Dispersion system reaction device

A technology of dispersion system and reaction device, applied in the directions of transportation and packaging, dissolving, mixer, etc., can solve the problem that mechanical stirring cannot meet the requirements of powder dispersibility, avoid agglomeration, avoid agglomeration deposition, and achieve good dispersion uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

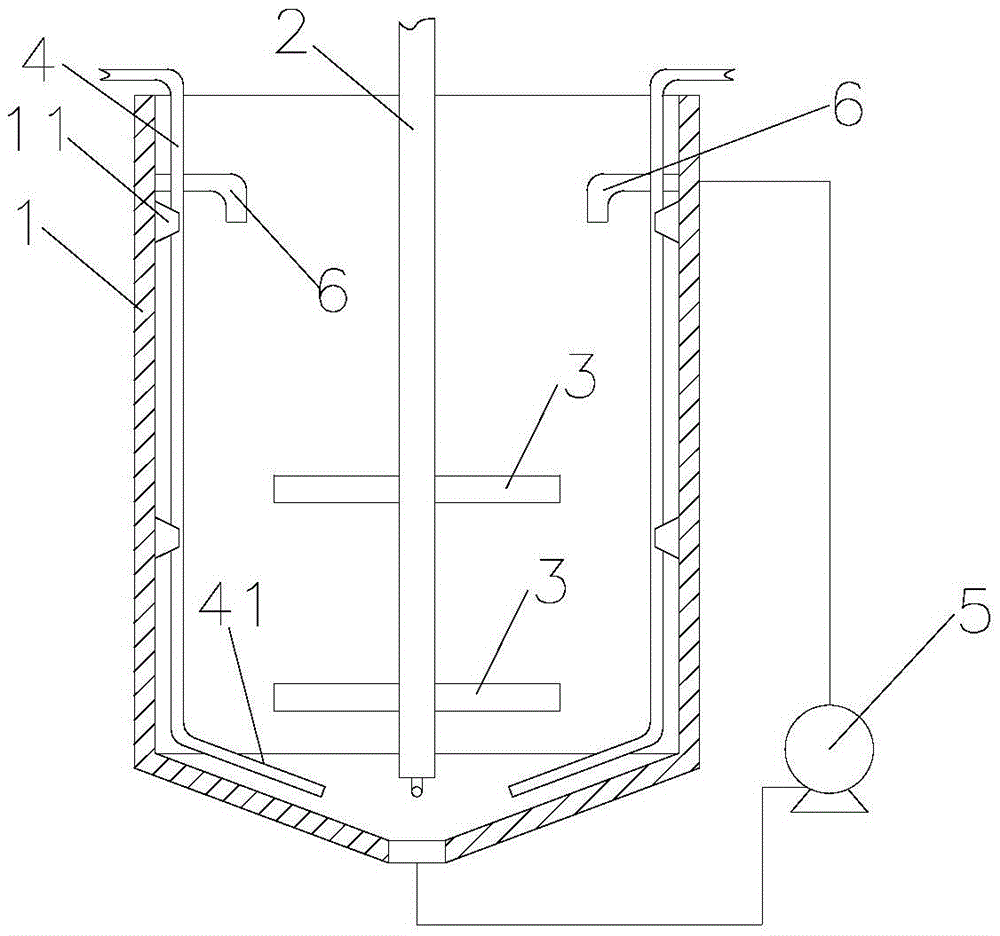

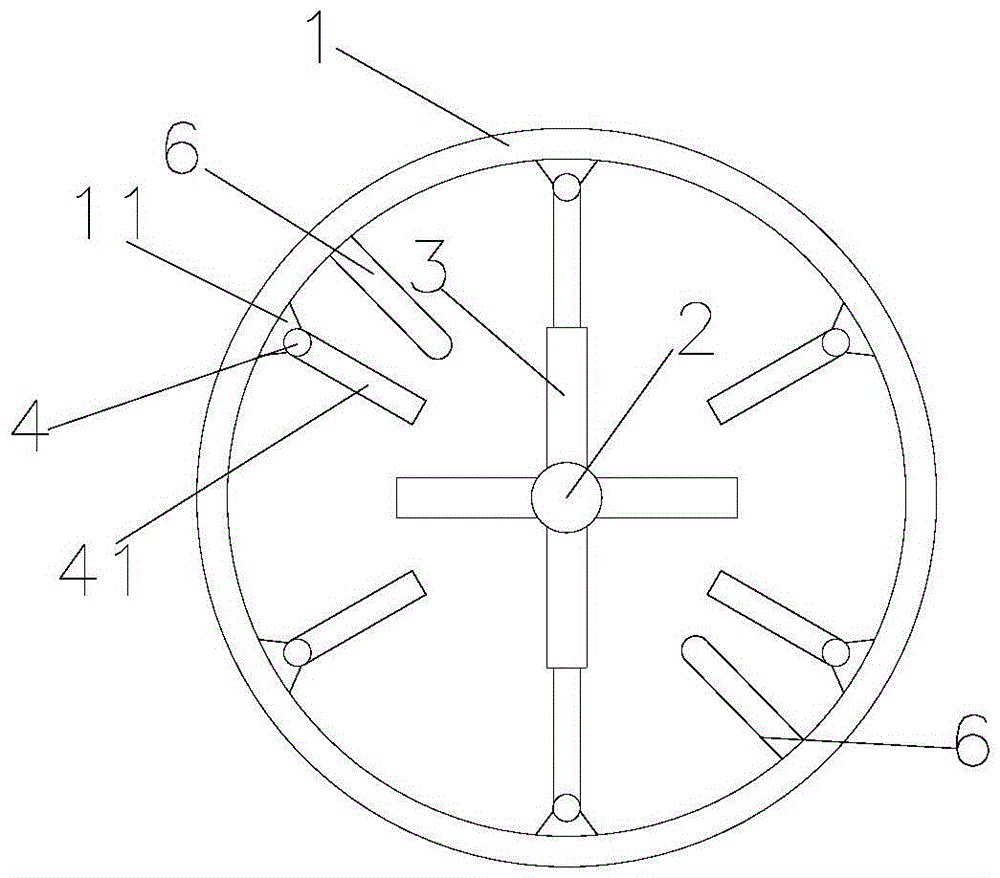

[0019] Such as figure 1 with 2 As shown, a dispersion system reaction device includes a kettle body 1, a mechanical stirring device, an air stirring device and a diaphragm pump 5; the mechanical stirring device is arranged in the kettle body 1 and includes a stirring shaft 2 and two stirring Paddle 3, the two stirring paddles 3 are respectively installed at different height positions of the stirring shaft 2;

[0020] The air stirring device includes 6 air pipes 4 evenly arranged near the inner wall of the kettle body 1, the air pipes 4 are arranged along the height direction of the kettle body 1, and several air holes are opened on the air pipe 4, and the air holes face The inner wall of the kettle body 1 is opened; the bottom of the air pipe 4 has a bent end 41 adapted to the tapered bottom of the kettle body 1, and the bent end 41 is also provided with air holes, and the air holes on the bent end 41 It opens towards the bottom of the kettle body 1, and the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com