Furrowing and ridging machine for ridge culture of rape

A ridge machine and rapeseed technology, which is applied in the fields of tillage equipment, agricultural machinery and equipment, and application, can solve the problems of high operating power consumption, mud and grass entangled in the operating equipment, and non-finely fragmented soil blocks on the surface of the box, so as to improve the operation. Efficiency, reduce labor intensity, shorten the effect of process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

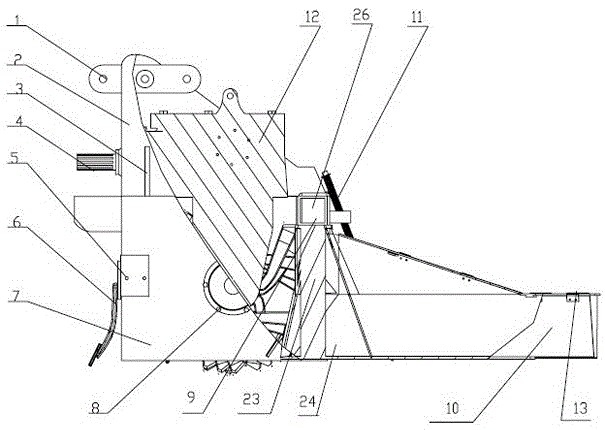

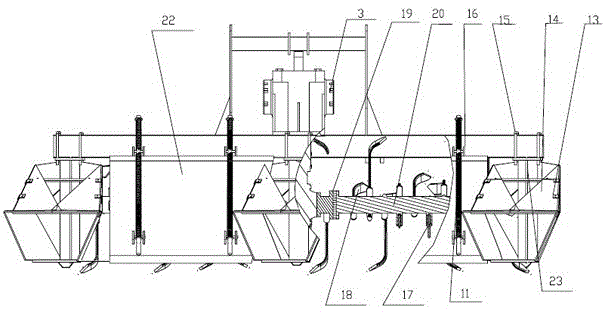

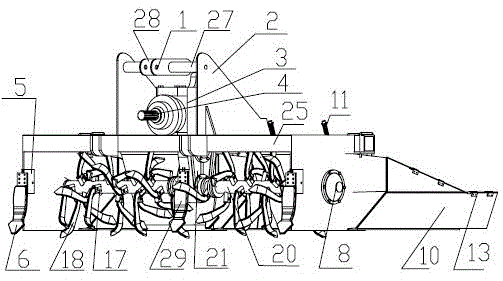

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as Figure 1 to Figure 5 As shown, the rapeseed ridge ditching and ridging machine of the present invention includes a transmission device installed on a box-shaped frame, a soil-entry fixing device, a rotary tillage device, a ditching device, a car surface finishing device, and a back-up output through the tractor. The work of the present invention is driven by power to complete the operation procedures such as soil rotary tillage, ditching and ridge formation, ridge forming and box surface finishing. The box-type frame includes frame front and rear beams 25, 26, and the two ends of the frame front and rear beams 25, 26 are provided with frame side plates 7, thereby forming a semi-closed box structure. The semi-enclosed box structure can ensure that all the soil entering the rotary tillage device moves within the range d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com