Electronic device, physical quantity sensor, pressure sensor and altimeter

A technology of electronic devices and sensor elements, applied in the field of moving objects, can solve problems such as cracks on the top

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

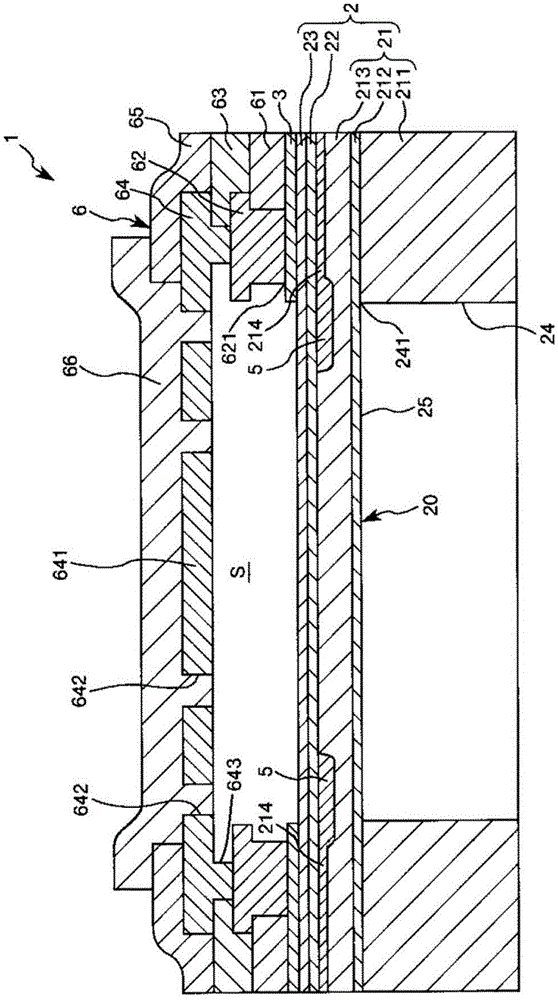

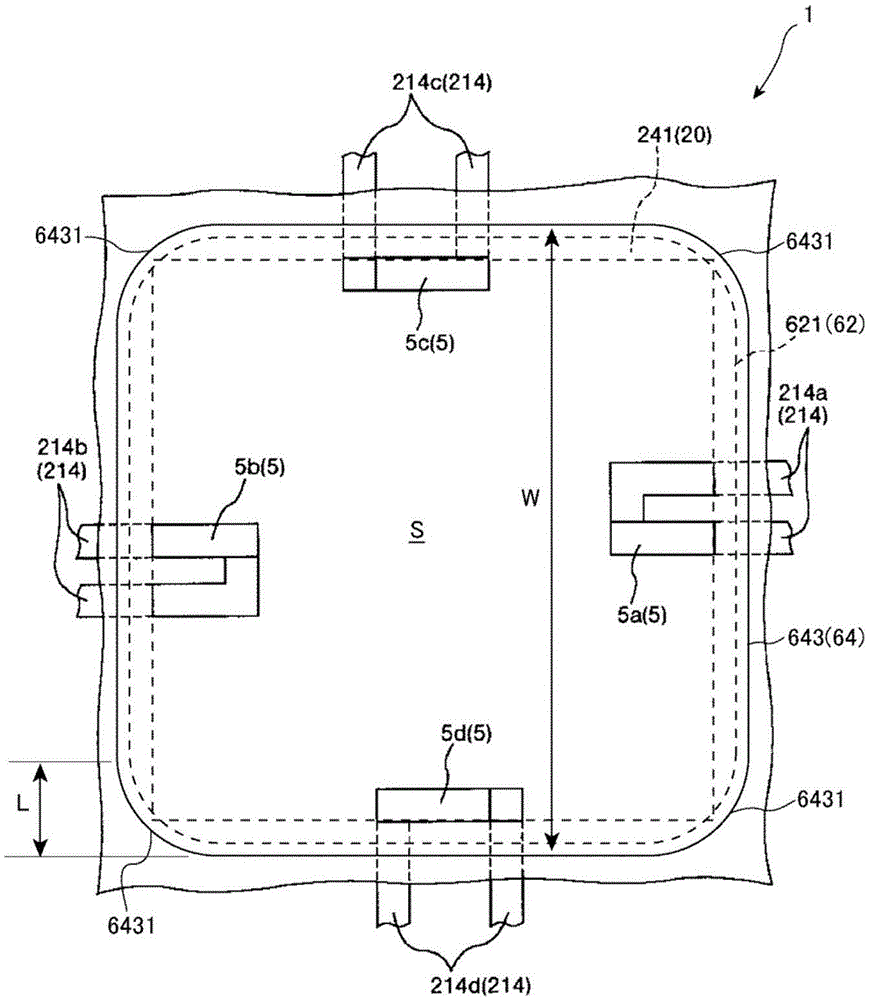

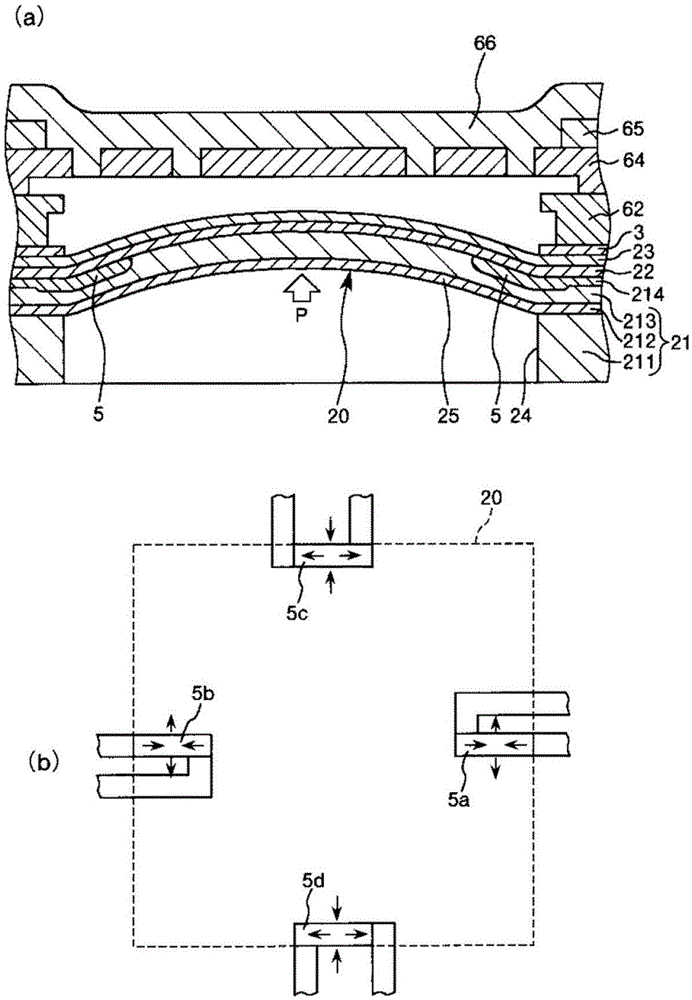

[0061] figure 1 It is a sectional view showing the physical quantity sensor according to the first embodiment of the present invention, figure 2 to represent figure 1 It is a plan view of the arrangement of piezoresistive elements (sensor elements) and walls of the shown physical quantity sensor. image 3 for the figure 1 A diagram illustrating the role of the physical quantity sensor shown, image 3 (a) is a sectional view showing a pressurized state, image 3 (b) is a plan view showing a pressurized state. In addition, in the following, for the convenience of explanation, the figure 1 The upper side is called "upper" and the lower side is called "lower".

[0062] figure 1The shown physical quantity sensor 1 includes: a substrate 2 having a diaphragm portion 20; a plurality of piezoresistive elements 5 (sensor elements) as functional elements arranged on the diaphragm portion 20; chamber) stacked structure 6; and the intermediate layer 3 arranged between the substrat...

no. 2 approach

[0138] Next, a second embodiment of the present invention will be described.

[0139] Figure 6 It is a plan view showing the arrangement of piezoresistive elements (sensor elements) and wall portions of the physical quantity sensor according to the second embodiment of the present invention.

[0140] Hereinafter, although the second embodiment of the present invention will be described, the differences from the above-mentioned embodiment will be mainly described, and the description of the same matters will be omitted.

[0141] This embodiment is the same as the first embodiment described above except that the shapes of the wall and the top are different.

[0142] Figure 6 The illustrated physical quantity sensor 1A includes wiring layers 62A and 64A, and the covering layer (not shown) of the wiring layer 64A constitutes a "top". The structure formed by the layer 64A constitutes a "wall".

[0143] Furthermore, the inner peripheral edge 643A of the end portion of the wall...

no. 3 approach

[0149] Next, a third embodiment of the present invention will be described.

[0150] Figure 7 It is a plan view showing the arrangement of piezoresistive elements (sensor elements) and wall portions of the physical quantity sensor according to the third embodiment of the present invention.

[0151] Hereinafter, although the third embodiment of the present invention will be described, the differences from the above-mentioned embodiment will be mainly described, and the description of the same matters will be omitted.

[0152] This embodiment is the same as the first embodiment described above except that the shapes of the wall and the top are different.

[0153] Figure 7 The illustrated physical quantity sensor 1B includes wiring layers 62B and 64B, and the covering layer (not shown) of the wiring layer 64B constitutes a "top". The structure formed by 64B constitutes a "wall".

[0154] In addition, the inner peripheral edge 643B of the end portion of the wall portion oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com