is removed to form a column module....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com