Crusher feeding control method and control device

A crusher and feeding technology, applied in grain processing and other directions, can solve problems such as unhealthy health, downtime for maintenance, crusher blockage, etc., to ensure smoothness, improve production efficiency, and reduce material blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

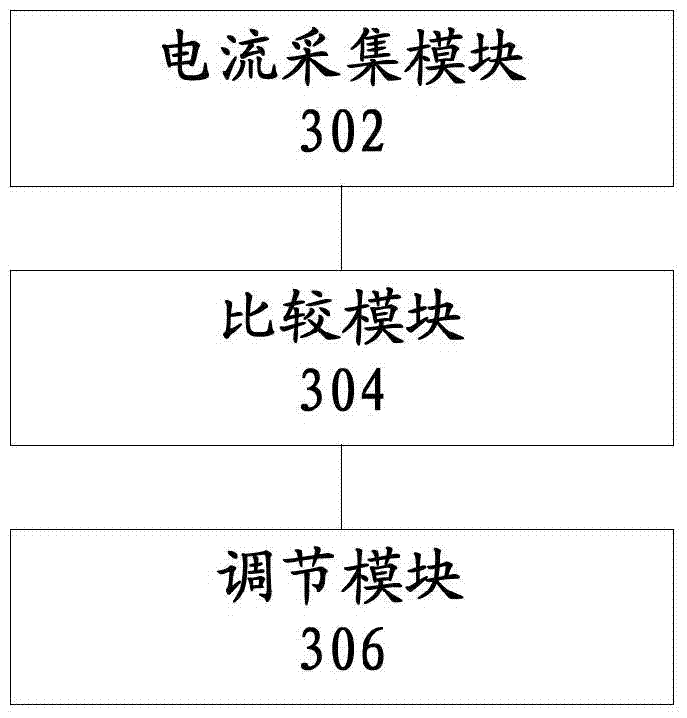

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0023] The inventors found that the current of the crusher changes continuously with the amount of materials. Generally speaking, the more materials in the crusher, the greater the current, and the less the materials, the smaller the current. Therefore, a scheme to adjust the feeding speed according to the current change of the crusher is proposed.

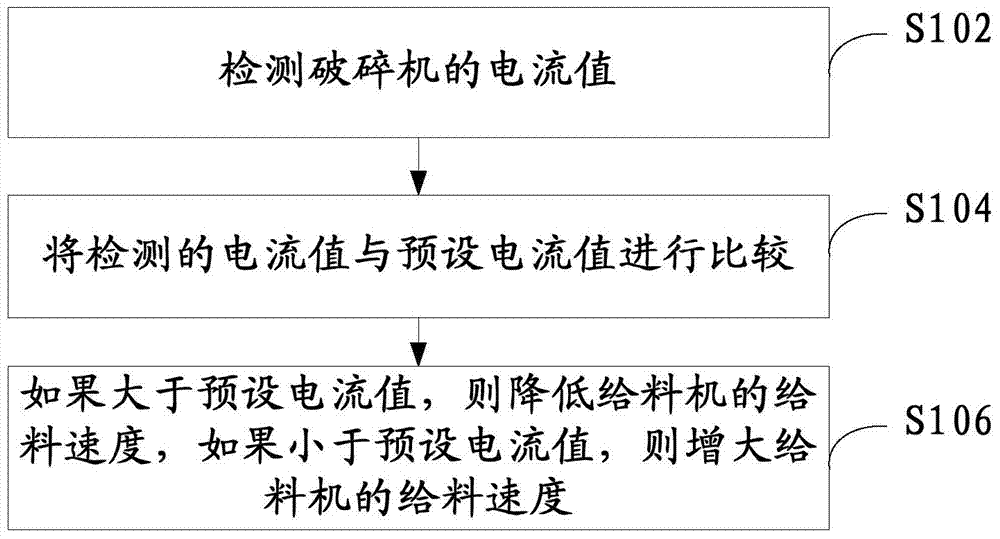

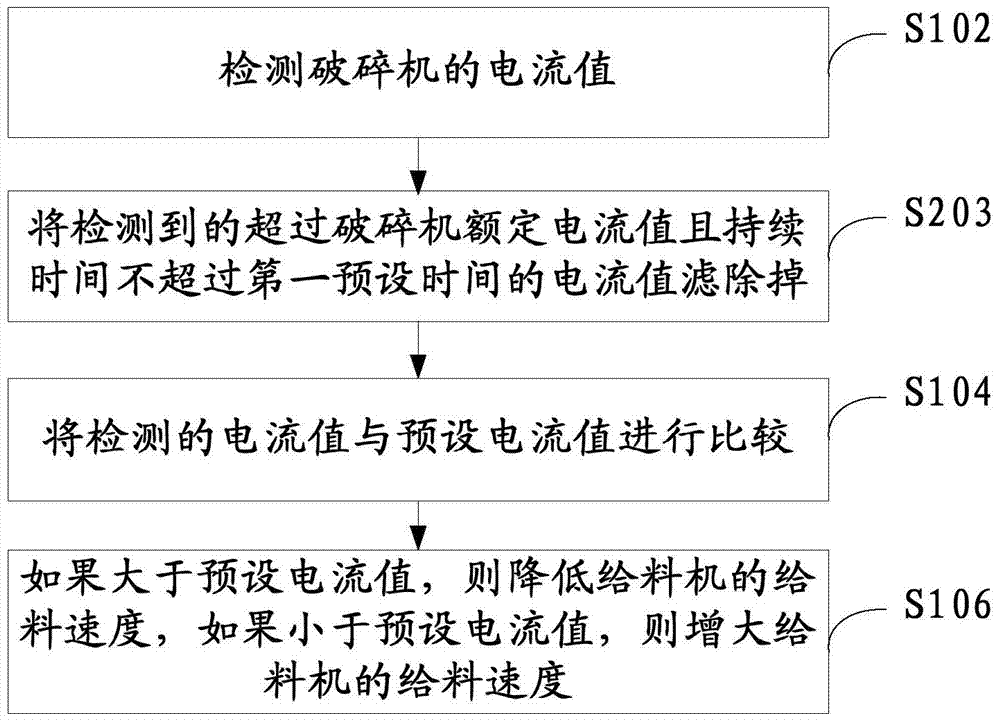

[0024] figure 1 It is a schematic flow chart of an embodiment of the control method for crusher feeding in the present invention.

[0025] Such as figure 1 As shown, the method of the present embodiment includes:

[0026] Step S102, detecting the current value of the crusher.

[0027] An exemplary detection method is to pass the current of the main shaft motor of the crusher through the current transformer, then through the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com