Glue cutter unit with interchangeable inserts

A knife device and cutting knife technology, applied in metal processing and other directions, can solve the problems of easy sliding, transfer, unstable transportation, affecting the use of the cutting knife, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

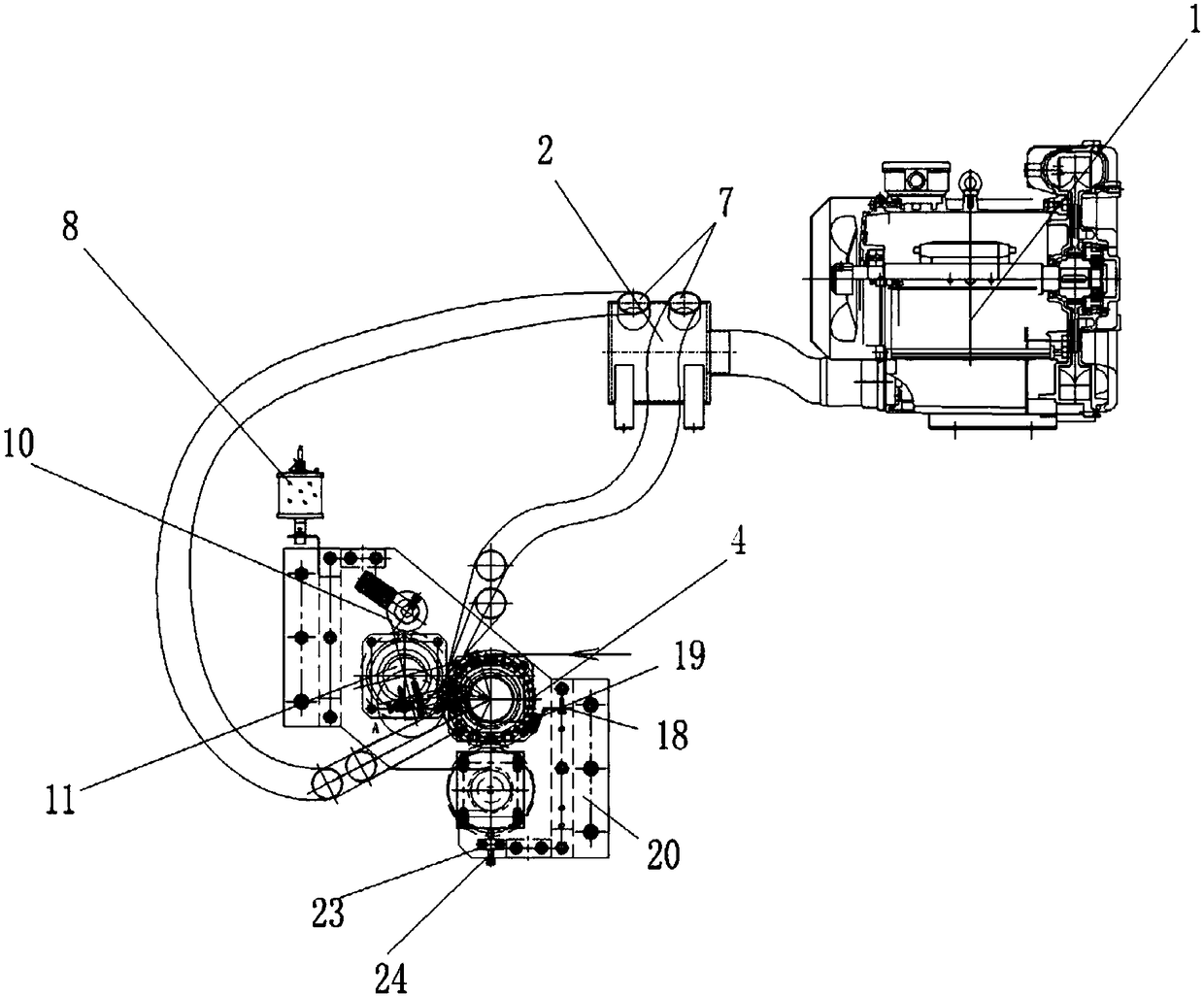

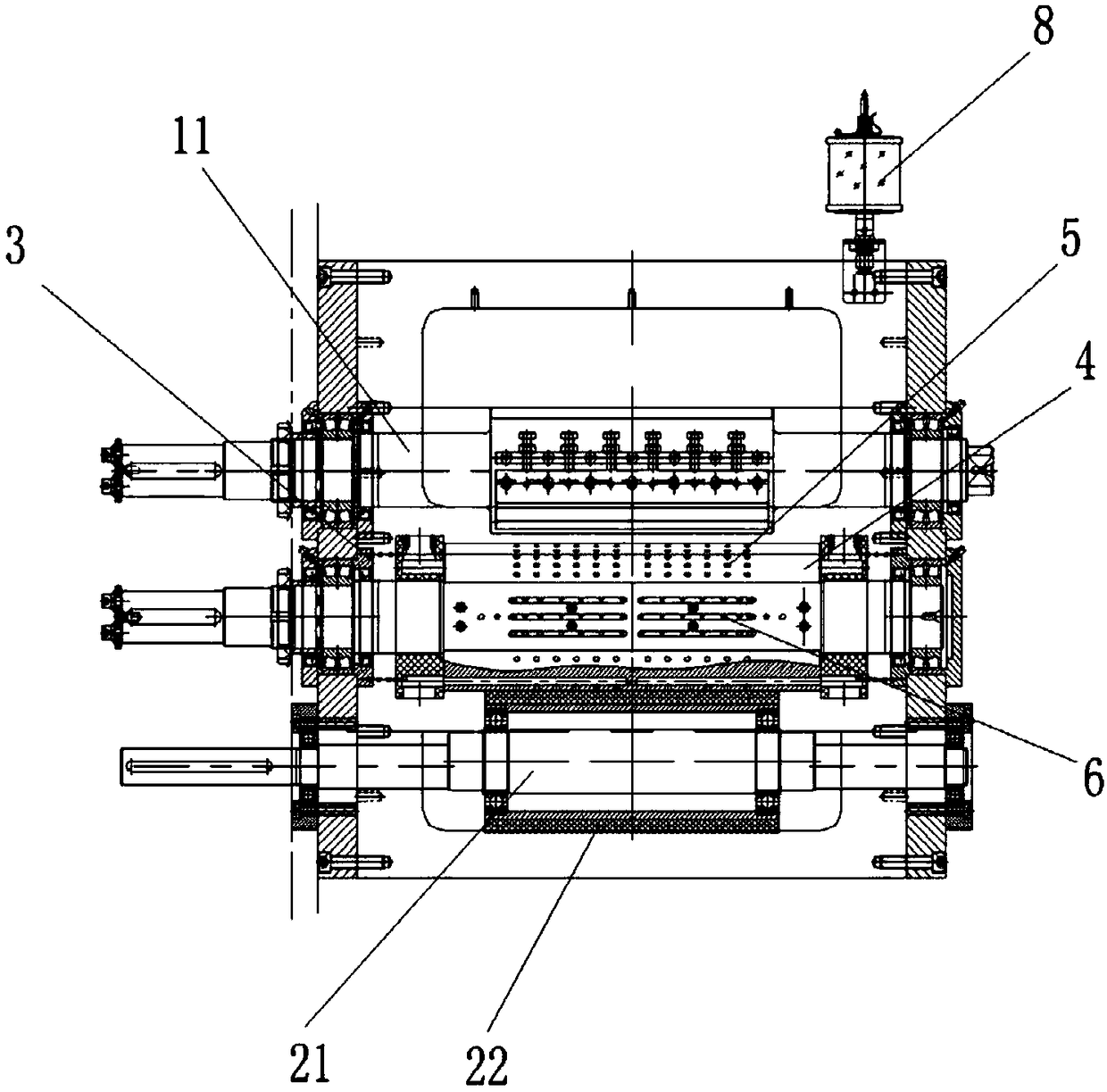

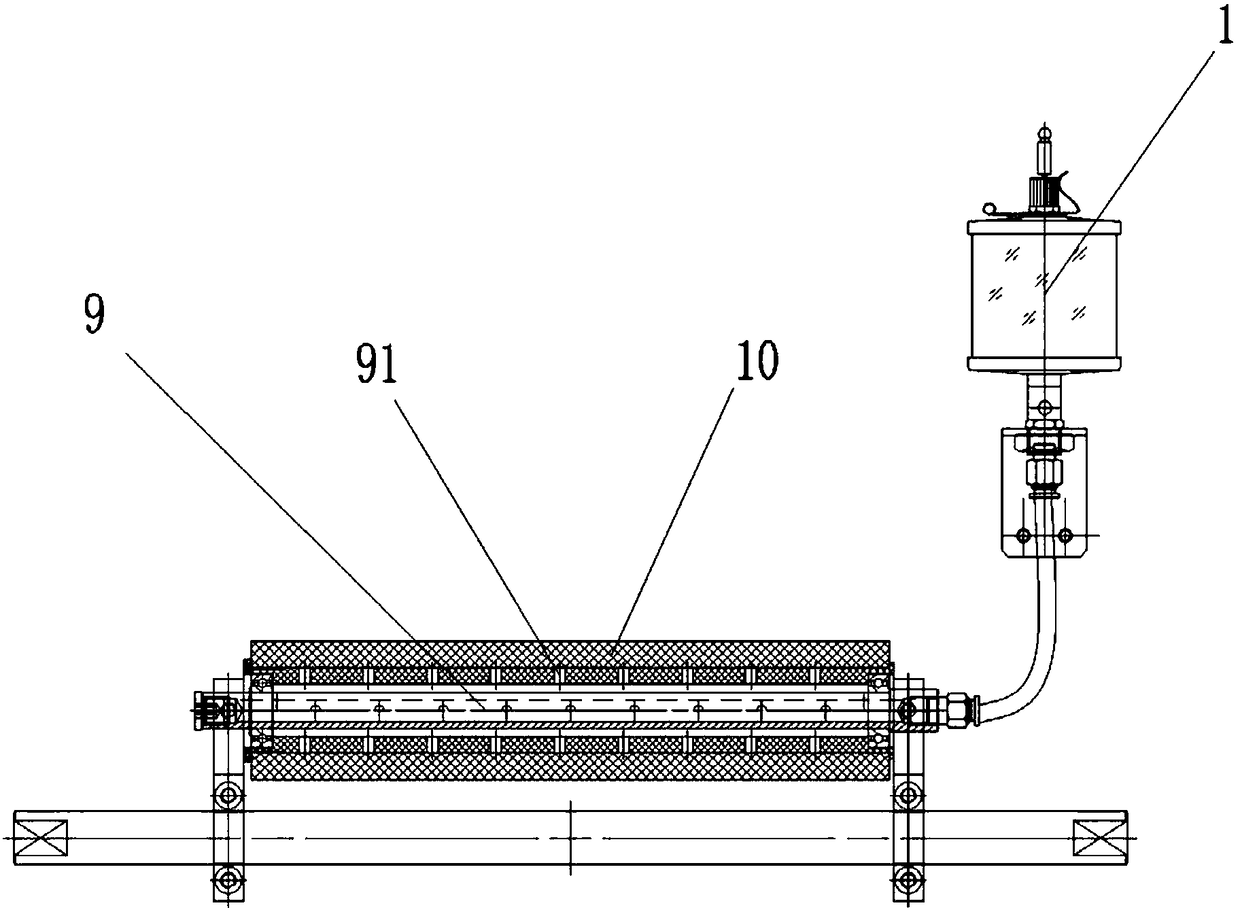

[0021] reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the adhesive cutter device with interchangeable inserts of the present invention includes a cutter system, a bottom knife roll system, a negative pressure system, and a cam bonding system. The negative pressure system includes a vortex air pump 1, a negative pressure box 2, and a negative pressure system. The pressure plate 3, the bottom knife roller system includes a bottom roller 4, on the bottom roller 4 there are two sets of negative pressure holes 5 symmetrical to the bottom roller 4, the bottom roller 4 between the two sets of negative pressure holes 5 forms a positioning surface, A set of raised positioning posts 6 are provided on the positioning surface. The negative pressure hole 5 is connected with the negative pressure plate 3. The negative pressure box 2 is provided with two negative pressure ports 7, and the negative pressure port 7 and the negative pressure plate 3 pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com