Fillet weld tracking system and method based on ultrasonic swing scanning

A tracking system and ultrasonic technology, used in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as electromagnetic field interference, harm to workers' health, tracking instability, etc., to improve accuracy, adaptive ability, and good statistical properties. , the effect of reducing the data sample space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

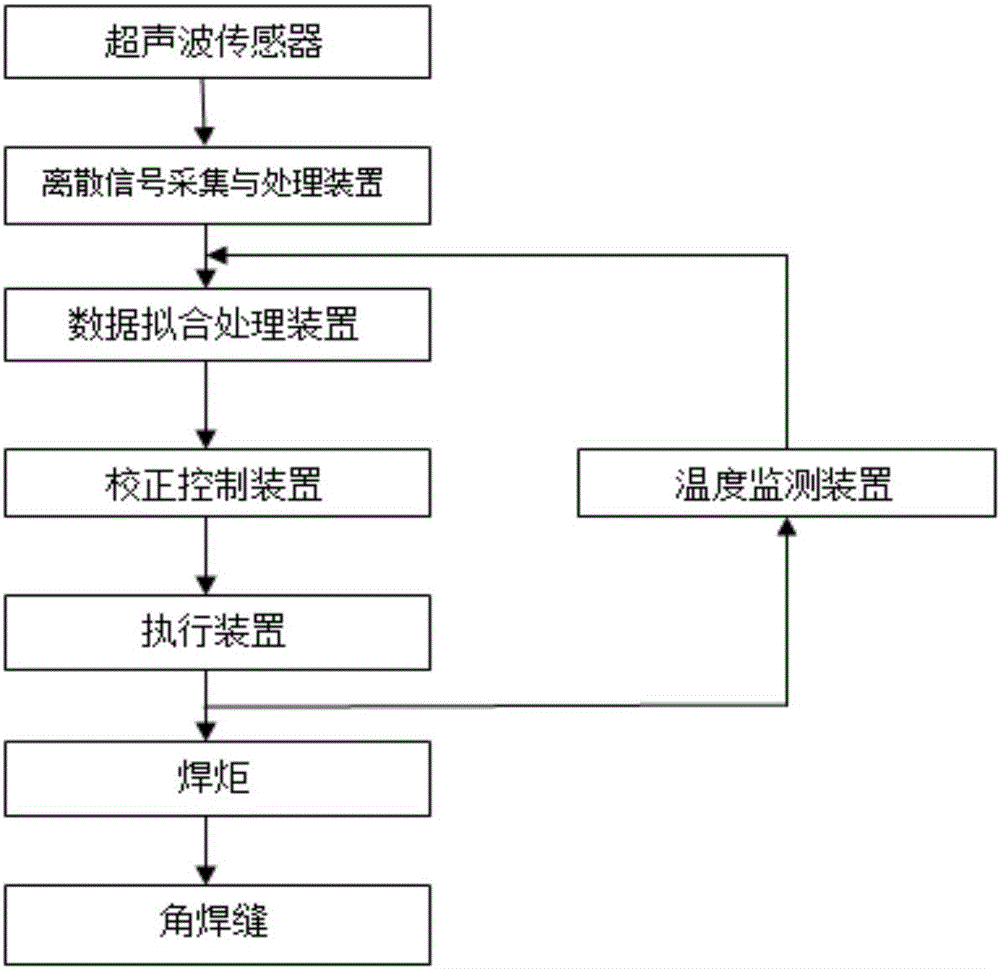

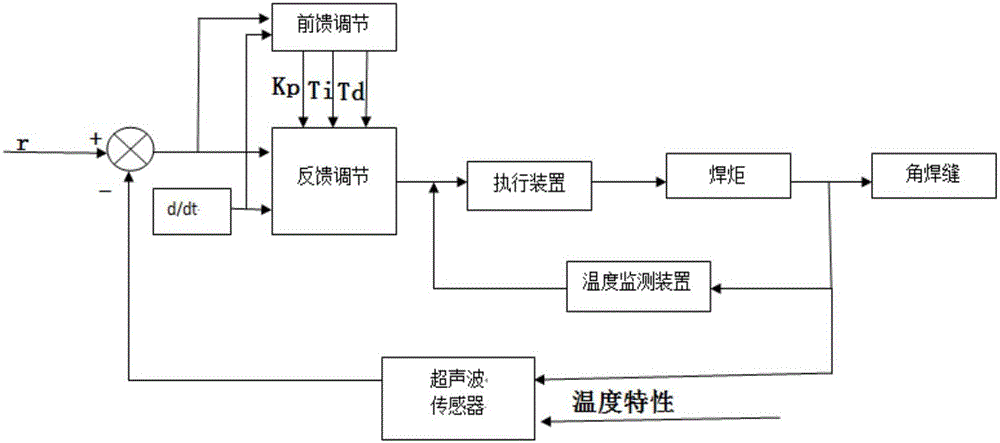

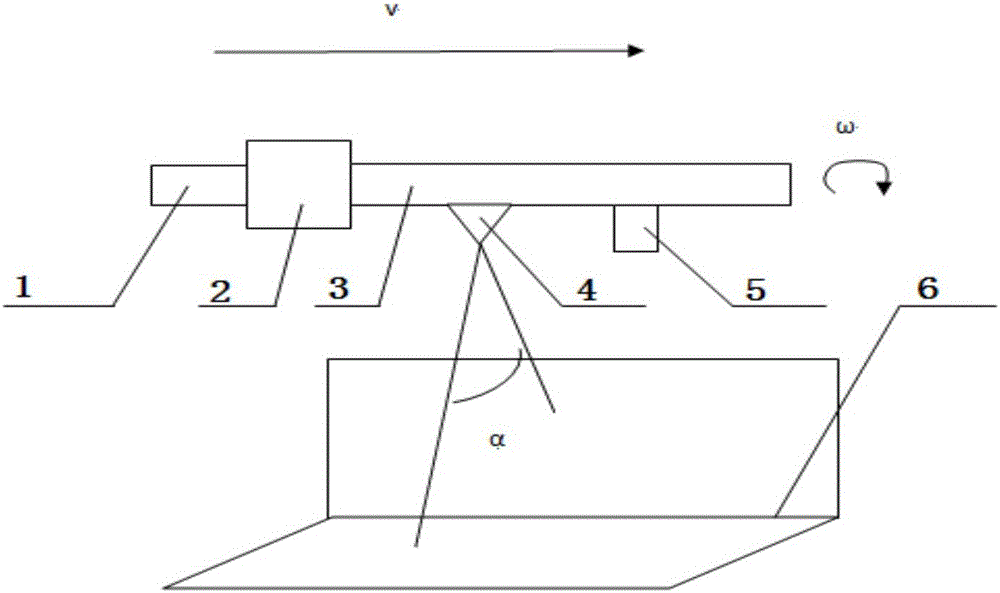

[0016] Embodiment 1 The present invention discloses a fillet weld tracking system and method based on ultrasonic swing scanning, which includes an ultrasonic sensor, a discrete signal acquisition and processing device, a data fitting processing device, a correction control device, a temperature monitoring device, and an execution device , welding torch, welding power supply, etc. The invention uses the scanning signal output by the ultrasonic sensor, combined with the temperature characteristics of the temperature monitoring device, the data fitting processor adopts the weighted least square method to identify the center of the fillet weld, and the correction control device adopts the intelligent adjustment of feedforward and feedback to correct the deviation , the actuator drives the welding torch to track the fillet weld according to the correction characteristics, see Figure 1-Figure 4 .

[0017] The invention discloses a fillet weld tracking system and method based on ul...

Embodiment 2

[0034] Embodiment 2 The present invention can also be applied to fillet weld tracking at any angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com