Ultralow loss limit type Mgn+1TinO3n+1 microwave ceramic and making method thereof

A microwave ceramic, extreme technology, applied in the field of information functional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of Mg 3 Ti 2 o 7 ceramic samples;

[0019] Its preparation method comprises the following steps:

[0020] (1) Synthesis of Mg 3 Ti 2 o 7 Powder: MgO:TiO according to the raw material 2 =3:2 molar ratio mixing, ball milling the resulting mixed powder for 24 hours, drying through a 100-mesh sieve, pre-calcining at 1100°C for 2 hours, and ball-milling the pre-calcined powder for 12 hours Pass through 200 sieves to obtain Mg 3 Ti 2 o 7 Synthetic powder.

[0021] (2) Compression molding: the Mg obtained in step (1) 3 Ti 2 o 7 Add 5wt% polyvinyl alcohol to the ceramic material, mix evenly, grind it finely after drying, and press it into a cylindrical green body on a molding machine;

[0022] (3) Sintering: Sinter the cylindrical green body obtained in step (2) at 1360°C for 4 hours to form porcelain, and obtain ultra-low loss limit-like Mg3 Ti 2 o 7 microwave ceramics.

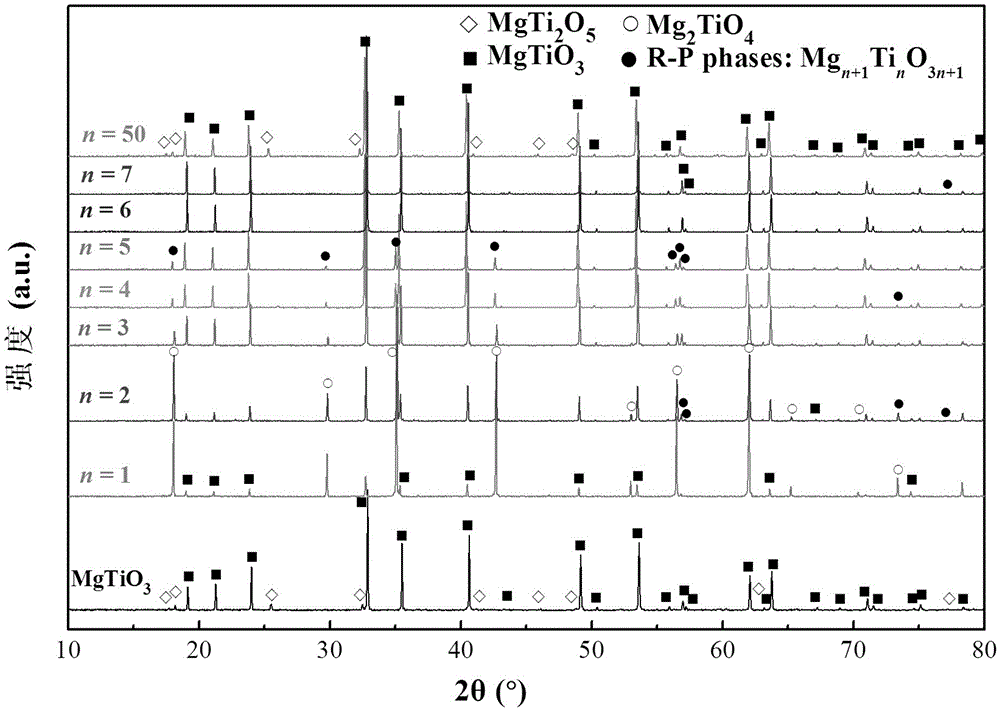

[0023] Analysis of Mg by XRD diffraction pattern 3 Ti 2 o 7 Phase, determi...

Embodiment 2

[0025] Preparation of Mg 4 Ti 3 o 10 ceramic samples;

[0026] Its preparation method, except according to the raw material with MgO:TiO 2 =4:3 molar ratio mixing and sintering temperature is 1340 ℃, other steps are the same as embodiment 1.

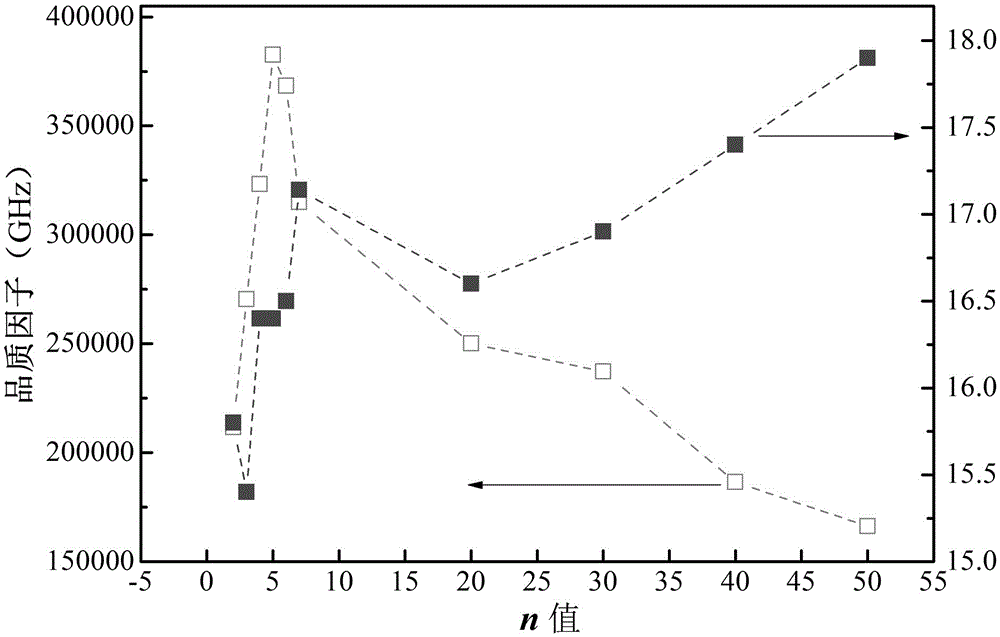

[0027] Performance tests show that: sintered at 1340°C for 4 hours, its dielectric constant ε r is 15.4, the resonant frequency temperature coefficient τ f -56.2ppm / ℃, Q×f value is 270,400GHz(f 0 =7.677GHz).

Embodiment 3

[0029] Preparation of Mg 5 Ti 4 o 13 ceramic samples;

[0030] Its preparation method, except according to the raw material with MgO:TiO 2 =5:4 molar ratio mixing, all the other steps are with embodiment 1.

[0031] The performance test shows that when sintered at 1360°C for 4 hours, its dielectric constant ε r is 16.4, the resonant frequency temperature coefficient τ f -60.3ppm / ℃, Q×f value is 323,200GHz(f 0 =7.535GHz).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com