Full-automatic clean heat energy recovery device

A heat energy recovery, fully automatic technology, applied in the direction of cleaning heat transfer devices, heat exchanger types, indirect heat exchangers, etc. problems, to reduce the cost of use, improve the service life, and maintain the efficiency of heat recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

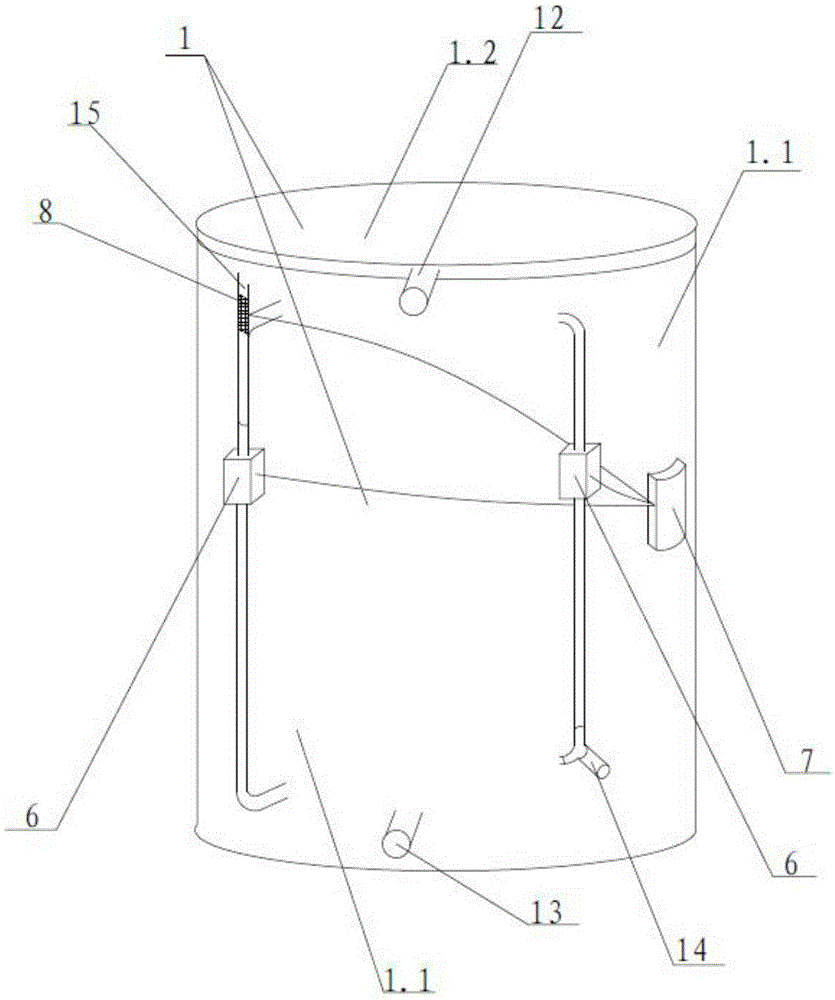

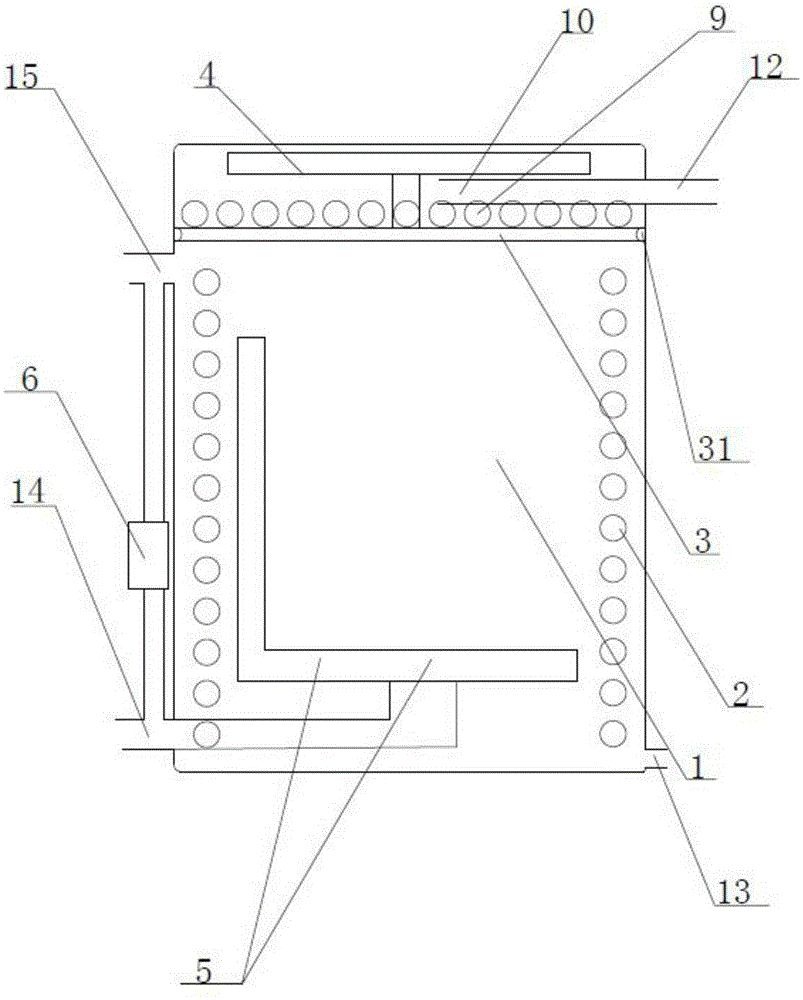

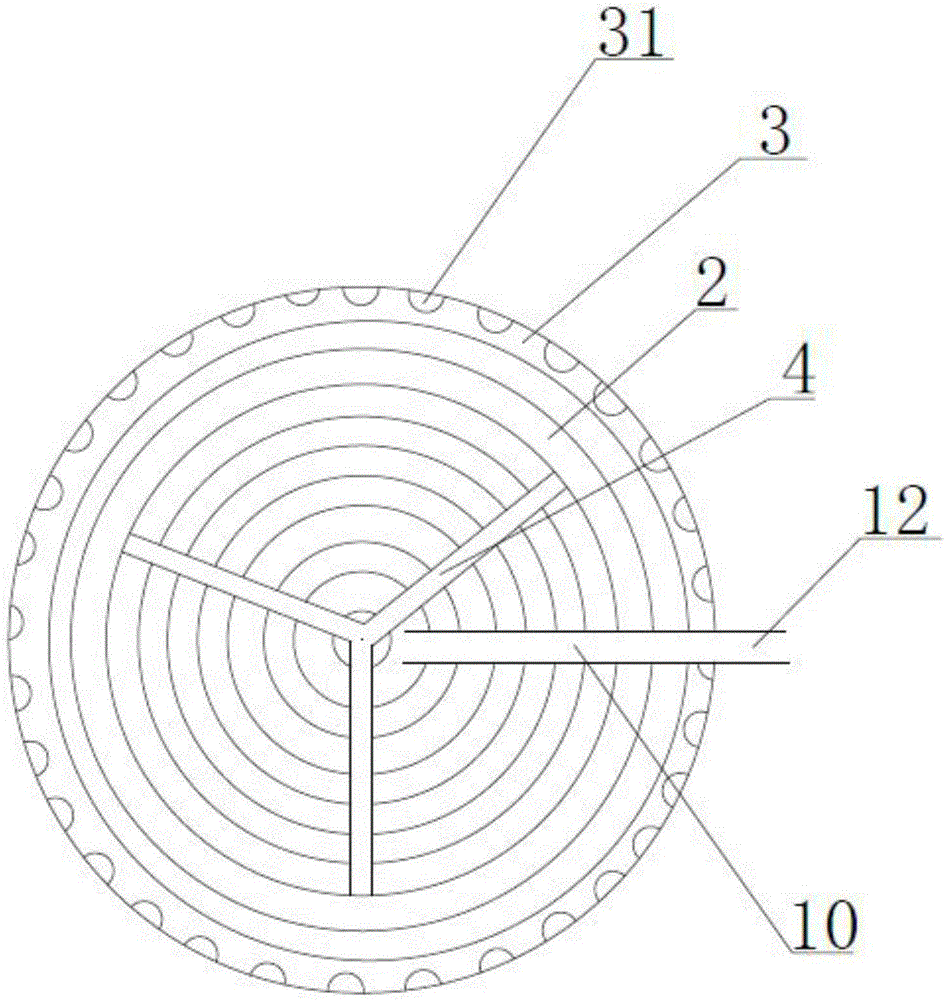

[0013] According to attached Figures 1 to 3 As described above, a fully automatic cleaning heat energy recovery device includes a barrel body, the barrel body is provided with a hot water inlet, a hot water outlet, a cold water inlet and a cold water outlet, and the barrel body is provided with a coiled incense bellows and a spiral type bellows, the incense-type bellows and the spiral bellows constitute an energy-saving inner core, the upper part of the energy-saving inner core is provided with a water guide plate 3, and the water guide plate is provided with a water guide hole, and the guide A 360° plane rotating nozzle is arranged above the water plate, and a 360° three-dimensional rotating cleaning nozzle is arranged in the barrel body. The lower part is connected with the barrel body, the cold water inlet is connected with the spiral bellows, the cold water outlet is connected with the coiled bellows, and the cold water inlet is also connected with the 360° plane rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com