Hybrid white light organic electroluminescence device

An electroluminescent device, white light technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of complex device structure, high process cost, and inapplicability of new materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

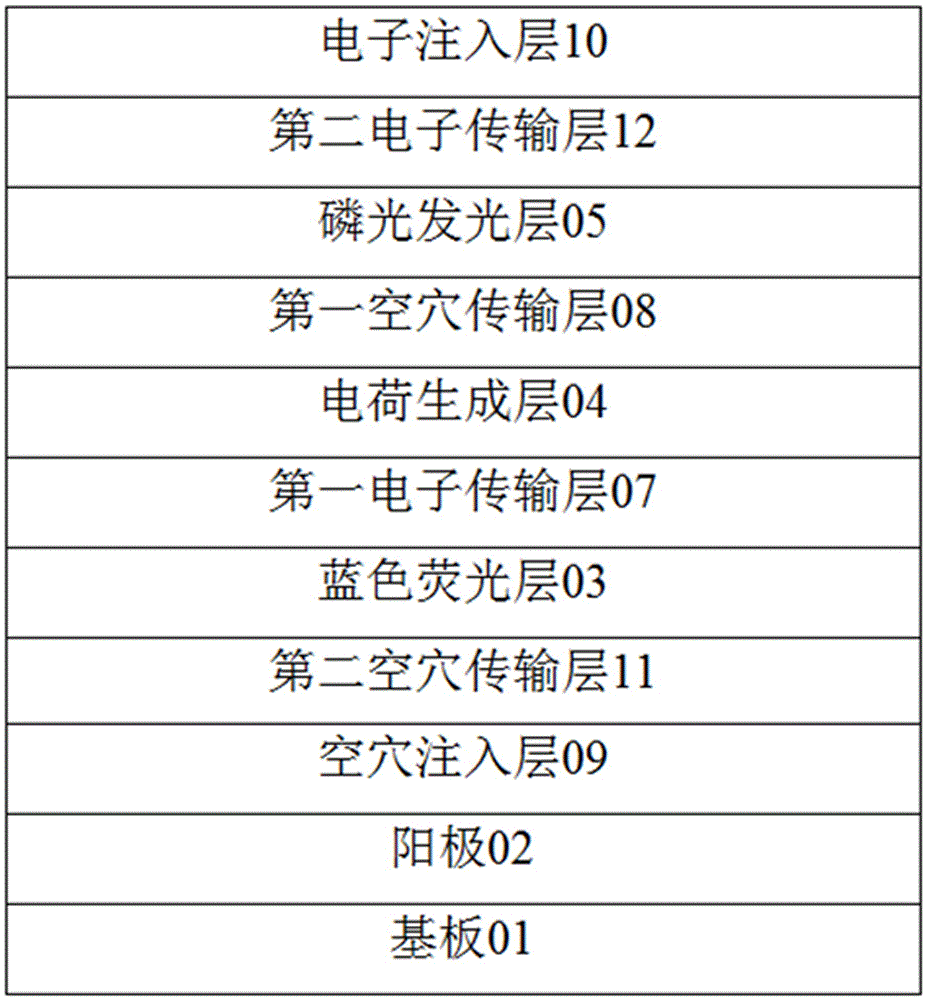

[0036] A hybrid white light organic electroluminescence device is provided with a substrate, an anode, a cathode and a functional layer between the anode and the cathode, the functional layer at least comprises a blue fluorescent layer and at least one layer of phosphorescence that forms complementary colors with blue light a light emitting layer and at least one charge generation layer. The hybrid white light organic electroluminescence device has at least one set of spaced structures, and the spaced structure refers to a structure in which the blue fluorescent layer and the phosphorescent light-emitting layer are separated by at least one charge generation layer.

[0037] In the hybrid white light organic electroluminescent device, the triplet energy level of at least one blue fluorescent layer is higher than the triplet energy level of at least one phosphorescent light-emitting layer.

[0038] In the hybrid white light organic electroluminescence device, the singlet exciton...

Embodiment 3

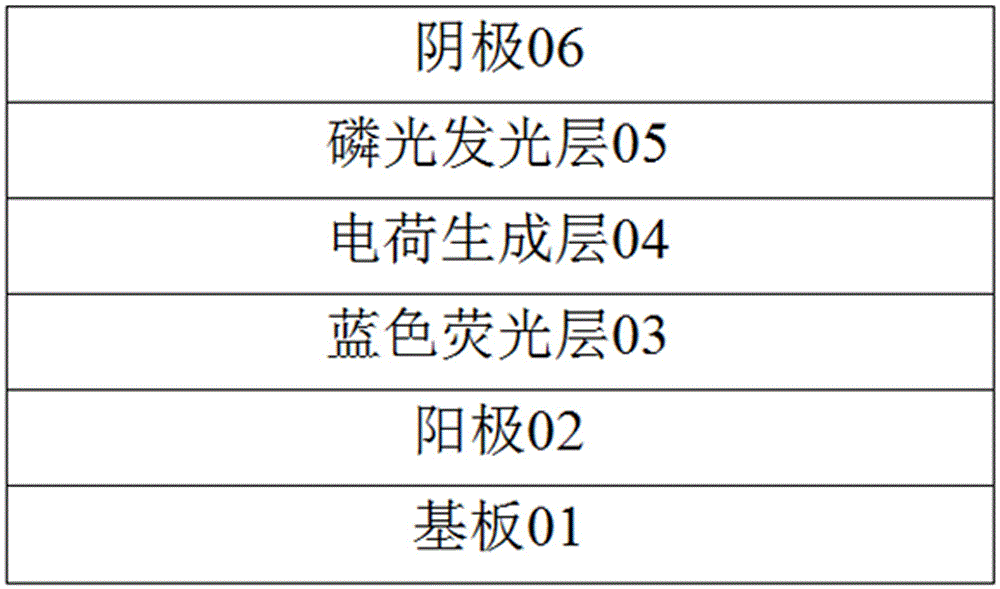

[0051] A hybrid white light organic electroluminescence device, as shown in FIG. 1, is provided with a substrate 01, an anode 02, a cathode 06 and a functional layer between the anode 02 and the cathode 06, the functional layer includes a blue fluorescent layer 03 , a phosphorescent light-emitting layer 05 and a charge generation layer 04 forming complementary colors with blue light. The hybrid white light organic electroluminescence device has a set of spaced structures, and in the spaced structures, the blue fluorescent layer 03 and the phosphorescent light-emitting layer 05 are separated by a charge generation layer 04 .

[0052] The triplet energy level of the blue fluorescent layer 03 is higher than that of the phosphorescent light-emitting layer 05 . In this hybrid white light organic electroluminescence device, the singlet excitons generated in the blue fluorescent layer 03 are captured and utilized by the blue light-emitting body, and the triplet excitons generated in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com