Edge grinding device for special-shaped glass remote control processing production line and operation method of edge grinding device

A technology for remote control processing and special-shaped glass, which is applied in grinding/polishing safety devices, metal processing equipment, machine tools suitable for grinding workpiece edges, etc. The effect of high environmental safety factor, improved edging efficiency and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

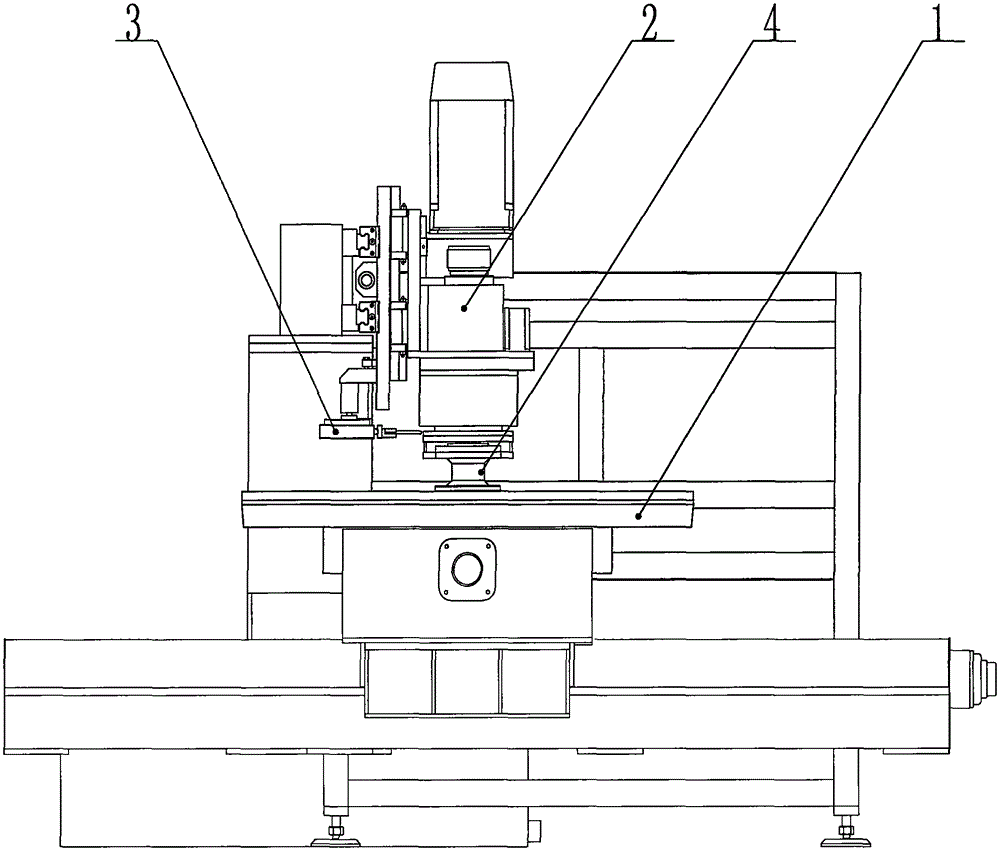

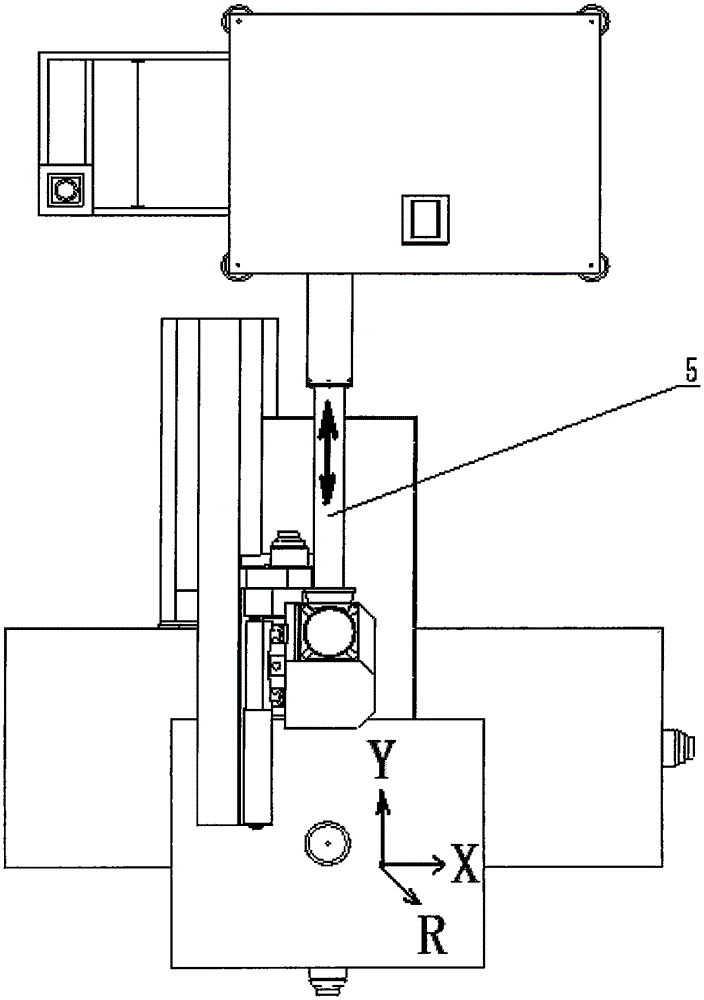

[0038] As shown in the figure, an edging device for a special-shaped glass remote processing production line is composed of: edging mobile worktable 1, water-cooled hidden grinding head device 2, automatic grinding wheel device 3, vacuum suction cup 4, cooling circulating water device hydraulic pressure Consisting of telescopic tube 5; one end of hydraulic telescopic tube 5 for cooling circulating water device is equipped with water-cooled and hidden grinding head device 2, and one side of water-cooled and hidden grinding head device 2 is equipped with automatic dressing grinding wheel device 3, and the bottom of automatic dressing grinding wheel device 3 is equipped with edging mobile work Table 1, the middle part of the edging mobile table 1 is provided with a vacuum suction cup 4.

Embodiment 2

[0040] As shown in the figure, the edging mobile workbench 1 is rectangular or circular, and is arranged on one side below the water-cooled hidden grinding head device 2 and the automatic dressing wheel device 3 .

Embodiment 3

[0042] As shown in the figure, the vacuum chuck 4 is arranged on one side below the water-cooled hidden grinding head device 2 and the automatic dressing grinding wheel device 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com