A rolling hot press, a veneer lengthening system and a veneer lengthening method

A hot press and veneer technology, applied in the field of plywood manufacturing, can solve the problems of difficult precise control of heat source position and time, labor and time consumption, complicated manual operation, etc., to save manpower, avoid time waste, and shorten working hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

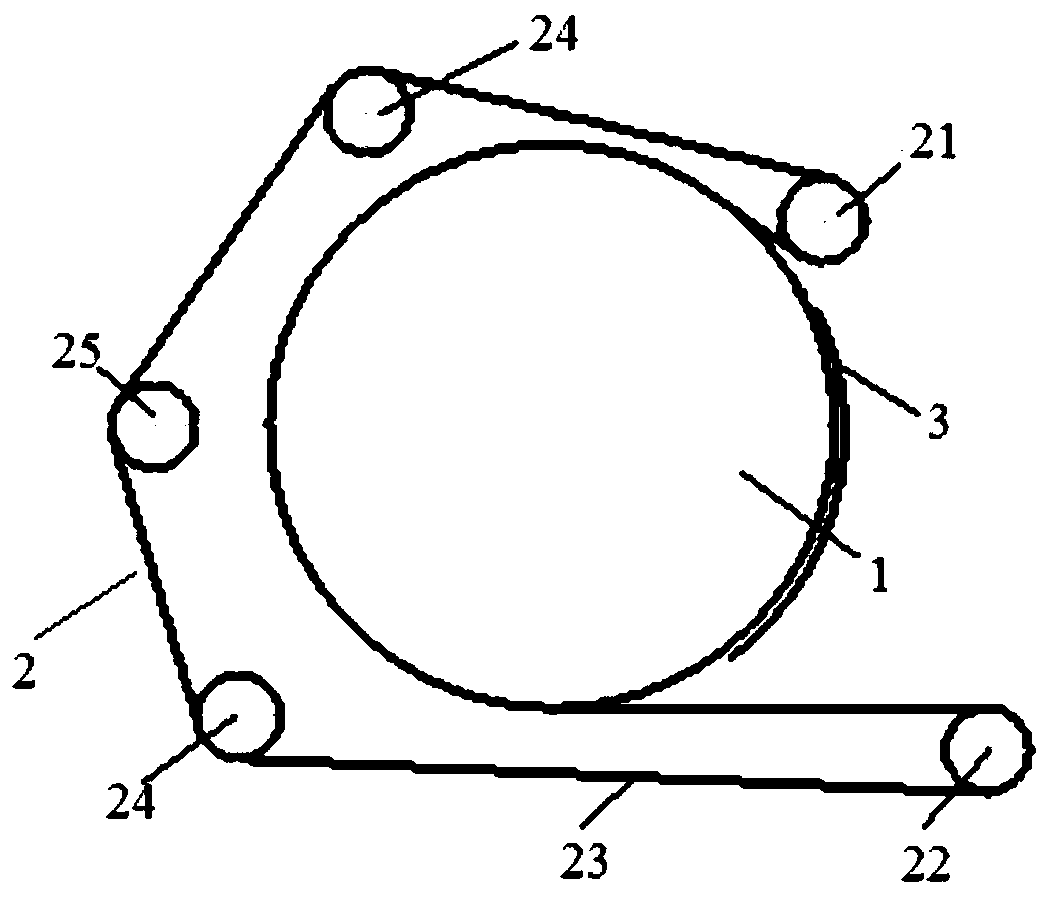

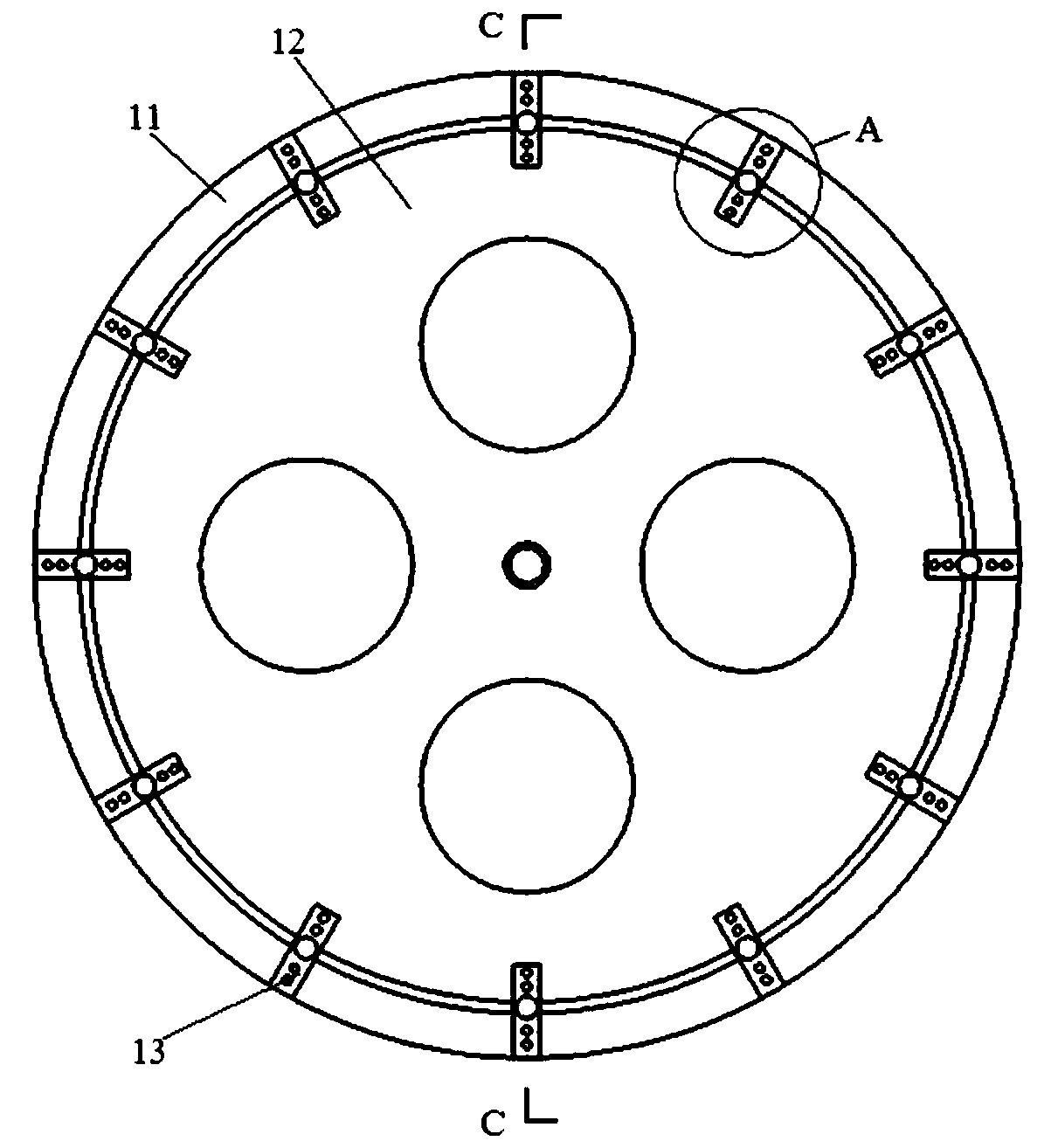

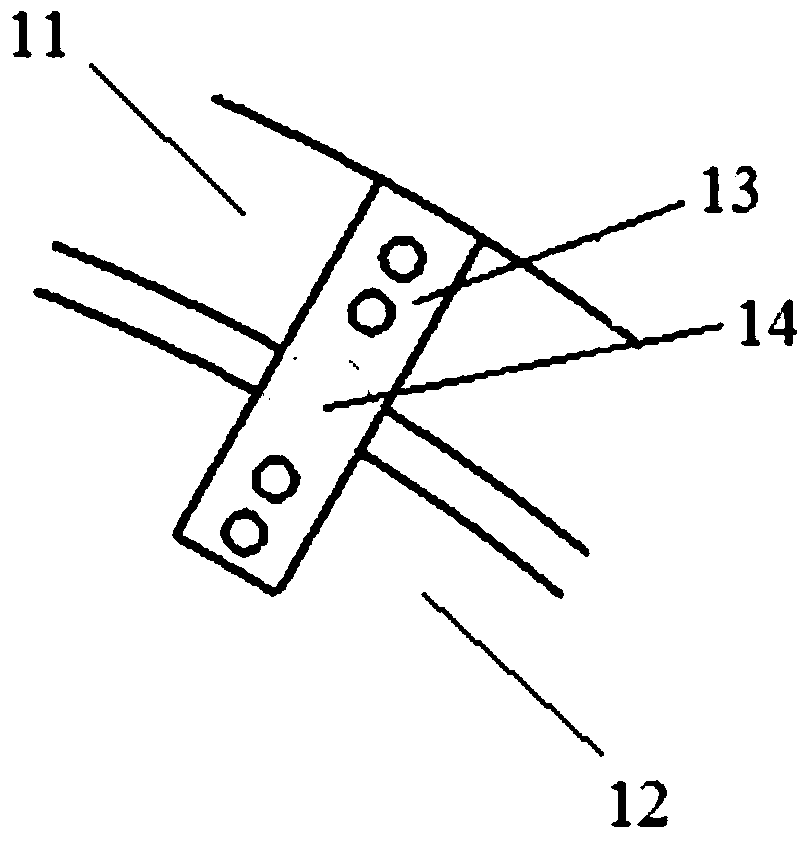

[0039] like figure 1As shown, the roll pressing heat press provided by the first embodiment of the present invention includes a hot pressing roll 1 and a transmission device 2. The transmission device 2 includes a driving roll 21 and a driven roll 22, and the driven roll 22 is located at the input end of the veneer, The driving roller 21 is located at the output end of the veneer, the driving roller 21 and the driven roller 22 are connected by a loop-closed rolling belt 23, the hot pressing roller 1 is located between the driving roller 21 and the driven roller 22, and the rolling belt 23 is The outer side is in contact with the outer circumferential surface of the hot pressing roller 1 to form a hot pressing section, so as to drive the hot pressing roller 1 to rotate in the circumferential direction, and the veneer is hot pressed in the hot pressing section.

[0040] The driving roller of the roller pressing machine of the present invention is connected with the driven roller...

Embodiment 2

[0048] like Image 6 As shown in the figure, the veneer lengthening system provided in the second embodiment of the present invention includes a first conveyor belt 4, a second conveyor belt 5, and the roller pressing heat press as described in the above-mentioned first embodiment. The first conveyor belt 4 is arranged on the The input end of the veneer of the roll pressing machine, the second conveyor belt 5 is arranged at the output end of the veneer of the roll pressing machine, and the first conveyor belt 4 includes the synchronous parallel upper and lower inclined grinding surface conveyor belts. There is an upper narrow belt sander above the side of the upper oblique grinding surface conveyor belt close to the lower oblique grinding surface conveyor belt to obliquely grind the first veneer to form an upward slope; the lower oblique grinding surface conveyor belt A lower narrow belt sander is arranged below the side of the conveyor belt close to the upper oblique grinding...

Embodiment 3

[0053] The third embodiment of the present invention provides a single-board extension method based on the single-board extension system in the second embodiment, including the following steps:

[0054] S1. Place the first veneer and the second veneer on the upper and lower oblique grinding surface conveyor belts along the grain, respectively;

[0055] S2. The upper narrow-band sander obliquely grinds the end of the first veneer close to the second veneer to form an upward slope, and the lower narrow-band sander obliquely grinds the end of the second veneer close to the first veneer to form a downward slope. bevel;

[0056] S3. The pressure glue injector applies glue to the slope of the first veneer;

[0057] S4. The adsorption conveyor belt picks up the second veneer and runs synchronously to the input end of the veneer with the upper inclined grinding surface conveyor belt; the servo cylinder pushes the adsorption conveyor belt to move laterally to the corresponding top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com