Process for once extrusion molding to make sheath

A production process and extrusion molding technology, which is applied in the field of one-time extrusion sheath production technology, can solve problems such as easy to fall off and affect the performance of wiping rain, so as to reduce the scrap rate, the sheath has a good texture, and the cost is easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

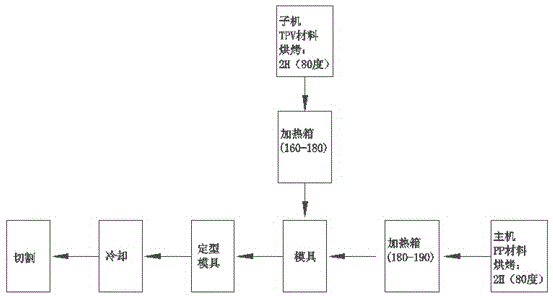

[0015] This process method includes steps;

[0016] 1) Ingredients, thermoplastic rubber TPV and polypropylene PP;

[0017] 2) Extrusion, using the main machine and the sub-machine, put the polypropylene PP in the main machine, bake 2 hours at 80 degrees, put the thermoplastic rubber TPV material in the sub machine, bake 2 hours, 80 degrees, the main machine The polypropylene PP inside is transferred to the heating barrel, the polypropylene PP temperature is heated to 180-190 degrees, the thermoplastic rubber TPV in the slave machine is transferred to the heating barrel, the thermoplastic rubber TPV is heated to 160-180 degrees, and the two types are heated after the heating is completed. The material is conveyed into the mold, and then conveyed to the forming mold through the mold for finalization;

[0018] 3) Shaping and cooling to solidify the shape;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com